What, Exactly, is Continuous Improvement?

Continuous improvement is, as the name suggests, a practice of constantly re-examining and improving processes. At a glance, the whole concept might seem a bit of a buzzword. You keep hearing the word thrown around, but no one really mentions what it involves doing. And as we all know, the theory doesn’t get you too far in the business world. All the confusion with continuous improvement is because it’s not something that you “do.” Rather, it’s a way a company operates. Adopting continuous improvement in a company means two things…- Focus on Growth – The company should have an ongoing focus on incrementally improving their processes, services or products. Meaning, perfecting the way you do things on-the-go instead of carrying out one-off change initiatives.

- Creating a Culture of Improvement – More often than not, it’s the employee on the shop floor who’s an expert on company processes, not the management. Continuous improvement should be the responsibility of everyone in the company (not just for the process improvement team).

- Business Process Management (BPM) – A methodology of process re-evaluation and improvement. More or less the same thing as continuous improvement. The minor difference is that continuous improvement is more of a “philosophy” that a company should be based on, while BPM is a concrete set of tools and techniques. You can use BPM as a means of creating a culture of continuous improvement, but it doesn’t necessarily work the other way around.

- Business Process Improvement (BPI) – The act of analyzing, streamlining and improving a single process. Continuous improvement means carrying out a BPI initiative whenever there’s need for it.

- Business Process Reengineering (BPR) – Rather than improve an existing process, you re-create it using a new technology or methodology.

Benefits of Adopting Continuous Improvement

Continuous improvement processes allow businesses to uncover problems and find ways to fix them. Small, positive changes made over time can dramatically impact a business’s overall process. Here are a few ways continuous improvement can benefit your business over time: Increased Productivity & Profits By incrementally improving processes, your business will start seeing a much higher product per input. This, as a given, makes your entire organization more efficient, which finally translates into higher profits. Employee Morale and Accountability Oftentimes, your employees can have a lot of ideas on how to improve processes or products. A rigid organizational structure, however, can shut them down and kill their motivation. In a company with the culture of continuous improvement, on the other hand, every employee is key to organizational growth. Allowing your employees to walk the extra mile and actually contribute to progress makes them feel valued, increasing overall morale and accountability. Greater Agility An organization has to be changing at all times to keep up with the competition. If your employees are used to change on a regular basis, they won’t be phased during times of crisis and change.How Continuous Improvement Works

Getting your company used to continuous improvement isn’t easy. You can’t just go up to your employees one day and tell them “the company will function differently from here on out.” Making any kind of change in an organization is hard, and this is especially true if you’re doing something so major. But of course, you need to start somewhere. First things first, you’ll need to let your management know about the initiative. Meaning, any suggestions on improving company processes will be welcomed by the management. Then, you’ll need to allow for the establishment of business process improvement initiatives. Once someone suggests a plausible way to improve a process, you’ll need to assign an individual or team (depends on skills needed to change the process) in charge or improving it. To help get this right, you can use tried-and-tested continuous improvement tools to move things forward…Kaizen

Kaizen is a Japanese word that means “change for the better.” The methodology was first used during the World War 2 by Japanese businessmen, eventually spreading around the world. Masaaki Imai, a Japanese management consultant helped spread awareness of the Kaizen methodology in his book, Kaizen: The Key to Japan’s Competetive Success. To establish a culture of continuous improvement, he recommends using 2 types of processes: Quality Teams and Kaizen Corners. The first is a team of experts specializing in process improvement through statistical tools and software. They’re for the type of improvements that you need expertise on and not something the average joe can just suggest. Kaizen Corners, on the other hand, is a place where every single employee can hand in suggestions on how to improve processes. Masaaki recommends splitting the implementation of a Kaizen Corner into three stages…- Stage One – All suggestions made by employees are considered and implemented. This is to show the team that everyone’s input will be valued.

- Stage Two – Employees are trained on how to properly analyze current processes and make better suggestions.

- Stage Three – Offer an economic incentive for employees to contribute towards process improvements.

- Plan

- Do

- Check

- Act

Conclusion

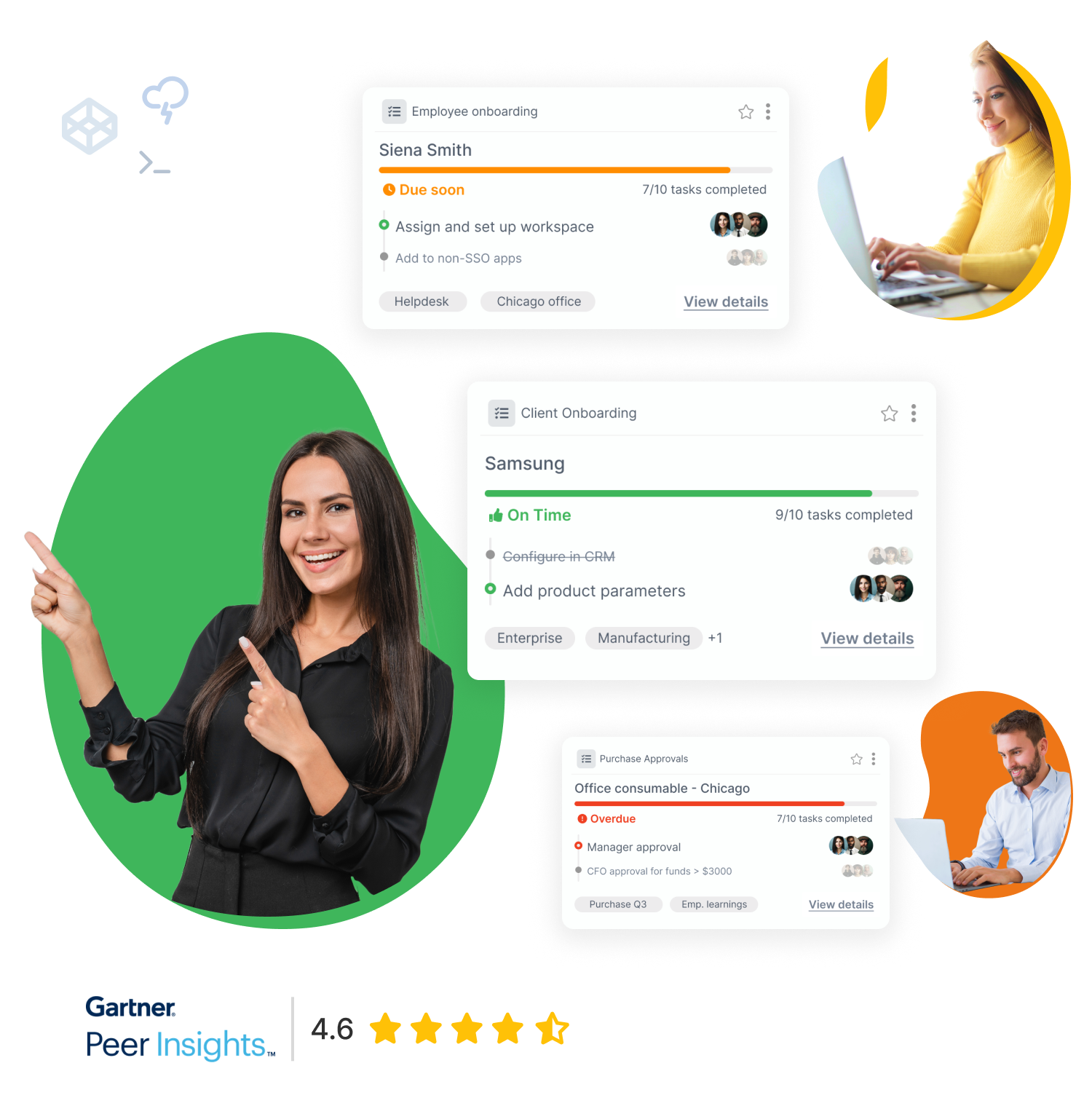

Even if your business is doing phenomenally now, that isn’t destined to last forever. A changing economy, new technology, budget concerns, and staff shortages are all dynamics that will eventually force you to make adjustments. An organization that embraces continuous improvements will be able to act on these changes and stay on course. A rigid, authoritarian company, on the other hand, will not. If you need help creating a culture of continuous improvement in your company, workflow management software can help. Telling your employees that they’re going to be doing something differently is one thing, enforcing it is something completely different. Tallyfy can digitize your processes, create changes and track them from start to finish.Related Questions

What is meant by continuous improvement?

Continuous improvement is a simple idea that means making things better, bit by bit, every single day. Think of it like leveling up in a video game – you don’t become super powerful overnight, but rather through small, steady progress. In business and life, it means never settling for “good enough” and always looking for ways to do things better, smarter, or faster.

What are the 4 Ps of continuous improvement?

The 4 Ps make continuous improvement super easy to remember: Purpose (knowing why you’re making changes), People (involving everyone in the improvement process), Process (understanding how work gets done), and Performance (measuring if changes actually help). It’s like having a recipe for making things better – you need all four ingredients for the best results.

What are the 5 steps of the continuous improvement process?

The 5 steps are like a treasure map for making things better: Plan (figure out what needs fixing), Do (try out your solution on a small scale), Check (see if it worked), Act (make it permanent if it helps), and Repeat (start over with something new to improve). Think of it as a never-ending game of “let’s make things awesome.”

What are the 3 pillars of continuous improvement?

The 3 pillars are like the legs of a tripod: Transparency (being open about problems), Communication (talking about ideas and solutions), and Accountability (making sure improvements actually happen). Without any one of these, your improvement efforts might topple over like a wobbly chair.

How is continuous improvement different from a one-time change?

Think of one-time change as a giant leap, while continuous improvement is like taking small steps every day. One-time changes are like trying to get fit by running a marathon without training, while continuous improvement is like going for a short walk each day and gradually building up to longer distances.

Why do most continuous improvement programs fail?

Many programs crash and burn because people treat them like a sprint instead of a marathon. Common pitfalls include trying to change too much too fast, not getting everyone involved, or forgetting that improvement needs to become a daily habit – like brushing your teeth – rather than a one-time project.

How do you measure continuous improvement?

Measuring improvement is like keeping score in a game. You can track things like how much time you save, how many mistakes you catch, or how happy your customers are. The key is picking measurements that matter to your goals – just like counting calories only matters if you’re trying to lose weight.

What role does leadership play in continuous improvement?

Leaders are like gardeners in continuous improvement – they create the right environment for growth. They need to water the plants (provide resources), pull the weeds (remove obstacles), and make sure there’s enough sunlight (give encouragement and support). Without good leadership, improvement efforts can wither away like unwatered plants.

How can you create a culture of continuous improvement?

Creating an improvement culture is like starting a trend – it needs to be cool and catching. Make it safe to point out problems, celebrate small wins, share success stories, and make improvement part of everyday conversation. Soon enough, looking for better ways to work becomes as natural as checking your phone.

What’s the difference between kaizen and continuous improvement?

Kaizen and continuous improvement are like identical twins – they look different but mean the same thing. Kaizen is just the Japanese word for continuous improvement, literally meaning “change for better.” The principles are the same: make small, steady improvements every day.

How do you sustain continuous improvement over time?

Keeping improvement going is like maintaining a healthy lifestyle – it needs to become a habit. Build regular check-ins, create improvement routines, celebrate progress, and make it fun. The secret is making improvement feel as natural as your morning coffee, not like an extra chore.

What tools are commonly used in continuous improvement?

Think of improvement tools like a superhero’s utility belt – each one has its special power. You’ve got process maps (like GPS for your work), suggestion systems (idea collectors), visual management boards (progress trackers), and problem-solving techniques (like having a Swiss Army knife for fixing issues). The key is picking the right tool for each job.