A complete guide to business process improvement tools

Business process improvement tools can help you improve upon, automate and simplify any inefficient processes, which leads to lower expenses.

Summary

- Inefficient processes waste time and create errors - They lead to wasted employee time on useless steps, lower productivity from manual work that could be automated, and mistakes that require rework

- Process mapping visualizes workflows - Flowcharts show exact process steps for standardization and improvement, while tools like SIPOC diagrams analyze value delivery from suppliers to customers, helping identify which steps add value

- Problem-solving tools find root causes - When processes malfunction or fail, these techniques help figure out why things stopped working so you can fix the underlying issues faster instead of treating symptoms

- Four tool categories cover all improvement needs - Process mapping to understand workflows, problem-solving to find failures, improvement methodologies (PDCA, DMAIC) to implement changes, and automation software to eliminate grunt work. See how Tallyfy automates processes

Your organization most likely carries out dozens of processes on a daily basis.

You probably follow a similar set of steps when you onboard a new employee, resolve a customer complaint or create a new report.

Business process improvement tools can serve as a roadmap for improving these processes when they stop working.

Inefficient processes are very harmful to any business, though.

They can lead to…

- Wasted Employee Time - some processes (or process steps) might turn out to be completely useless, taking valuable employee time that could be spent elsewhere.

- Lower Productivity - if your employees are spending time on processes that could be easily automated, they won’t be too happy.

- Errors & Mistakes - inefficiency leads to defects.

To help you analyse and improve your processes, we’ve compiled a complete list of business process improvement tools.

How to use this guide

If you want to learn just about everything about process flowcharts, just read through the whole thing - we’ve got you covered.

If you’re looking for specific sections, though, just jump over to whatever’s relevant!

Process improvement has a lot of different uses - you can, for example, improve an inefficient process.

Or, find the reasons why some of your processes are failing.

We’ve divided the tools into different categories, so if you’re looking for a specific use-case, jump right ahead!

Otherwise, read on…

- Want to improve your processes? Learn how to map them out depending on what you’re using it for.

- Did something stop working? Is the manufacturing department suffering from too much downtime? Learn how to find the causes of failure within your processes.

- Already know both the problems and solutions with your processes? In that case, you need to learn how to execute the changes right.

- Automation can solve a lot of problems. Learn how to use software to automate your processes.

Business process improvement tools - a simple introduction

Everyone wants their business to be as efficient as possible.

Improving your processes, however, isn’t that easy (unless you’re a full-fledged process consultant, of course).

Knowing how to use the right tools, though, will definitely give you a good start.

Since there are a lot of different ways to improve processes, we’ve divided the process improvement tools into 4 categories…

Process Mapping - To makes your processes more efficient, you need to find which process steps add value and which ones don’t.

These tools help you create a step-by-step map of the business process, which in turn, helps you make adjustments.

Problem-Solving - If your processes are malfunctioning, you need to figure out “why?”

These tools help you get to the root cause of any issue, allowing you to put out fires faster.

Improvement Methodologies - Putting a process down into a diagram is easy.

Analysis and improvement, not so much.

These methodologies help you define improvements and put them into practice.

Automation Software - One of the simplest ways to improve a process is to automate whatever you can.

Depending on what you’re automating, you can use different types of software.

Task automation can, for example, take care of that pesky grunt work everyone has to deal with.

If you want to get the best out of your processes, you’ll need to master tools from each category.

For teams looking to put these improvement methodologies into practice, dedicated process improvement software can bridge the gap between identifying inefficiencies and actually fixing them.

Tallyfy is Process Improvement Made Easy

Process mapping

Process mapping is one of the most essential business process improvement tools.

You can’t, after all, improve a process unless you know what exactly it consists of.

There are several different types of analysis tools that help map your business processes.

Some are pretty straightforward.

The process flowchart, for example, details the exact steps you need to take to complete a process.

Others are more top-down, such as the SIPOC diagram.

It helps analyze how you deliver value, starting with the suppliers and ending with the teams and people you serve. Based on feedback from operations teams - with manufacturing (8%) and professional services (10%) leading adoption - this end-to-end view often reveals hidden inefficiencies.

To arm you with the right know-how, we’re going to explain each in detail…

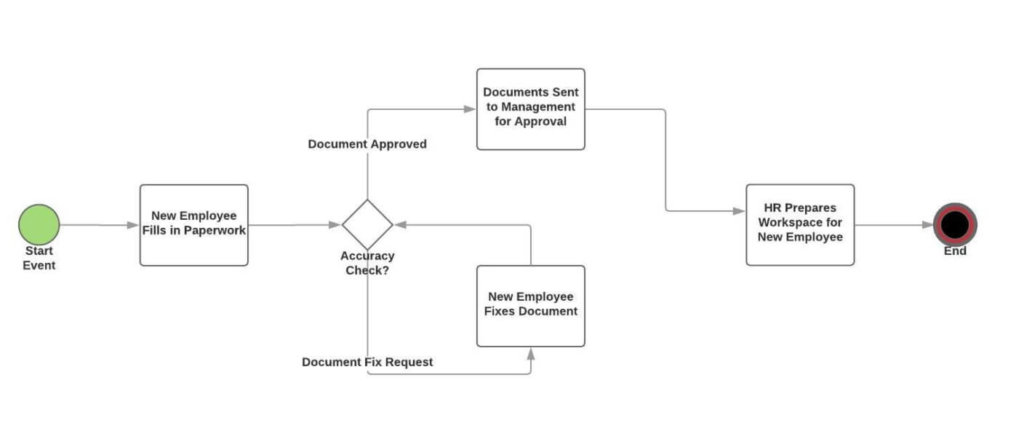

Process flowchart

The process flowchart is, well, a process visualized through a flowchart.

Here’s a simple example…

This business process improvement tool can help with…

- Standardization - Having your employees carry out the best practice process every time without variation.

- Improvement - Removing low-value steps, using tech to automate parts of the process, etc.

- Writing SOPs - Documenting a process through standard operating procedures. SOPs are documents used for either process standardization or employee onboarding (explaining how to carry out the process).

You can create a simple process flowchart by using a pen and paper or use online graphing software such as LucidCharts.

- 3 editable documents

- 60 objects per document

- Unlimited documents

- 1 GB storage

- 3 user minimum

- Unlimited documents

- Advanced security

- Dedicated support

The later is, as a given, the better option.

You want the document to be online and easily accessible by all your employees.

As for the “how,” you can either use the basic symbols…

Or, if you’re an enterprise, you can go for BPMN2 instead.

BPMN is a process mapping methodology that creates a common language for process documentation.

Just about anyone will be able to understand the flowcharts - the management, employees, process consultants, etc.

The down-side here, though, is that BPMN can be hard to learn, so as a start, it might be a better idea to go for the simpler option.

Want to create a process flowchart, but not sure where to start? Check out our step-by-step guide!

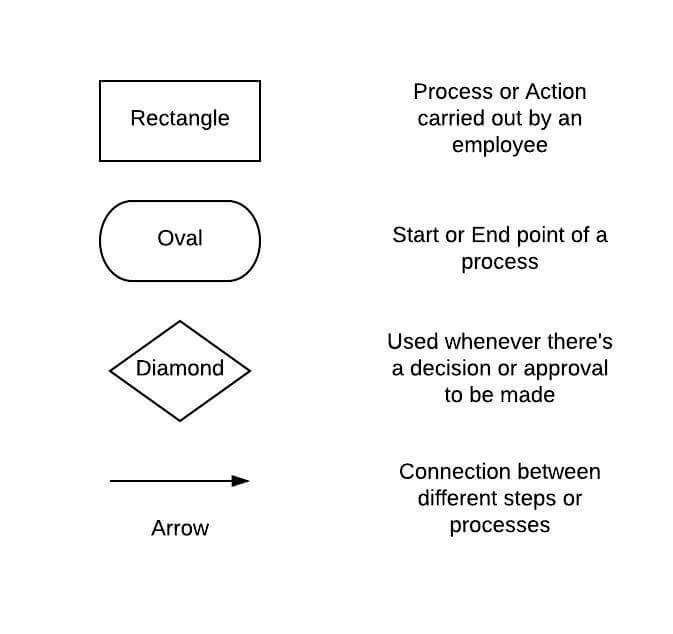

SIPOC diagram

The SIPOC diagram helps with a more top-down analysis.

While the process flowchart helps you define and optimize process steps, SIPOC helps pinpoint how value is delivered to the customer.

The methodology analyses 5 aspects of the process…

Suppliers - Who supplies the process inputs?

Inputs - What inputs are required?

Processes - What are the steps in the process?

Outputs - What are the process outputs?

Customers - Who receives the outputs?

To create the diagram, draw 5 titled after each of the aspects.

Then, list out the respective information.

Or, better yet, simply download a template from the web.

To learn more about the SIPOC diagram, check out our article.

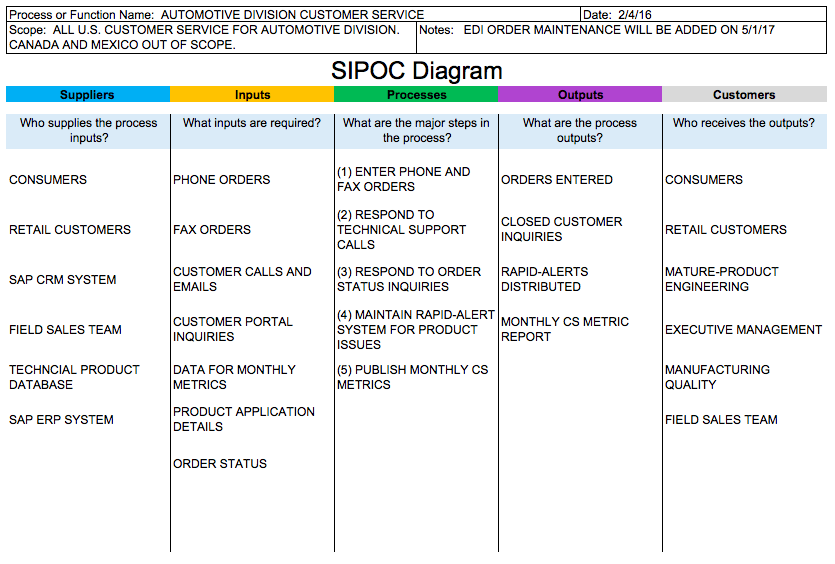

Swimlane diagram

Many business processes will involve people from different teams or departments.

Communication is necessary for these processes to be done accurately and in an efficient way.

But with so many people involved, even the most well thought out processes are at risk of coming undone.

In this situation, a swim lane diagram can be a helpful business process improvement tool.

To create and use a swim lane diagram, you’ll start by listing everyone who is involved in your process (by department) on top to make vertical swim lanes.

Then, you map out the process between different departments.

i.e, Step #1 by department 1, step #2 by department 3, etc.

The end result should look something like this…

Kanban boards

Sometimes the simplest visualization tool is the most powerful. A Kanban board shows work flowing through stages - typically columns like “To Do,” “In Progress,” and “Done.”

What makes Kanban genuinely useful is that it exposes bottlenecks you might otherwise miss. If ten tasks are piling up in “Waiting for Approval” while only two sit in other columns, you’ve found your constraint without needing fancy analysis. The visual nature makes problems obvious to everyone, not just the process improvement team.

Kanban originated in Toyota’s manufacturing, but it works equally well for knowledge work. Marketing teams, IT departments, and customer service groups all benefit from seeing their work laid out visually. The key is limiting work-in-progress - don’t let any column overflow, or you’re just creating a prettier version of chaos.

Problem solving

Putting out fires, while not the most pleasant experience, is unavoidable for any business.

“To err is human,” after all.

You’re bound to make mistakes (and that’s OK).

These business process improvement tools help you find the root cause of problems, allowing you to prevent it from ever happening again.

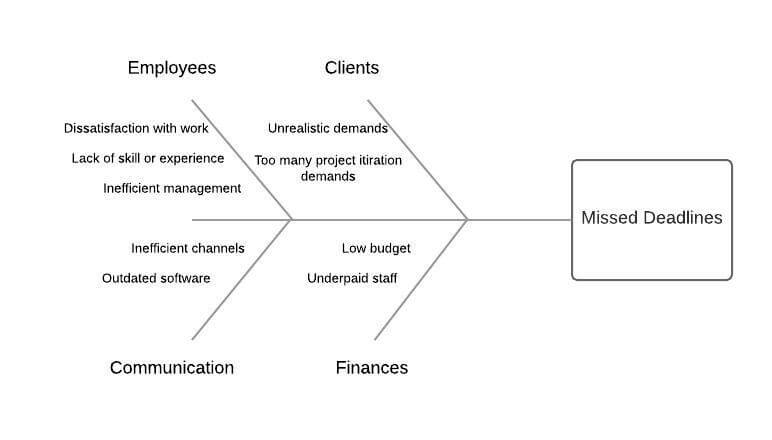

Cause and effect analysis

Cause and effect analysis (also known as the fishbone diagram) is a problem-solving tool that helps you find the root of any problem.

You start with the analysis by identifying the exact problem you’re trying to solve.

Put the problem in a rectangle box and draw a horizontal line to its left.

As an example, let’s say that your software development team frequently misses important deadlines.

On the horizontal line, pinpoint the things that might have a major impact on the process.

In our case, that could be employees (lack of skill?), communication (inefficient practices?), clients (unrealistic demands?), finances (low budget?).

Then, for each factor, identify the possible causes for the problem until you’ve exhausted all the ideas…

At this point, you already have a number of good leads you should start investigating - one of which will turn out to be the root cause of your problem.

Want to learn more about the root cause analysis? Check out our article!

5 whys analysis

This business process improvement tool is more on the theoretical side.

The gist of it is, you keep asking “why” until you’ve discovered the root cause of the issue. It’s deceptively simple.

To give you a better idea of how this works, here’s a more practical example found on the Toyota website (the originator of the 5 whys analysis)…

-

Why did the robot stop?

- The circuit has overloaded, causing a fuse to blow.

-

Why is the circuit overloaded?

- There was insufficient lubrication on the bearings, so they locked up.

-

Why was there insufficient lubrication on the bearings?

- The oil pump on the robot isn’t circulating sufficient oil.

-

Why is the pump not circulating sufficient oil?

- The pump intake is clogged with metal shavings.

-

Why is the intake clogged with metal shavings?

- Because there is no filter on the pump.

For a more in-depth review of the 5 Whys Analysis, head over to our guide.

Failure Mode and Effects Analysis (FMEA)

The problem-solving tools above are reactive - something breaks, then you investigate. FMEA flips that script entirely. It asks: “What could go wrong, and how bad would it be?”

You systematically walk through each process step and brainstorm potential failure modes. For each one, you rate severity (how bad if it happens), occurrence (how likely), and detection (how easily would we catch it before it affects customers). Multiply those three scores together, and you get a risk priority number that tells you where to focus preventive efforts.

The real value of FMEA is shifting from firefighting to fire prevention. Instead of waiting for your shipping process to break down during peak season, you identify that “label printer runs out of ink” has high severity and low detection, so you implement daily ink-level checks before it becomes a crisis. It takes discipline to do this analysis when nothing is currently on fire, but the organizations that do it spend far less time scrambling.

Improvement methodologies

If you’ve already created the process maps, you’re probably wondering - “where do I go from here?”

These process improvement methodologies help you figure out how to find possible improvements and implement them.

PDCA

The PDCA is a process improvement framework developed by Dr. Williams Edwards Deming in the 1950s.

It consists of 4 steps…

Plan

Pin-point the change you’re planning on making.

You can do this through a process improvement tool, such as the process flowchart, or problem-solving tool, such as the 5 Whys analysis.

Do

Once you’ve identified the exact improvement you’re making, you can start with the implementation.

It might be a good idea to do this at a small-scale, though.

Before scaling it company-wide, you need to have proof that the new process is better than the old.

Check

Benchmark the results from the new process to the one from the old.

Keep in mind, though, that a process being efficient short-term doesn’t mean it’s going to be better in the long run.

You might find out that while the new process improves outputs, it can also increase the defect rates, bringing you back to square one.

So, make sure that the new process is better than the old before moving on to the next step.

Act

Once you’re certain that the new process is performing well, you can start scaling it company-wide.

Your job, however, isn’t done - PDCA isn’t meant to be a one-time initiative.

Rather, it’s more of a loop.

You should constantly be on the lookout for process improvements, carrying out PDCA whenever needed.

For a more in-depth overview of PDCA, check out our article.

DMAIC

DMAIC is one of the most popular Six Sigma tools.

It stands for Define, Measure, Analyze, Improve, and Control.

As with PDCA, it’s a framework for process improvement.

- Define - Define the problem. What’s the issue you’re tackling? How does it affect the company?

- Measure - Measure how the process is performing as-is. You’ll need the data as a benchmark for any improvements you make, as well as for helping with analysis.

- Analyze - Analyze the process and find potential improvements. The data you’ve gathered in the previous step might be useful for this. Find any process steps that take either too much time or resources.

- Improve - Put the solutions into practice. As with PDCA, it might be a better idea to start at a smaller scale.

- Control - Make sure that your employees stick to the new process (you can use workflow management software to help with this. More on that later). Keep track of the process performance. If you find the results unsatisfactory (or believe that there’s room for more improvement), start DMAIC all over again.

To learn more about DMAIC, head over to our guide.

Process improvement templates you can use today

Automation software

The easiest wins you can find in process improvement are through automation.

By using the right software, you can free up your employee time by allowing the software to do the menial work for them.

This makes your employees both happier (no one likes grunt work) and more productive (their time is spent on something that creates more value).

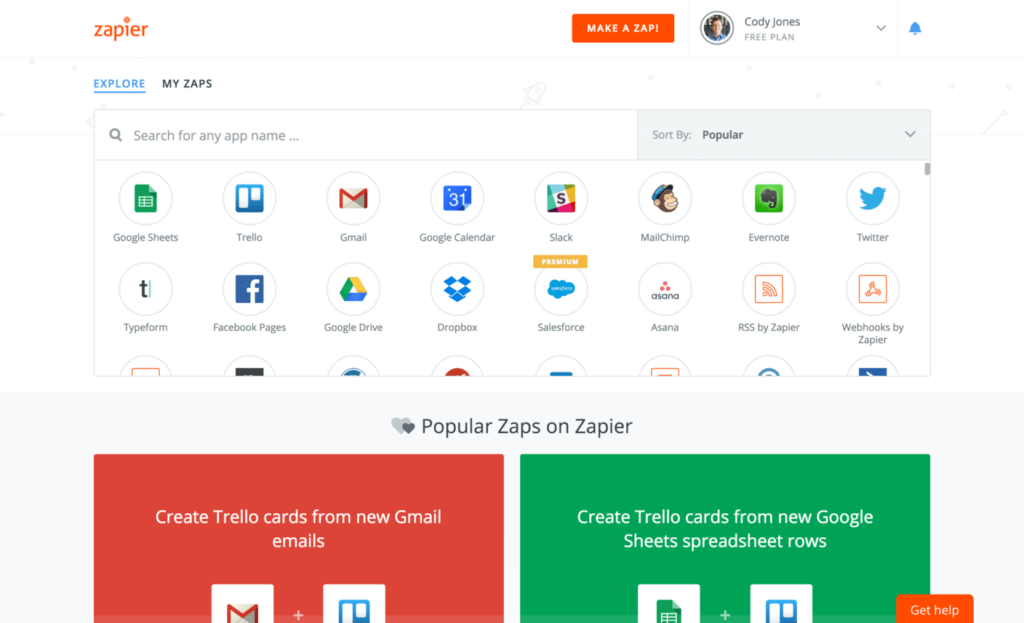

There are 2 types of software that help with automation - task automation software (Zapier) and workflow management software (Tallyfy).

Task automation software

The best (and most popular) software for task automation is Zapier - the software has integrations with most 3rd party tools (Google Suite, and just about anything else).

- 100 tasks/month

- 2-step Zaps only

- 750 tasks/month

- Multi-step Zaps

- 2,000 tasks/month

- Shared workspaces

- SSO

- Custom tasks

- Governance tools

There are a lot of different ways to use Zapier depending on what kind of automation you’re looking for.

For example, let’s say you have an opt-in form on your website that sends the emails to MailChimp.

You also want to feed the same data to your CRM tool so that you can read out to the leads individually.

Instead of having to manually copy and paste the data every time, you can Zap the two tools together, allowing for the data to transfer automatically.

For a complete list of Zapier integrations, you can head over to their website.

To get the most out of task automation tools, you should use them in combination with other software. Learn how with our article.

Workflow management software

A common problem with process management is that you can’t keep track of everyone’s work.

Are your employees following the best practices, or do they tend to deviate?

How do you make sure they stick to the process improvements you’ve made, without having to stand over their shoulder?

Workflow management software helps you enforce business processes.

At Tallyfy, we’ve seen teams struggle for months with spreadsheets and email chains before realizing they need a proper system to track who’s doing what. The system acts as a facilitator for your processes - it lets your employees know whenever they’re assigned a new task, as well as if there are any changes to the process.

Instead of having to manually update your employees about the changes you’ve made to processes, the software automatically gives them the updated tasks.

New to process management? Learn everything there is to know about workflow software with our guide. If you’re stuck between choosing a handful of providers, though, check out our comparison of some of the best workflow management tools on the market.

Getting started with process improvement - how to learn more

Knowing what business process improvement tools to use is only one part of a successful process improvement initiative.

Getting this right isn’t easy.

After all, 70% of all improvement initiatives fail. In discussions with operations teams, the main culprits are poor communication and lack of follow-through.

One trap to avoid: collecting too many tools. Just because a technique exists doesn’t mean you need it. Pick the ones that genuinely fit your situation and master those first. A team that knows process flowcharts and 5 Whys inside-out will outperform a team with superficial knowledge of fifteen different methodologies. The old saying about too many cooks applies here - more tools don’t automatically produce better results.

If you need faster results, consider a Rapid Improvement Event (sometimes called a Kaizen Blitz). You pull a cross-functional team together for a focused week, map the current process on Monday, identify improvements by Wednesday, and implement changes by Friday. It sounds aggressive, but the concentrated focus often accomplishes more than months of committee meetings. The key is picking a bounded problem - don’t try to redesign your entire supply chain in five days.

So to maximize your odds, you need to arm yourself with as much know-how as possible.

A good start is to learn about the best practices of process improvement.

Sure, knowing how to use certain tools is helpful, but you should also know how to implement them.

Head over to our guide on business process improvement to learn more about process improvement, such as…

- How to come up with process improvement ideas

- How to empower your employees to improve processes without managerial supervision

- How to implement improvements and measure their success

- And more!

Related questions

Which tool is used for process improvement?

There are many tools that can aid business process improvement, but one of the most valuable is process mapping software.

These digital tools enable you to visually map out your workflows, allowing you to clearly see where bottlenecks and opportunities for improvement exist.

They’re a bit like a GPS for your business processes, pointing you in the direction of the speedier path to greater efficiency.

What are business process improvement techniques?

Consider business process improvement approaches as a toolbox for repairing your company’s engine.

Popular approaches include the Lean system, which is all about eliminating waste, and Six Sigma, which seeks to minimize errors.

Another technique is the DMAIC, (Define, Measure, Analyze, Improve and Control) model.

It’s a little bit like running through all the tests you’d want to do for your body and then prescribing the right intervention.

What are the key steps used to improve a business process?

Optimizing a business process is no different from renovating a house.

You have to spot the process you’re hoping to improve first.

Then, study it to figure out what works and what doesn’t.

Next, come up with ideas to help mitigate that, and test them.

Finally, make the changes and see the results.

It’s an iterative process, constantly seeking ways to make things run that little bit smoother.

What are the two most used process improvement methods?

There are 2 heavy weight champs in the process improvement world, Lean and Six Sigma.

Lean is about removing waste from processes, streamlining things, just like you would declutter your house to make it more liveable, so that you’ve got space and you’ve got the chance to breathe pretty much.

Six Sigma, in contrast, aims to eliminate errors and variations, much as one would fine-tune an instrument in order to produce the sound one wants to hear.

Most people roll them together into Lean Six Sigma for a high efficiency-high quality one-two punch.

Is Six Sigma a process improvement tool?

Yes, Six Sigma is an approach to process improvement, but it’s a collection of tools rather than a single tool.

It’s an entire methodology that encompasses all kinds of techniques and strategies.

Six Sigma strives to improve quality by identifying and eliminating the root cause of defects and reducing variation in business processes.

It’s like: Everything is a detective and a problem solver and a quality control person in one package.

What are common KPIs for process improvement?

In process improvement, KPIs are specific metrics used to monitor the success of a process.

They’re the indicators that you’re on the right path.

They tend to be common ones like cycle time (how long a process takes), error rate (how often things go wrong), customer satisfaction scores and cost savings.

Employee productivity is also an important KPI.

These measurements allow you to see if your efforts to get better are working — a little like stepping on a scale can tell you if your diet is actually working.

About the Author

Amit is the CEO of Tallyfy. He is a workflow expert and specializes in process automation and the next generation of business process management in the post-flowchart age. He has decades of consulting experience in task and workflow automation, continuous improvement (all the flavors) and AI-driven workflows for small and large companies. Amit did a Computer Science degree at the University of Bath and moved from the UK to St. Louis, MO in 2014. He loves watching American robins and their nesting behaviors!

Follow Amit on his website, LinkedIn, Facebook, Reddit, X (Twitter) or YouTube.

Automate your workflows with Tallyfy

Stop chasing status updates. Track and automate your processes in one place.