More often than not, things don’t really go your way. Your proven processes go awry, the machinery breaks, leading to a metaphorical fire in the company offices. Every other department is running around panicking, trying to figure out what happened.

The thing is, though, even if you manage to solve the problem for that specific issue (think, using duct tape to piece a machine back together, use a fire extinguisher to kill a spontaneous fire, etc.), your work is not really done. Unless you determine the root cause of the problem, as in, what caused it, the problem is bound to arise again.

The 5 Whys method is a popular process improvement and problem-solving technique, allowing you to determine what caused any given problem.

So What’s the 5 Whys Method?

The 5 Whys, as we’ve already mentioned, is a technique used for determining the root cause of any given issue. The gist of it is, whenever something goes wrong, you keep asking “why?” five times until you determine what the problem really is. Below is a practical example to give you a better idea of how this works.

You’re a sales manager in a software company. At the end of Q2, on a meeting with management, you realize that the sales are down significantly compared to the past year (and not hitting the KPIs, to boot). You organize a meeting with the rest of the management team and conduct the 5 Whys analysis…

- Why are the sales down?

- Because the sales team isn’t closing as many leads as before

- Why?

- Because the leads are weaker and significantly harder to sell to

- Why?

- The marketing team has been trying out new lead generation partners

- Why?

- Because the finance department denied working with the old partner

- Why?

- Because the old partner upped their rates by 20%

After finishing the analysis, you already have several different options on how to fix the issue. You could, for example, count the numbers and determine whether the old partner’s new rates are worthwhile for you (higher sales and profits, despite the upped margin). Or, you might want to try new lead generation companies, some of which could be an even better match than the last.

Then, you write down the potential solutions, assign a responsible person for each, and set up a meeting to report back on the findings.

The History of the 5 Whys Technique

The 5 Whys was first developed by Taiichi Ohno, an industrial engineer who is considered to be the father of the Toyota Production System. It is based on the Toyota’s “go and see” philosophy, which focuses on going out on the field and figuring out what really is happening, rather than basing decisions on what the management thinks could be happening.

The 5 Whys analysis method became popular somewhere around the 1970s. Because of its simplicity and potential, however, it’s still being used today a tool in several different process improvement methodologies…

- Kaizen – Toyota’s philosophy of continuous improvement. It’s based on continually analyzing and improving company processes using scientific management

- Business Process Management – Methodology of streamlining, improving and managing company processes

- Six Sigma– A set of tools and techniques used for minimizing waste and defects in business processes

How to do the 5 Whys Analysis

If something goes wrong, first things first – you’ve got to put out all the fires. After the crisis is averted, it’s time to figure why it happened and how to make sure it never happens again.

The step one is to get the ball rolling – invited everyone that’s remotely related to the incident. Usually, this includes the members of a given team (Think, engineering for software crash). Then, you assign the role of facilitator for the meeting. This should either be department head or a specialist most knowledgeable on the issue (Think, CTO vs Cyber Security Expert). As a given, there should also be someone to document the meeting, ensuring that you don’t miss out on some important point.

Then, before you even begin the 5 Whys analysis, you need to pinpoint and formalize the exact problem. If you don’t have a clearly defined goal for the meeting, it might turn out that each of your team members is solving a completely different issue.

Finally, ask away! Keep asking “why?” until you manage to discover at least one possible root cause of the issue. Once you’ve pointed out the problem, assign relevant team members to come up with and apply the solution.

Document and Follow-up

Sometimes, the first solution you come up with might not be the best (or, it might not work at all). It’s important to document the entire process, from brainstorming to problem-solving and let everyone on the team know.

So, once the initial meeting is over, make sure that everyone has the notes and is aware of what the next steps are. The employees that are in charge of solving the problem should also document their work and in case the solution fails, report back.

If the solution isn’t working, or if there’s more than one root cause to the issue, you can always start the whole process all over again, conducting another 5 Whys analysis.

Human Error as the Root Cause

Sometimes, the 5 Whys analysis will determine that the root cause of the problem is some employee’s mistake.

Making sure this kind of mistakes don’t happen can be hard. While you can put out the fires, you can’t ensure that no one will make the same mistake again. It’s all too human to mess up here and there, after all.

What you can do, though, is minimize these chances the best you can.

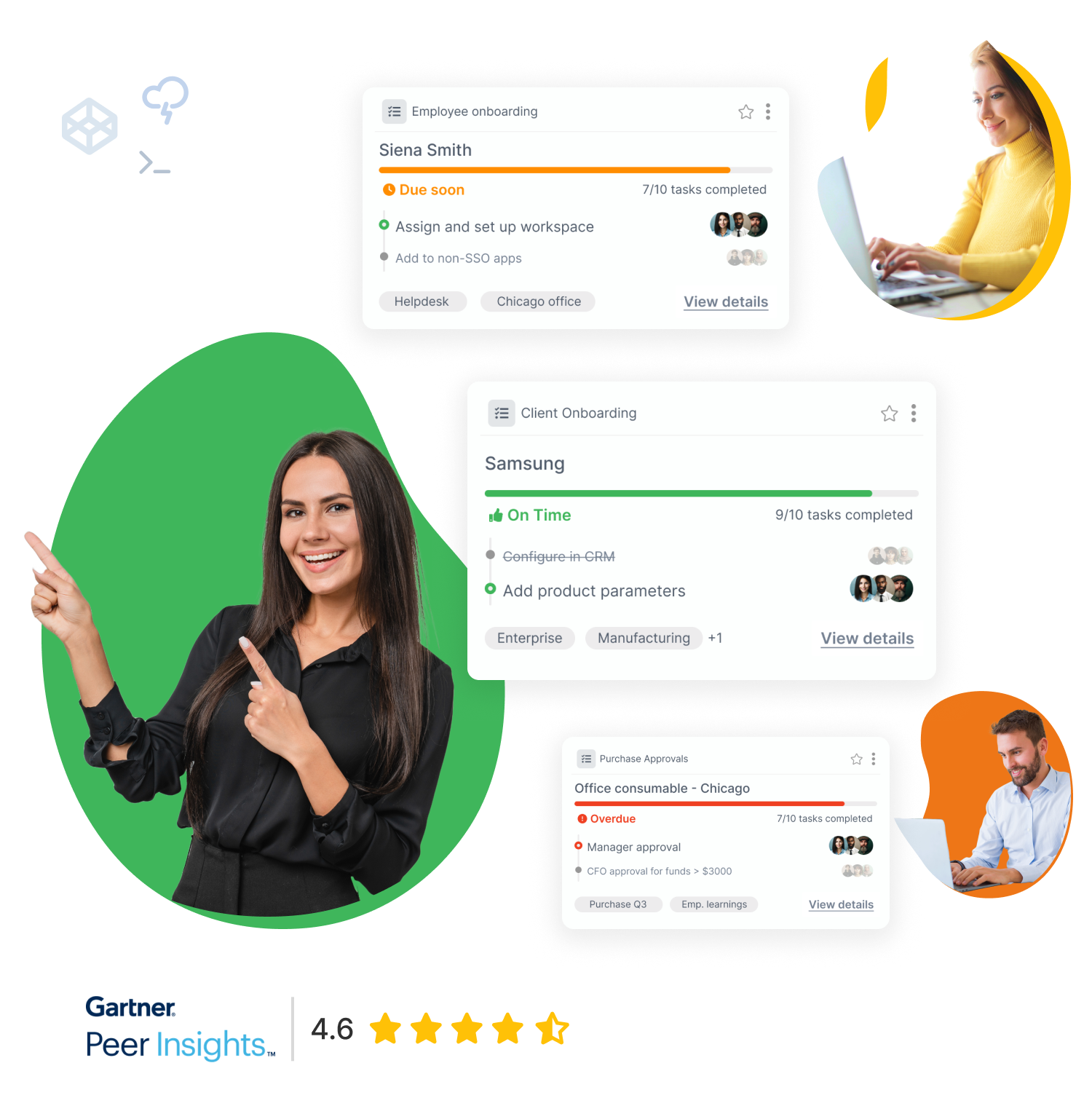

By using Workflow Management Software, you can standardize your processes. This way, your employees will have software looking over their work, ensuring that every step of the way is carried out without mistakes.

Related Questions

What is the root cause of a problem?

By definition, a “root” is the origin of anything – which holds true for the root cause as well. It’s not unlike locating the head of a river — if you follow it back through all the various streams and tributaries you will finally find the source. Not only do they want to find out what went wrong, but also why, which is what set things off in the first place.

What is a root cause example?

Contrast it with a household with a wet floor. The immediate issue, of course, is the wet floor, but you might follow the trail to find that the wet floor is a product of a leaky pipe, which is a result of water that froze, expanded and cracked the pipe, in a house with a bad heating system that failed to keep the pipes warm, and you never bothered to maintain or had repaired until the freeze plunged your home into a state of emergency. The true problem here is not the wet floor, not even the faulty pipe – it’s the absence of schedule for proper maintenance.

What is the root source of the problem?

Root source is the initiator or the beginning of a problem. It’s like…there’s an onion and you can’t just break it down, you have to remove all the layers layer by stupid layer until you get to the fucking centre! We assume so often what we take to be the cause turns out to be just another symptom of an underlying problem lurking beneath.

What are the causes of problems?

Issues usually come from mixed sources: error, systems failures, communication holes, environmental elements or process failures. These causes often twine together like a tree’s roots and nourish one another. Some problems are such that they have multiple root causes that are interlocked or work in unison with each other, therefore, identifying and working with those one at a time is important.

What is a root cause situation?

A root cause situation is when you’re looking at a problem and there’s something you need to get to the bottom of before you can address solutions. It’s like being a detective who has to ignore the obvious evidence to piece together the true narrative. These are the sort of situations that are usually characterised by complicated systems, and happen when tweaks made at the surface will not lead to sustainable solutions.

Why should you identify root causes?

Going to the root cause is important for it avoids the problem recurring. It’s like treating a disease instead of the symptoms, you can help the problem but the issue will still return again and again because you’re not fixing the cause of the problem. Tackling root causes enables permanent solutions and saves you in time and resources in the long run.

How do you distinguish between symptoms and root causes?

Symptoms are akin to a warning icon on your car’s dashboard — it tells you something is wrong, but not exactly what. Root causes are the specific mechanical problems that are creating those warnings. The trick is to ask “why” again and again, five times or more, until you can no longer go any deeper. If you can still ask “why” after reaching a cause, you haven’t gotten to the root.

What tools can help identify root causes?

A number of techniques can help reveal the root cause, from simple strategies, such as the “5 Whys” approach, to more sophisticated tools such as fishbone diagrams and fault tree analysis. Imagine these tools as various kinds of microscopes—the various types help you look at the problem from various angles and at various depths.

How do you prevent root causes from recurring?

Preventing it will involve systemic changes and protections being developed. It’s kind of like this is building a fence around an area that is unsafe – you need to have controls, checks and balances in place so that it is simply harder for the problem to happen again. That might mean overhauling processes, adding monitoring systems or honing training.

What role does data play in root cause analysis?

Data is a flashlight in a dark room, shedding light on patterns and relationships that aren’t necessarily apparent at first. Picking up and putting down information as you collect and analyze it will allow you to see patterns, recognize correlations, and make informed decisions about what’s actually causing you trouble.

How do organizational culture and root causes connect?

Culture is often the ground from which issues are cultivated. Institutional factors: ‘Tensions between beliefs and practices’ Values, beliefs and practices at the level of the organization may or may not encourage or discourage ‘certain types of problems.’ Just as the quality of garden soil affects a plant’s health, culture affects how problems arise and how readily they are resolved.

What makes root cause analysis difficult?

Root cause analysis can be difficult due to the fact that most problems are multi-facetted and interrelated. It’s like a puzzle in which some pieces are hidden and others may look like they fit, but don’t. People may also resist recognizing underlying problems, particularly where sensitive issues are involved or when large changes are needed.