Six Sigma is a framework that was designed to eliminate waste and improve the customer experience. It was introduced to our mainstream business culture in the 1980’s when Bill Smith, an engineer for Motorola, first introduced the concept.

The smart guy will outsmart himself. The lucky guy will run out of luck. The money guy will never have the desire. But hard work will take you anywhere you want to go.Bill Smith

Today, according to many business development experts, Six Sigma is the most popular quality improvement methodology in history. It is used worldwide across a diverse range of organizations including nonprofits, prisons, hospitals, banks, and corporations. The article will look more closely at what Six Sigma is, what the benefits are of using it, and how businesses can successfully implement it.

What is Six Sigma?

So what does it mean to be a Six Sigma organization? If you are running a Six Sigma organization, then for every million opportunities there are no more than 3.4 inefficiencies. In other words, it demands results that are close to perfection.

If this sounds extreme or unrealistic to you then consider the alternatives. If a business was operating at a Three Sigma level, this would mean that for every million opportunities there would be 66,807 defects.

Or to put it another way, if a pharmacy operated at a Three Sigma level this would mean that there would be 54,000 incorrect drug prescriptions every year. At a Six Sigma level, that same pharmacy would have three incorrect drug prescriptions each year.

The ultimate goal is to improve the experience for the customer by eliminating variation. Variation is simply deviating from what the customer expects and it can cause your customers to quickly lose faith in your company. Variation tells your customers that you are inconsistent and don’t deliver predictable results.

DMAIC

Six Sigma is usually accomplished by implementing the basic methodology DMAIC. DMAIC stands for define, measurement, analysis, improvement, and control and it has helped many businesses get rid of waste.

- Design: During this phase, your team will clearly outline what the problem is. You will also decide on a goal and evaluate all the tools and resources available to you.

- Measurement: Next your team will look more closely at the process that is already in place and measure its performance. By evaluating how the process is performing you will have a better idea of what improvement is needed.

- Analysis: When your team analyzes the problem, you will try to discover the root cause of that problem.

- Improvement: Once the problem has been identified, your team is ready to brainstorm possible solutions and put a plan in place.

- Control: This is the final step and it involves creating systems to control the process performance. This is important because, without it, you may just end up dealing with the exact same issue in another six months.

Benefits of Implementing Six Sigma

Organizations from nearly every industry have benefitted from Six Sigma, including companies like Motorola, General Electric, and Honeywell. It can benefit the customer, individual employees, and the company as a whole. Listed below are the five biggest advantages many businesses see as a result of implementing Six Sigma:

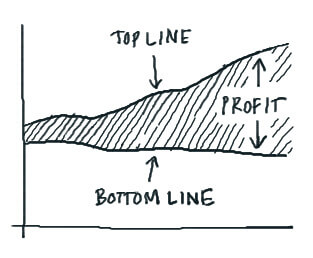

Increased revenue

When your company improves the quality of its services and products you can see incredible long-term revenue increases. After its first year of using Six Sigma principles, General Electric saw $300 million in increased revenue.

Better quality

By operating a Six Sigma business, companies have to minimize defects and improve quality to the point that few customers will ever experience a problem. And this does not just apply to manufactured products; at Akron’s Children’s Hospital, the quality of their services increased tremendously by implementing Six Sigma. The wait times for MRI scans were cut down by 90 percent and the emergency room minimized the amount of time it took to locate supplies by 63 percent.

Reduced costs

Successful Six Sigma implementation can result in massive savings, which will allow your company to use that money elsewhere. In 2007, the United States Army implemented Six Sigma and saved over $2 billion that year by streamlining task management, cutting costs, and recycling fuel.

Improves the customer experience

When you improve the quality of your products and services and reduce variation, your customers will reap the benefits. And when customers receive a consistently positive experience, they are more likely to become loyal long-term customers.

Increased productivity

Often businesses think they are overstaffed when the real problem in insufficient training. Implementing Six Sigma can give your business clarity on the root cause of low productivity and help you effectively address it.

Belt Levels

When your company decides to implement Six Sigma, you will most likely work closely with a professional who will help you implement these changes. These professionals are given various “belt levels” based on their experience, past contributions, and capabilities. Working with a Six Sigma professional is an important component in achieving the success you are hoping for. Here is a list of the belt levels and what each one means:

- Master Black Belts: Master Black Belts are responsible for strategizing and finding ways to apply Six Sigma principles across business structures. They also will usually provide training to other team members.

- Black Belts: Black Belts will also lead projects for businesses that provide solutions to high-level problems. They are also responsible for providing training for team members.

- Green Belts: Green Belts will collect data and provide analysis.

- Yellow Belts: Yellow Belts usually assist the team with process improvements.

- White Belts: White Belts will usually help with solving problems but they are not necessarily a part of the team.

Implementing Six Sigma

Strategies for implementation can vary quite a bit depending on the organization and the specific business goals. However, once a company has decided to implement Six Sigma there are usually two ways to go about this. They can either implement a case-by-case initiative or create a Six Sigma infrastructure.

A case-by-case initiative involves certain employees being taught specific tools that they can apply to jobs as needed. Other employees can consult with that person if they need help on a certain project. This method can result in success but rarely does this strategy result in major changes to the organization.

By creating a Six Sigma infrastructure, you will use it through projects rather than just individual tools. This is often a more focused and productive way to implement Six Sigma tools. It can also lead to a more detailed understanding of important business processes.

Conclusion

Six Sigma can help your business eliminate waste, reduce variation, and improve the customer experience. It isn’t a fad and it isn’t going away anytime soon; it is a proven business method for improving a company’s operations.

But in spite of its many successes, over 60 percent of Six Sigma projects do not achieve the desired results. There are many reasons why this happens, but more often than not, the reason is not being able to enforce the changes you’ve made to the processes.

Process management software, however, can help with that. Tallyfy helps establish & enforce standardized processes, making sure that your business is running at peak efficiency.

Related Questions

What is Six Sigma in simple terms?

Six Sigma is just like a detective story of your business processes; just but different. At its core, it is a methodology for finding variation and defects — the annoyances that make everyone’s lives a little harder. I always thought of that as the difference between a messy kitchen where cookies get randomly burnt or come out raw vs. a super precise operation where each time, every batch is just so perfectly the same. Six Sigma provides tools that can help you reduce errors to only 3.4 errors per million opportunities – which is still mind-blowing to me! It’s about making customers happier, saving your sanity, and increasing your bottom line.

What are the 6 points of Six Sigma?

DMAIC Framework for Six Sigma: The DMAIC framework forms the backbone of Six Sigma – not the best acronym ever, but it gets the job done! It’s the acronym: Define (be crystal clear on the problem to be improved), Measure (collect real data – no conjecture allowed!), Analyze (where you dig down to root causes), Improve (get to your actual solutions that work), Control (a means to make improvements stick). Many practitioners will also include a sixth element – Repeat - because improvement never really stops. Like my ongoing quest for inbox zero, there’s more journey than destination! They flow one to the other, so that there’s an orderly progression toward a more habitual process for overcoming disorder within any system.

What does 6 sigma level mean?

The term “Six Sigma level” describes near-perfection — in fact, 3.4 defects in 1,000,000 opportunities. As a person who sometimes puts my shirt on backward in the morning, I find this level of precision impressive and a little intimidating! If you want to put it into perspective: If your local power utility had only a 3-sigma level of service, you’d be without power for almost 15 hours a day! At Six Sigma, one second of downtime only occurs every 34 days. That staggering difference is precisely what makes Six Sigma relevant to critical processes in every business; just think about how much confidence would you have if you could say daily operations with a Six Sigma level of reliability!

What is Six Sigma and what is its goal?

Six Sigma is basically the problem-solver superhero for business processes! If the Data-Driven Quality Checklist course is not the course for you and you are looking for an in-depth exploration of the skills, tools and techniques to improve quality, look no further than the Data-Driven Quality Handbook course, which many believe will be the handbook for the digital age of quality — packed with statistical tools and methodologies, but its heart beats for excellence through continuous improvement. Its primary goal? And processes that are so reliable that defects are events that occur infrequently. What I like about Six Sigma is that it treats the root cause instead of the symptoms – it’s that doctor that tests you for every possible thing just to find that serious ailment. Originally conceived at Motorola in the 1980s, its principles apply across virtually every type of workflow — manufacturing, marketing, client onboarding, and more.

How is Six Sigma different from other improvement methods?

What sets Six Sigma apart is its uncompromising commitment to data and statistics – it’s for the “show me the evidence” crowd, not the “trust your gut” folks. While Lean focuses primarily on eliminating waste and Agile emphasizes adaptability, Six Sigma is laser-focused on reducing variation and defects. It’s like the difference between saying “this room feels hot” versus using a thermometer to confirm it’s exactly 78.6°F and then systematically figuring out why. This data-driven approach has saved Fortune 500 companies billions – and frankly, it’s hard to argue with those kinds of results!

Who can use Six Sigma?

Here’s a myth I love to blow up: Six Sigma is for more than manufacturing behemoths or deep-pocket companies. These principles are so powerful because they can be applied in many different industries – I have seen them used in healthcare, financial services, education, and even at home to optimize household routines! If you have processes that could be more consistent (and who doesn’t?)Whether you operate a global operation or a local food truck, Six Sigma principles can be useful in this regard. The nuances may be different, but the basic method of getting better is unbelievably powerful across contexts.

What are the levels of Six Sigma certification?

The colored belt system was taken from martial arts, which cracks me up — business analysts breaking boards in their cubicles! The typical progression: White Belt (keenly aware of what’s happening), Yellow Belt (grasp fundamentals), Green Belt (photos and best practices applied to projects), Black Belt (master practitioners leading complex projects) and Master Black Belt (the senseis who go on train others). They also delineate further levels of specialization in statistical methods and problem-solving approaches. What I like about this system is that it establishes a clear path to improvement and a corresponding internal support infrastructure — Green Belts can work on improvements part-time and Black Belts frequently become full-time change agents.

How long does it take to implement Six Sigma?

If there is one bit of advice I would give to new organizations that are embarking on Six Sigma implementation, it is this: patience is a virtue. Which means that to hope for significant results you’ll need a process transformation that typically takes months to a year. And you know what, that’s a good thing! Short solutions seldom resolve root problems. A small team could finish their first improvement project in as little as 3-4 months, but an enterprise-wide rollout can be a multi-year effort. The trick is balancing quick wins (to create momentum) with more in-depth, systematic changes. One thing to keep in mind is that Six Sigma is not a project but a capability you are trying to instill in your organisation DNA.

What are the common challenges in Six Sigma implementation?

Having seen my fair share of improvement initiatives, I can tell you the biggest Six Sigma hurdles rarely involve the technical aspects. The real challenges are human: resistance to change (people get mighty attached to “the way we’ve always done it”), leadership commitment that fades when quick wins don’t materialize, and the struggle to maintain momentum when everyday fires demand attention. Another sneaky obstacle? Data collection – many organizations are shocked to discover they don’t actually measure the things that matter most! The most successful implementations have strong executive sponsorship, clear communication about the “why,” and celebrate small victories along the way.

How does Six Sigma save money?

Six Sigma can have an incredible financial impact. I have seen companies discover they were bleeding money in areas they never even considered! These savings come from reduced waste (materials and time), less rework due to defects, reduced variability leading to more predictable performance, and additional capacity without an expanded workforce. Beyond the dollar savings are harder-to-quantify benefits: happier customers, less-stressed employees, and more capacity to focus on growth rather than putting out fires. The ROI can be significant as many organizations see 3-5x returns on investment on their Six Sigma training and implementation.

How does Tallyfy support Six Sigma initiatives?

We at Tallyfy view our workflow software as a great complimentary solution to Six Sigma programs. In contrast, Six Sigma offers the methodology to address problem processes, while Tallyfy provides the framework to document, standardize and automate the processes made better. Our platform enables you to capture the “before” state (very important in the Measure phase), execute and monitor the new super-improved process, and sustain the gain during the Control phase. Tallyfy contributes to this by offering real-time visibility into how processes are happening and automatically collecting performance data, hundreds of times reduced manual work that the Six Sigma approach required which is not only sufficient and making it easier for you to get results, but also ensures that the changes stay in place, and which has been proven at many Tallyfy customers.

Why is Tallyfy passionate about process improvement methodologies like Six Sigma?

We’re naturally attracted to Six Sigma because we have the same obsession with removing chaos from business processes! Six Sigma’s data-driven techniques to reduce the cause of variation and defects are applied to the utmost end. During Six Sigma, and during Tallyfy, we both know that quality begins with the basis of wrote, standardized that processes. What strikes us particularly is Six Sigma’s focus on measurement, if you don’t measure you can’t improve. This is why we’ve baked in strong tracking into our own platform, so that teams have the data they need to pinpoint issues and prove that fixes are working. Underpinned by these questions we think Tallyfy’s workflow automation can be an extremely powerful addition to the Six Sigma toolbox combining analytical rigor with process/user satisfaction.