How to create a business process map

Business Process Mapping is an essential part of any process improvement strategy, so here is our step by step guide to doing it successfully.

Summary

- Business process mapping visualizes how your business operates - It reveals strengths, weaknesses, and improvement opportunities by creating top-down views of workflows; essential for continuous improvement (BPM), fixing inefficiencies (BPI), and major redesigns (BPR)

- Mapping dates back to 1921 but remains critical today - Frank and Lillian Gilbreth introduced flow process charts showing that entire processes must be visualized all at once before making changes; Procter & Gamble was among the first to adopt this practice which became industrial engineering standard

- Multiple mapping types serve different purposes - Process flowcharts for simple visualization, swimlane diagrams to show team responsibilities, value stream maps for lean six sigma analysis, SIPOC diagrams to focus on essentials, and BPM software to track performance in real-time

- Mapping enables problem-solving and risk management - Visualization helps identify inefficiencies, bottlenecks, and missed deadlines; allows establishing best practices, ensuring compliance, and managing risks by seeing when and where things go wrong. See how Tallyfy maps processes

Processes are at the heart of the way every business operates. The greater understanding of what they are, how they function and what impact they have, the better you’ll manage your business.

This is where Business Process Mapping comes in.

Visualizing the processes helps you get a better understanding of how your business functions, as well as your strengths and weaknesses. This, in turn, helps you make the business more efficiently.

This guide will walk you through everything you need to know about Business Process Mapping: history, benefits, and a step-by-step guide on how to use it to better your business.

Business Process Mapping is the visualization of business processes, allowing for a more top-down view on how the business works.

On its own, the main benefit of business process mapping is the introspection. You get a better understanding of how your business works.

It can, however, also be essential for…

- Business Process Management (BPM) - A methodology of constantly re-assessing the efficiency of your processes. It’s impossible to do this without having the processes mapped out

- Business Process Improvement (BPI) - Methodology (or initiative) aimed at identifying inefficient or wasteful processes and improving on them

- Business Process Re-Engineering (BPR) - Using new technology or methodology to make major changes (or completely tear down) old processes

Process mapping dates back to the early flow process chart by Frank and Lillian Gilbreth which they unveiled in 1921 as part of his prophetically-titled talk Process Charts—First Steps in Finding the One Best Way.

They introduced it by saying:

Every detail of a process is more or less affected by every other detail; therefore the entire process must be presented in such form that it can be visualized all at once before any changes are made in any of its subdivisions.

The flow process chart uses graphics and symbols to represent the flow of activities within a process. After the Gilbreths’ talk to the American Society Of Mechanical Engineers, it was adopted as standard practice in much of the industrial engineering industry across America.

ASME officially introduced a range of symbols in the Standard for Process Charts in 1947.

One of the first businesses to adopt Business Process Mapping was Procter & Gamble, thanks to Art Spinanger. He had learned about it from industrial engineer Allan H. Morgensen, who had in turn based his efficiency lectures upon the original concept by the Gilbreths.

To get a better feel of how Business Process Mapping works, here’s a process map for making breakfast:

Types of business process maps

There are several types of business process maps you can use, each come with their own pros and cons.

Here’s a brief summary of each…

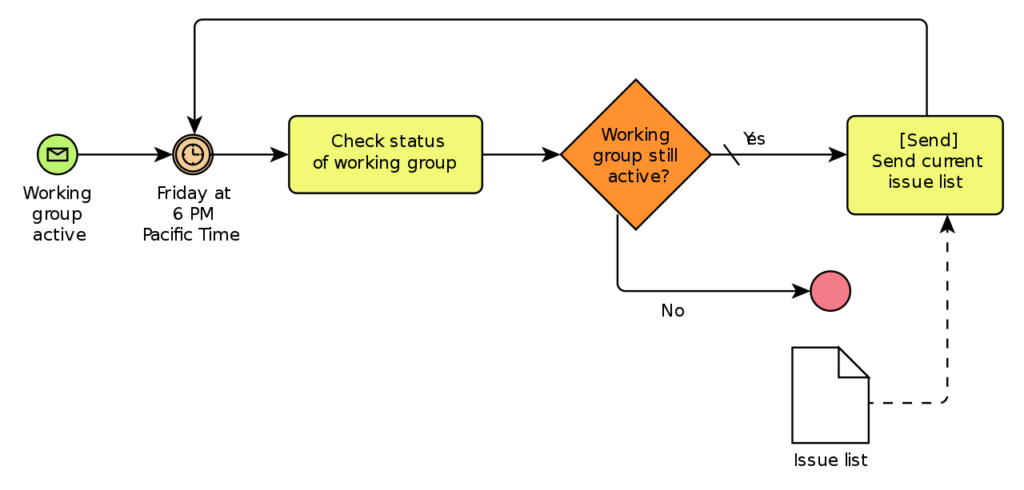

Process Flowcharts - These are the most common types of business process maps as they most closely resemble what the Gilbreths introduced almost a century ago.

They can be hand-drawn or created in software like Office. The downside of these methods is the lack of flexibility or adaptability.

But the simplicity and familiarity have their own appeal too, so flowcharts won’t be going away anytime soon.

Source: wikimedia

Want to learn more? Check out our guide on how to create & use process flowcharts

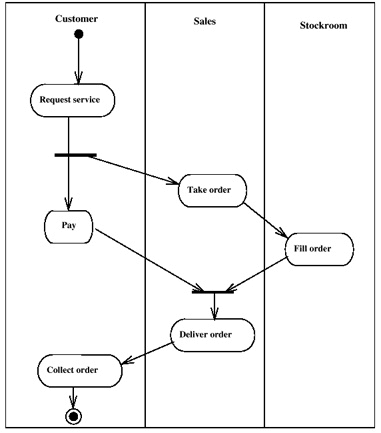

Swimlane Diagram - This one functions almost identically the same as a generic flowchart.

The main difference is that with the swimlane diagram, each of the steps is divided between different teams or individuals who are responsible for them. This makes it a very clear system for processes that need to be mapped out in this manner.

Source: flickr

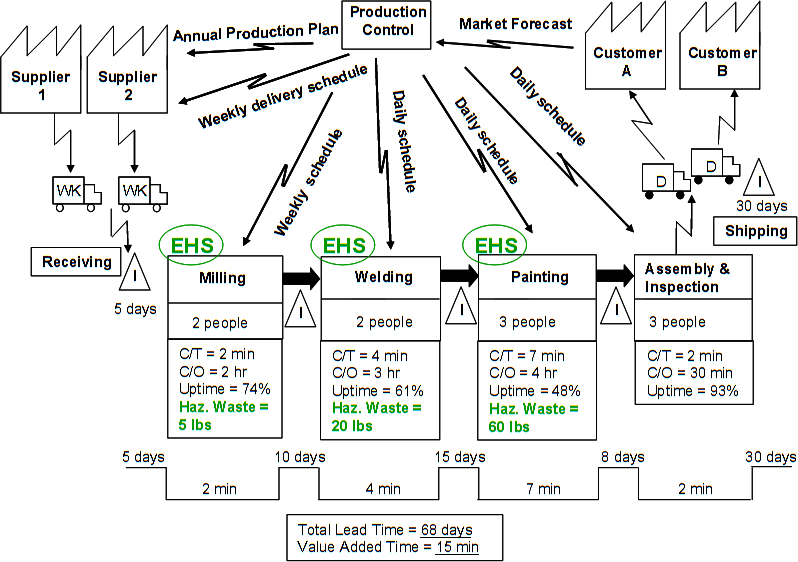

Value stream map - Another alternative to the flowchart, a value stream map is often used in lean six sigma applications.

They are much less straightforward to analyze at a glance. This makes them potentially more useful for a more in-depth look into a process, but also makes them less commonly used.

Source: wikimedia

Want to learn more? Read up our article on the ins and outs of value stream mapping

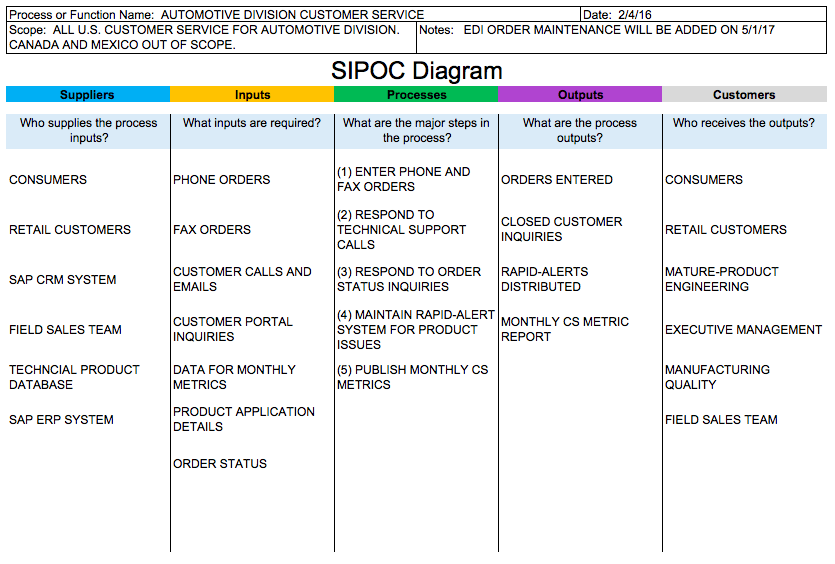

SIPOC - This stands for Supplier Inputs Processes Outputs Customer.

It is a very simplified process map that strips away 99% of the information to focus on the essentials of the process and the people involved.

Source: sipoc.info

Want to learn more? Read up our guide on SIPOC diagrams.

Software - The most high-tech tool for process mapping is Business Process Management Software.

The added benefit here is that the software also allows you to keep track of the processes post-mapping: how the process is performing, if there are any bottlenecks, missed deadlines, etc.

On the other hand, it can also be used by your employees to keep track of their tasks and to-dos. This allows for easier process optimization since you can see when and where anything goes wrong.

Want to learn more about process management software? Check out our guide to some of the best BPM tools out there.

If you want to move beyond static diagrams and create living process documentation that teams actually follow, process documentation software can transform your mapping efforts into trackable, improvable workflows.

Tallyfy is the only product available that does Process Documentation and Process Tracking in one

Top benefits of business process mapping

Business Process Mapping comes with countless benefits for your business.

In fact, chances are, you’re leaving free money on the table just because you’re not doing process mapping!

The following are some benefits you’re most likely to receive:

Visualization of roles

This should go without saying - every once in a while, you end up in a situation where no one knows what’s going on with a certain process.

Who’s in charge of what? Why is the new report not ready? Why did the manufacturing line just blow up?

A business process map helps visualize the responsibilities on everyone’s part - it’s going to be clear who’s in charge of what for each part of a process.

Problem solving

Spotting the problem is easy - just look at what blew up.

Finding the source, however, tends to be more difficult. A process map visualizes the entire process that led to the bottleneck, making it a lot easier to spot what, exactly, went wrong. At Tallyfy, we’ve seen teams spend weeks chasing symptoms before realizing the root cause was three steps upstream in a handoff nobody documented.

Risk management and compliance

As well as identifying areas that are causing inefficiencies, Business Process Mapping is a great tool for spotting potential risks caused by processes that leave the company open to legal or health and safety problems.

If you end up missing a step that’s critical to some governmental regulations, it can be extremely hazardous to the company. I think this is probably the most overlooked benefit of mapping. It creates danger for the employees or the environment, which in turn, leads to fines. One mid-sized services company told us they discovered staff were “performing outdated or irrelevant tasks without knowing” - their process mapping initiative revealed so much redundancy that they eliminated 50 positions while actually improving quality and quadrupling revenue.

For the same reasons, process mapping can be a valuable resource when it comes to supplying evidence for regulatory standards in terms of compliance.

Establishing best practice

Once Business Process Mapping has been introduced to a company and a process has been mapped and optimized accordingly, the map can be used across the board as evidence of best practice and an exemplar for the rest of the business processes.

This brings some uniformity to the way processes work within the organization. It rewards those who put in the initial effort, as well as demonstrating the importance of the mapping.

If on the other hand, a process is underperforming, it’s easier to try out different ways to carry it out & compare it to the original benchmark.

Showing the big picture

In any business larger than a handful of staff, it is inevitable that a silo mentality will develop over time. Staff at all levels will lose sight of the big picture of what the business is attempting to achieve.

Even when you drill down to just one process involved in the organization, Business Process Mapping can help everyone understand the big picture and get re-engaged with the vision and the steps required to achieve it.

Business Process Mapping allows your employees to get a very good sense of what’s going on within the business - both on a day-to-day level and on the larger scale. This, in turn, makes it easier to achieve the bigger goals.

Steps to successful business process mapping

Want to give Business Process Mapping a try?

Well, here’s how to do it…

Step #1: Identify the process to be mapped

While it’s good to map out all of your processes, you have to start from somewhere.

So, the first step is to pick the process you’d want to start working with.

You probably want to start with the process that’s critical to your business, the improvement of which can easily be tracked with numbers.

Generally, however, there are three ways to go about selecting the process:

- Reactive - This is where a process has failed or is majorly underperforming, due to some sort of a bottleneck.

You’d want to carry out mapping here as a means of identifying and fixing the issue.

-

Strategic - This is when the mapping is being done as part of a high-level strategic overhaul, in which case the process chosen will be one that is considered integral to that strategy and the organization’s goals.

-

Customer-Focused - And finally, this is when the process is selected for mapping because it is key to ensuring that customer satisfaction is improved and fixing problems or inefficiencies within that process will deliver a visible boost for customers.

Step #2: Bring together the right project team

Even if you know the ins-and-outs of your business, you’ll still want to cooperate with the field employees who work with the process.

Their input can be priceless on this, as they might already have a few ideas on how to improve the processes. A digital strategy consulting firm COO told us: “By forcing ourselves to write out the processes we can now ensure that steps are not missed or done out of order. Generally, there are fewer mistakes.” Frontline teams often spot inefficiencies that management never sees.

In addition, they’ll also act as evangelists for the initiative. Change tends to be scary for everyone - and a process mapping initiative might seem threatening to some of the field employees.

Who knows, maybe someone’s position will have to be cut to increase efficiency? Involving them in the initiative will make sure that their voices are heard, putting the fear of being left out to rest.

You might also want to get someone from the senior management on the team. Without one, you might have to ask for management approval on even the smallest changed you’d want to carry out.

Want to get buy-in for company change? You can use change management models such as the ADKAR model or Bridges Transition Model to get your employees used to change.

Step #3: Gather information

Once you’ve worked out what you want to achieve and which process you are going to map, you need to start gathering the required information.

All of the steps need to be identified and recorded, capturing which job title does which step, when and how. Gather as much detail as is required to have a complete process map.

At this first stage, it is best to err on the side of getting too much information and filtering it down as you work through it, rather than end up with not enough and have to revisit the process.

Here’s something that often surprises people: when you actually measure the time work spends in a process, only about 10-15% of that cycle time typically adds real value. The rest? Waiting in queues, sitting in inboxes, getting approvals nobody reads, bouncing between systems. That’s why one of the best information gathering techniques is what some call “process stapling” - you literally follow a single piece of work through the entire process, almost like stapling yourself to the paperwork. Walk the floor. Sit with the people doing the work. Watch where things pile up, where handoffs get messy, where people create workarounds nobody documented. The gap between how managers think work flows and how it actually flows can be startling. Conference room process maps almost always look cleaner than reality.

Step #4: Interview key figures

As part of the information gathering, you need to talk to the people involved to find out what their understanding of their process is. Use what you get back from them to identify the problems and the opportunities to improve.

You have to stay aware that staff will bring their own feelings and agendas into their descriptions of the way things work. But it’s still important to listen to them to get a better understanding of the process that you wouldn’t be able to get any other way.

Step #5: Produce the baseline business process map

With all of the necessary data, it’s time to draw up the baseline map.

This shows how the process is currently operating, flaws and all. This will demonstrate the way the process works before any improvements have been made.

It acts as both the evidence for what needs to change. It can also be used to compare and contrast after a new process map has designed and implemented and as a guideline for mapping further processes in the future.

Using Business Process Mapping software is the easiest, more consistent, efficient and scalable way to draw up the map, as it will also have the tools to help you analyze the findings.

If you are not using software, here are some of the basic components of any Business Process Map that you will likely need to include:

- Process - This is the overall workflow

- Tasks - Each step of the workflow, usually something that needs to be actioned by a member of staff or a system

- Flows - These are the connecting lines and arrows that describe how the work flows from task to task

- Events - These are the triggers or gateways that begin, redirect or end a process

- Participants - As the name suggests, these are the people or systems involved in the process

Step #6: Analyze and identify areas for improvement

Even though you have your process map in hand, your work isn’t really done.

What’s the point of the map, after all, unless you actually learn something from it and make some improvements?

From your previous investigations, you’ve probably already identified a flow or two within the process as-is. With the map, however, you can find a lot more.

From then on, you’d want to carry out BPI or BPR, finding different ways to improve the process (or maybe completely restructure it). Once you have an idea or two on how that could work, you’d want to implement the new processes on a smaller scale.

If it works better than the old, apply it to the rest of the organization.

If your employees are having difficulties adapting to the new process, you could give them a small nudge by creating and communicating a new process map.

Not sure how to find and apply improvements? Learn about the 4 most common ways to improve processes.

Step #7: Monitoring improvements

Whether the Business Process Mapping is being done as part of a larger overhaul of processes within your organization or not, you need to start proper monitoring of how your improved process is functioning.

Only through constant monitoring and optimization can you expect your processes to continue to be refined and improved.

Business Process Mapping cannot be a one-time thing that will be expected to fix all of your problems.

Conclusion

Now that you know the theory behind process mapping, it’s time to carry it out within your organization.

Theory, after all, will only get you so far.

If you’re looking for the right software to give you a hand with process management - anything from mapping to re-engineering - you might want to give Tallyfy a try & schedule a free demonstration!

Process mapping templates to get you started

Related questions

What are the four steps of process mapping?

The four main steps of process mapping are as follows: defining the scope of the process to be mapped, collecting information from the participants who carry out the work, drawing the process map with simple geometric elements, and analysing the process map in order to identify avenues for improvement.

It’s like creating a treasure map - you first decide where you want to search, ask your pirates who have already been there, chart a path, and discover shortcuts.

What are the six main methods to create business process maps?

There are six main diagram types: flowcharts (the classic boxes and arrows), swimlane diagrams (depicting who does what), value stream maps (where waste and value are identified), SIPOC diagrams (describing who supplies to whom), detailed process maps (a step-by-step breakdown) and cross-functional flowcharts (depicting how departments work together).

Each method captures a unique portion of your process, like shooting the same scene, with different camera angles.

How to write a business process map?

Begin by observing the process in action and discussing it with folks who do it daily.

List out each step in order. Use basic shapes (circles for start/end, rectangles for actions, diamonds for decisions), connect them with arrows, and include clear labels.

Keep it simple - if your map looks like a plate of spaghetti, you are complicating it too much.

What are the various kinds of process mapping techniques?

Beyond the simple flowchart, you have things like hierarchical process maps (which show different levels of detail), spaghetti diagrams (which are used to track physical movement), BPMN (Business Process Model and Notation, which is the standardized mapping of a process), and mind maps (which can be used for brainstorming process), to name a few.

They offer different solutions - they’re like tools in your toolbox.

What is the tool for business process mapping?

Modern process mapping is typically done in digital tools such as Tallyfy, which enables teams to map, share and iterate on processes in real-time.

Tools as simple as Microsoft Visio or even pen and paper can of course be used, but with specialized workflow software you can transform static maps into living, breathing processes that teams can actually follow through and iterate.

What is the difference between business process mapping and business process modeling?

Process mapping, quite literally, is a snapshot of how work is happening today - it describes the current state.

Process modeling is much more like architectural planning - it guides how work should happen in the future.

Mapping describes reality, while modeling helps us to visualize options and test out changes before we enact them.

Why is business process mapping needed?

Process mapping helps make invisible work visible inside organizations. That’s the key.

It exposes bottlenecks, duplicative steps, and levels of improvement.

It’s kind of like X-ray vision into your business - you can see what’s wrong, bring in new people faster and make sure everyone understands how things should be done.

How often should you update process maps?

Process maps ought to be living documents, updated whenever significant changes occur or at least quarterly reviewed.

Your process maps, just like your GPS does, will need some updates whenever you find better ways of working, new tools, or new rules your team were not aware of.

What makes a process map effective?

An effective process map is clear enough for a neophyte to comprehend, detailed enough to confer utility, but simple enough to present at a glance.

It should use standard symbols, include all major decision points and illustrate step by step how work flows from one end to the other.

So think of it as a good recipe with enough details to get the job done but not too much that it is unreadable.

How do you identify processes worth mapping?

Attention to processes that affect customer satisfaction, take substantial resources or have repetitive issues.

Seek out processes that span department lines or ones that teams frequently argue over.

These items are akin to the main roads the business must know - the most important paths to take and where to map first.

What common mistakes should you avoid in process mapping?

Some common pitfalls include making maps too complex, failing to include exceptions and error handling, not bringing in the right people and creating maps that simply sit in a drawer collecting dust.

The most effective process maps are living tools that the teams truly use, not flawless diagrams that collect dust.

How do you get team buy-in for process mapping?

Involve the team from the get-go, tell them how the mapping is going to make life easier, and use their input in creating the maps.

Deliver early successes by solving easy problems the mapping highlights.

You can think of it like building a house together - if you build a house and share the blueprint, it’s up to everyone to see the value there if they’re going to help build the house.

About the Author

Amit is the CEO of Tallyfy. He is a workflow expert and specializes in process automation and the next generation of business process management in the post-flowchart age. He has decades of consulting experience in task and workflow automation, continuous improvement (all the flavors) and AI-driven workflows for small and large companies. Amit did a Computer Science degree at the University of Bath and moved from the UK to St. Louis, MO in 2014. He loves watching American robins and their nesting behaviors!

Follow Amit on his website, LinkedIn, Facebook, Reddit, X (Twitter) or YouTube.

Automate your workflows with Tallyfy

Stop chasing status updates. Track and automate your processes in one place.