Lean Six Sigma is a powerful methodology that combines Lean Manufacturing and Six Sigma to eliminate waste and reduce variation in processes.

- Lean Six Sigma aims for near perfection, with only 3.4 defects per million opportunities.

- It focuses on improving customer satisfaction by eliminating variation and waste.

- Organizations across industries have saved billions of dollars using Lean Six Sigma.

- Implementing Lean Six Sigma requires organization-wide commitment and a systematic approach.

Who is this article for?

- Manufacturing companies looking to improve efficiency and reduce costs

- Service-oriented businesses aiming to enhance customer satisfaction

- Healthcare organizations seeking to streamline processes and improve patient care

- Financial institutions wanting to reduce errors and improve operational performance

- Quality Managers and Process Improvement Specialists

- Operations Managers and Business Analysts

- CEOs and executives interested in driving organizational excellence

- Lean Six Sigma practitioners and those considering certification

What is Lean Six Sigma?

Lean Six Sigma is a powerful methodology that combines two distinct but complementary approaches: Lean Manufacturing and Six Sigma. This integrated approach aims to improve performance by systematically removing waste and reducing variation in organizational processes. According to Snee (2010), Lean Six Sigma is a holistic improvement methodology that addresses enhancement in all parts of an organization. It focuses on improving the flow of information and materials through processes while also enhancing value-adding steps that create products or services for customers.The Origins of Lean Six Sigma

To understand Lean Six Sigma, it’s essential to look at its components separately: Lean Manufacturing: Originated from Toyota’s production system, Lean focuses on eliminating waste (non-value-added activities) and improving flow in processes. Six Sigma: Developed by Motorola in the 1980s, Six Sigma aims to reduce variation and defects in processes, striving for near-perfection. The integration of these two methodologies creates a powerful approach that addresses both efficiency and quality simultaneously.Quote

Variation is evil.

What are the Key Principles of Lean Six Sigma?

Lean Six Sigma is built on several fundamental principles:- Focus on the Customer: Understanding and meeting customer needs is paramount.

- Identify and Understand Value Streams: Mapping processes to identify value-adding and non-value-adding activities.

- Remove Waste: Eliminating activities that don’t add value to the customer.

- Manage, Improve and Smooth the Process Flow: Ensuring processes run smoothly and efficiently.

- Manage by Fact and Reduce Variation: Using data to make decisions and reduce process variations.

- Involve and Equip the People in the Process: Engaging employees in improvement efforts.

- Undertake Improvement Activity in a Systematic Way: Following a structured approach to problem-solving.

Tip

When implementing Lean Six Sigma, start with small, manageable projects to build momentum and demonstrate value before tackling larger, more complex processes.How Does Lean Six Sigma Work?

Lean Six Sigma typically follows the DMAIC (Define, Measure, Analyze, Improve, Control) methodology for process improvement. This structured approach ensures that improvements are data-driven and sustainable.- Define: Clearly articulate the problem, goals, and scope of the project.

- Measure: Collect data to establish baseline performance and identify potential causes.

- Analyze: Use statistical tools to identify root causes of problems.

- Improve: Develop and implement solutions to address root causes.

- Control: Establish measures to sustain improvements over time.

Fact

In 2006, Motorola reported saving $17 billion using Six Sigma methods, demonstrating the significant financial impact of this methodology (Snee, 2010).What are the Benefits of Implementing Lean Six Sigma?

Organizations that successfully implement Lean Six Sigma can expect numerous benefits:- Improved Quality: By reducing variation and defects, product and service quality increases significantly.

- Enhanced Customer Satisfaction: Consistent quality and improved processes lead to higher customer satisfaction and loyalty.

- Cost Reduction: Eliminating waste and improving efficiency often results in substantial cost savings.

- Increased Productivity: Streamlined processes and reduced errors lead to higher productivity.

- Employee Engagement: Involving employees in improvement efforts can boost morale and job satisfaction.

- Data-Driven Decision Making: Lean Six Sigma promotes a culture of using data to make informed decisions.

How to Implement Lean Six Sigma in Your Organization?

Implementing Lean Six Sigma requires careful planning and execution. Here are some key steps to consider:- Secure Leadership Commitment: Top management support is crucial for success.

- Assess Organizational Readiness: Evaluate your organization’s culture, resources, and capabilities.

- Provide Training: Educate employees on Lean Six Sigma principles and tools.

- Start with Pilot Projects: Begin with small, manageable projects to demonstrate value.

- Build a Support Structure: Establish roles like Black Belts and Green Belts to lead projects.

- Communicate Success: Share wins and lessons learned to build momentum.

- Integrate with Business Strategy: Align Lean Six Sigma efforts with overall business goals.

Tip

When selecting Lean Six Sigma projects, prioritize those that align closely with your organization’s strategic objectives and have a clear potential for significant impact.What Challenges Might You Face When Implementing Lean Six Sigma?

While Lean Six Sigma can bring significant benefits, organizations may encounter several challenges during implementation:- Resistance to Change: Employees may be hesitant to adopt new methods and processes.

- Resource Constraints: Implementing Lean Six Sigma requires time, money, and personnel.

- Lack of Leadership Support: Without top-level commitment, initiatives may falter.

- Difficulty in Sustaining Improvements: Maintaining changes over time can be challenging.

- Misalignment with Organizational Culture: Lean Six Sigma principles may clash with existing cultural norms.

- Overemphasis on Tools: Focusing too much on tools rather than problem-solving and critical thinking.

- Data Quality Issues: Poor data quality can lead to incorrect conclusions and ineffective solutions.

How Can Tallyfy Support Your Lean Six Sigma Journey?

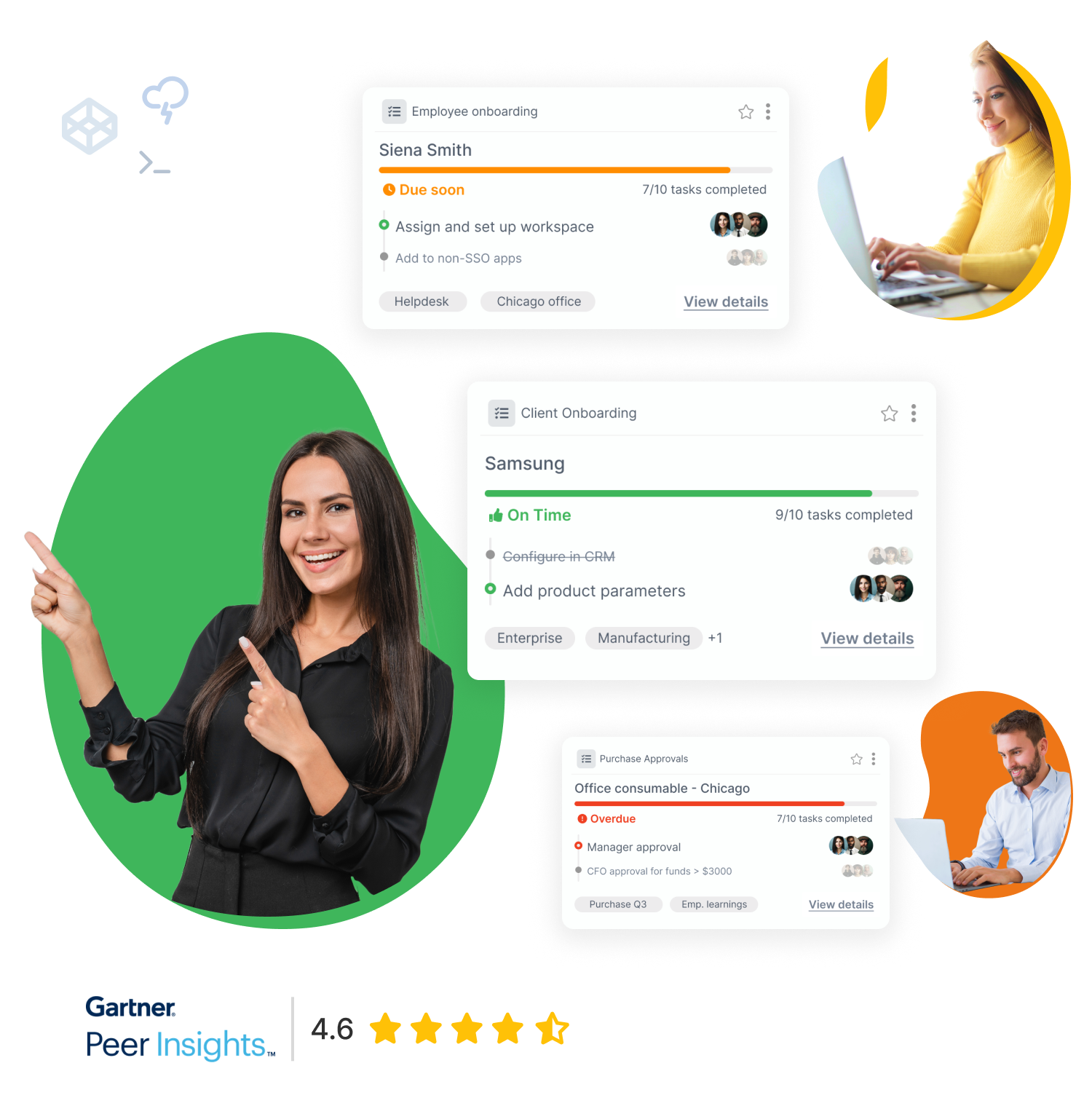

Implementing Lean Six Sigma can be challenging, but using the right tools can significantly ease the process. Tallyfy, a powerful workflow management platform, can support your Lean Six Sigma efforts in several ways:- Process Mapping and Standardization: Tallyfy’s AI-driven documentation feature allows you to easily map and standardize processes, a crucial step in identifying waste and variation.

- Real-time Process Tracking: With Tallyfy’s real-time tracking capabilities, you can monitor process performance and quickly identify bottlenecks or deviations.

- Automated Workflows: Tallyfy’s if-this-then-that feature allows you to set up conditional rules, automating decision points in your processes and reducing variation.

- Data Collection and Analysis: Use Tallyfy’s structured intake forms to collect consistent, high-quality data for your Lean Six Sigma projects.

- Continuous Improvement: Tallyfy makes it easy to update and improve processes over time, supporting the continuous improvement aspect of Lean Six Sigma.

Fact

According to a study by Drohomeretski et al. (2013), organizations implementing Lean Six Sigma reported the best performance in speed, quality, reliability, and cost dimensions.What is Lean Six Sigma?

Lean Six Sigma is a powerful methodology that combines two popular process improvement approaches: Lean Manufacturing and Six Sigma. This hybrid approach aims to enhance organizational performance by reducing waste, minimizing variability, and improving overall efficiency. Developed in the manufacturing sector, Lean Six Sigma has since found applications across various industries, including service-oriented businesses and even government organizations (Furterer & Elshennawy, 2005).How does Lean Six Sigma work?

At its core, Lean Six Sigma integrates the principles of Lean, which focuses on eliminating waste and improving flow, with Six Sigma’s data-driven approach to reducing process variation. This combination creates a robust framework for addressing complex organizational challenges and driving continuous improvement (Snee, 2010). The methodology typically follows the DMAIC (Define, Measure, Analyze, Improve, Control) process, which provides a structured approach to problem-solving and process optimization. By leveraging statistical tools and data analysis techniques, Lean Six Sigma practitioners can identify root causes of issues and implement targeted solutions.Fact

According to a study by Drohomeretski et al. (2013), Lean Six Sigma has been shown to improve performance across multiple dimensions, including speed, quality, reliability, and cost.Why is Lean Six Sigma gaining popularity?

The rise of Lean Six Sigma can be attributed to its ability to address the evolving needs of organizations in an increasingly competitive global market. As Näslund (2008) points out, while Lean Six Sigma may share similarities with its predecessors like Total Quality Management (TQM) and Just-in-Time (JIT), it offers a more comprehensive and adaptable approach to process improvement. One of the key advantages of Lean Six Sigma is its versatility. Initially developed for manufacturing, it has since been successfully applied in various sectors, including healthcare, finance, and education. For instance, Timans et al. (2012) found that small and medium-sized enterprises in the Netherlands have effectively implemented Lean Six Sigma, demonstrating its applicability beyond large corporations.What are the critical success factors for Lean Six Sigma implementation?

Successful implementation of Lean Six Sigma requires careful consideration of several critical factors. Antony (2014) identified key readiness factors for Lean Six Sigma in the higher education sector, which can be broadly applied to other industries:- Strong leadership commitment and support

- Clear vision and strategic alignment

- Effective communication across all levels of the organization

- Adequate resources and training

- Cultural readiness for change

How is technology shaping the future of Lean Six Sigma?

As we look to the future, the integration of advanced technologies is set to revolutionize Lean Six Sigma practices. The emergence of big data analytics, for instance, presents new opportunities for enhancing the effectiveness of Lean Six Sigma initiatives. Gupta et al. (2019) explored the potential of big data in Lean Six Sigma, highlighting how advanced analytics can provide deeper insights and more accurate predictions in each phase of the DMAIC process. Furthermore, the advent of Industry 4.0 technologies, such as the Internet of Things (IoT) and artificial intelligence, is likely to transform how organizations implement Lean Six Sigma. These technologies can enable real-time data collection and analysis, facilitating more agile and responsive process improvements.What are the business benefits of adopting Lean Six Sigma?

Organizations that successfully implement Lean Six Sigma can reap significant benefits. Corbett (2011) found that Lean Six Sigma contributes strongly to each category of business excellence criteria, helping organizations improve their overall performance. Some key benefits include:- Reduced operational costs

- Improved product and service quality

- Enhanced customer satisfaction

- Increased process efficiency and productivity

- Better employee engagement and problem-solving skills

How might future technologies alter our perception of Lean Six Sigma?

As we look ahead, emerging technologies are poised to reshape how we approach and implement Lean Six Sigma. Artificial intelligence and machine learning algorithms could automate many aspects of data analysis and process optimization, enabling faster and more accurate decision-making. Virtual and augmented reality technologies might revolutionize training methods, providing immersive learning experiences for Lean Six Sigma practitioners. Moreover, blockchain technology could enhance transparency and traceability in supply chains, addressing key challenges in process improvement initiatives. The integration of these technologies with Lean Six Sigma principles could lead to more proactive and predictive approaches to process optimization, moving beyond traditional reactive methods. In conclusion, while the core principles of Lean Six Sigma remain relevant, its future evolution will likely be shaped by technological advancements, offering new ways to solve complex business problems and drive continuous improvement in an increasingly digital world.Tallyfy Tango – A cheerful and alternative take

The Lean Six Sigma Comedy Club

Meet Chuck and Belinda, two aspiring comedians who decide to take an unconventional approach to improve their stand-up routines. Chuck: Hey Belinda, I heard you’ve been killing it on stage lately. What’s your secret? Belinda: Oh, Chuck, you wouldn’t believe it. I’ve been using this thing called “Lean Six Sigma” to fine-tune my jokes! Chuck: Lean Six what now? Sounds like a new fad diet for bodybuilders. Belinda: (laughs) Not quite! It’s actually a method for improving processes. I figured, why not apply it to comedy? Chuck: Okay, I’m intrigued. How does it work? Belinda: Well, it’s like a mash-up of two cool concepts. “Lean” is all about cutting the fat – getting rid of stuff that doesn’t add value. And “Six Sigma” is about making things consistent and reducing mistakes. Chuck: So, you’re telling me you’ve turned joke-writing into some kind of science experiment? Belinda: Kind of! I started by mapping out my entire routine, from the moment I step on stage to my final bow. Then I looked for ways to trim the fat – you know, those awkward pauses or jokes that always fall flat. Chuck: (nodding) I see. So, no more of your famous “cricket chirp” moments? Belinda: Exactly! And for the “Six Sigma” part, I’ve been tracking audience reactions and tweaking my delivery until I get consistent laughs. It’s like fine-tuning a laugh machine! Chuck: That’s brilliant! But doesn’t it take the spontaneity out of comedy? Belinda: Not at all! It actually gives me more confidence to improvise. When I know my core material is solid, I can play around more. Chuck: Wow, I’m impressed. So, what’s your process called now? Lean Six Laughma? Belinda: (chuckles) I like that! Or maybe “Stand-Up Sigma”? “Lean Mean Laugh Machine”? Chuck: How about “What is Lean Six Sigma: Comedy Edition”? Belinda: Perfect! You know, Chuck, you should give it a try. I bet we could even apply it to our duo acts. Chuck: You mean, minimize our bickering and maximize the hilarity? Belinda: Now you’re getting it! Just imagine – we could be the world’s first Lean Six Sigma certified comedy duo! Chuck: (laughs) I can see it now – instead of a spotlight, we’ll perform under a giant control chart! Belinda: And our punchlines will be so precise, you could set your watch to them! Chuck: Alright, I’m in. Let’s show the world what happens when you cross a statistician with a stand-up comic! Belinda: Watch out, comedy clubs! The Lean Six Sigma revolution is coming, and it’s bringing laughs with 99.99966% reliability! As Chuck and Belinda high-five and start planning their Lean Six Sigma comedy takeover, little do they know they’re about to spark a whole new trend in the world of stand-up. Who knew that asking “what is Lean Six Sigma” could lead to such hilarious results?

Related Questions

What are the 6 sigma principles?

The 6 sigma principles are the core ideas that guide this powerful quality improvement method. They include customer focus, data-driven decision making, process improvement, proactive management, collaboration, and striving for perfection. These principles help organizations reduce errors, improve efficiency, and deliver better products or services to their customers.What is the purpose of Lean and Six Sigma?

Lean and Six Sigma aim to supercharge business performance by eliminating waste and reducing variation. Imagine a company as a race car – Lean removes unnecessary weight to make it faster, while Six Sigma fine-tunes the engine for peak performance. Together, they create a streamlined, efficient organization that delivers high-quality products or services with minimal errors and maximum customer satisfaction.What are the 6 points of Six Sigma?

The 6 points of Six Sigma, often called the DMAIC process, are Define, Measure, Analyze, Improve, and Control. These steps form a roadmap for problem-solving and process improvement. Think of it as a detective story: Define the mystery, Measure the clues, Analyze the evidence, Improve the situation, and Control the outcome to prevent future problems. This systematic approach helps organizations tackle complex issues and achieve lasting results.What is the concept of Six Sigma?

Six Sigma is like a quest for near-perfection in business processes. The concept revolves around reducing defects to an incredibly low level – just 3.4 defects per million opportunities. It’s like aiming to make only one mistake in 20 years of daily work! This ambitious goal drives organizations to continuously improve their processes, resulting in higher quality, lower costs, and happier customers.What are 6 sigma tools?

Six Sigma tools are like a Swiss Army knife for problem-solving in business. They include statistical techniques, visual aids, and analytical methods that help identify and fix issues. Some popular tools are process maps, cause-and-effect diagrams, control charts, and regression analysis. These tools empower teams to dig deep into data, uncover root causes, and make informed decisions to improve processes and outcomes.What is the Six Sigma rule?

The Six Sigma rule is a fascinating statistical concept that states 99.99966% of all outcomes should fall within six standard deviations of the mean in a normal distribution. In simpler terms, it’s about achieving near-perfection in processes. Imagine if your favorite restaurant got your order right 999,999 times out of a million – that’s the level of quality Six Sigma aims for! This rule sets an ambitious target for organizations to strive towards, pushing them to continuously improve and excel.Six Sigma vs. Lean Six Sigma: What’s the difference?

Six Sigma and Lean Six Sigma are like cousins in the world of process improvement. Six Sigma focuses on reducing variation and defects using statistical tools, while Lean concentrates on eliminating waste and improving flow. Lean Six Sigma combines the best of both worlds, creating a powerful approach that tackles both quality and efficiency. It’s like mixing chocolate and peanut butter – each is great on its own, but together they create something even more delicious and effective!References and Editorial Perspectives

Snee, R., D. (2010). Lean Six Sigma – getting better all the time. International journal of lean six sigma, 1, 9 – 29. https://doi.org/10.1108/20401461011033130

Summary of this study

This foundational study examines how Lean Six Sigma has evolved as a holistic improvement methodology. It emphasizes that successful process improvement requires addressing both information and material flows while creating sustainable improvements through proper infrastructure and treating improvement as a core business process.Editor perspectives

At Tallyfy, we find this research particularly relevant because it aligns with our mission to make process improvement accessible and sustainable. Just as the study emphasizes the importance of proper infrastructure for improvements, our platform provides the digital infrastructure needed to maintain and scale process improvements across organizations.Näslund, D. (2008). Lean, six sigma and lean sigma: fads or real process improvement methods?. Business process management journal, 14, 269 – 287. https://doi.org/10.1108/14637150810876634

Summary of this study

This critical analysis explores whether Lean Six Sigma represents genuine innovation in process improvement or simply repackages existing methodologies. The study emphasizes the importance of taking a systemic approach to organizational change and improvement, rather than just implementing isolated tools and techniques.Editor perspectives

This research resonates deeply with our approach at Tallyfy, where we’ve moved beyond traditional flowcharts to create a truly systemic platform for process improvement. We believe that sustainable change requires more than just tools – it needs a comprehensive digital ecosystem that supports continuous improvement.Drohomeretski, E., Costa, S., E., G., d., Lima, E., P., d., & Garbuio, P., A., d., R. (2013). Lean, Six Sigma and Lean Six Sigma: an analysis based on operations strategy. International journal of production research, 52, 804 – 824. https://doi.org/10.1080/00207543.2013.842015

Summary of this study

This research provides valuable insights into how different process improvement methodologies impact various competitive priorities like speed, quality, reliability, and cost. It demonstrates that Lean Six Sigma offers unique advantages in facilities management, vertical integration, and production planning.Editor perspectives

As workflow automation experts at Tallyfy, we’re particularly interested in how this research demonstrates the multi-dimensional impact of process improvement. Our platform is designed to support these various competitive priorities by providing flexible, adaptable workflow solutions that can be customized to different organizational needs.Glossary of Terms

Lean Six Sigma (LSS)

A methodology that combines Lean principles of waste reduction with Six Sigma’s focus on reducing variation in processes. It aims to improve performance by systematically removing waste and reducing variation while increasing speed and quality in any process.DMAIC

The core process improvement cycle in Lean Six Sigma standing for Define, Measure, Analyze, Improve, and Control. This structured approach helps teams systematically solve problems and improve processes.Value Stream

All activities, both value-adding and non-value-adding, required to bring a product or service from its beginning through to the customer. In Lean Six Sigma, mapping the value stream helps identify areas for improvement.Process Variation

The degree of difference in the output of a process over time. Lean Six Sigma aims to reduce unwanted variation to create more predictable and reliable processes.Continuous Improvement

A long-term approach to work that systematically seeks to achieve small, incremental changes in processes to improve efficiency and quality. It’s a fundamental principle of Lean Six Sigma that emphasizes the ongoing nature of process improvement.