In the business world, there has been some debate when it comes to Lean vs Six Sigma. Most people have strong opinions about which method is more effective for cutting costs and eliminating waste. Lean manufacturing is a systematic way of eliminating waste and creating flow in the production process, while Six Sigma is a set of techniques that strive to greatly reduce the rate of defects.

Essentially, Six Sigma and Lean systems have the same goal. They both seek to eliminate waste and create the most efficient system possible, but they take different approaches toward how achieving this goal. In simplest terms, the main difference between Lean and Six Sigma is that they identify the root cause of waste differently.Villanova University

Every business has areas that need improvement and sometimes it can be hard to know where to start. And as the debate over Lean vs Six Sigma continues in the business world you may not be sure if either method is right for your company.

Although many people compare Lean vs Six Sigma, they can often be more powerful when used together. This article will look more closely at the differences between Lean vs Six Sigma and the benefits of both.

The History of Lean Manufacturing

Lean manufacturing is not new, the ideas behind it were originally introduced by Henry Ford. He liked to keep the production standards incredibly high so that each step flowed naturally into the next, thus resulting in very little waste.

Toyota then accommodated this process and developed the Toyota Production System, which became one of the most efficient systems in the world.

The biggest difference between Lean vs Six Sigma is that they view the causes of waste very differently. The ultimate goal of lean manufacturing is to reduce waste by eliminating bottlenecks and improving the quality of your products.

Lean identifies seven areas of waste that are common in most production systems. Let’s look at each of the “seven deadly wastes” in more detail.

The 7 Deadly Wastes

- Overproduction: This occurs when products are being produced that there is no customer demand for.

- Waiting: Waiting is the lag time in between each step in production. When employees are left waiting no value is being added.

- Transport: This type of waste occurs when materials or products are moved inefficiently.

- Motion: Motion refers to poor work standards and employees moving inefficiently between tasks.

- Over-processing: Over-processing occurs when you spend too much time producing a product or produce it in a very inefficient way.

- Inventory: This happens when your inventory levels are too high and you have too much work in progress at one time.

- Defects: Defects are the number of time employees spend identifying and fixing production mistakes.

Implementing Lean will allow employees to move materials less frequently which will improve the quality and require less overall inventory. It also allows quality issues to be dealt with during the manufacturing process, which saves both time and resources because employees aren’t scrambling to fix mistakes later.

All of the improvements listed above will result in a more successful manufacturing process. As the products are being produced and delivered on time, the customers will have a more satisfying experience. And because the products were produced to a higher standard of quality, there will be fewer customer complaints.

The History of Six Sigma

Another main difference in Lean vs Six Sigma is that lean is used primarily in production while Six Sigma can be used to reduce errors in production as well as nonproduction environments.

Six Sigma looks to reduce waste and it defines a defect as anything that doesn’t meet the customer’s expectations. It focuses more on eliminating any variation in the customer experience. A Six Sigma company will produce no more than 3.4 defects for every million opportunities.

Six Sigma was introduced in the 1980’s by an engineer for Motorola named Bill Smith. Smith believed that by getting rid of variation you can improve the customer experience and increase your overall savings.

Six Sigma has helped Motorola save millions of dollars in revenue. After witnessing Motorola’s success, other companies have adopted Six Sigma and seen dramatic savings as well. General Electric, Toshiba, Bank of America, and Intel have all adopted Six Sigma principles and seen dramatic improvements.

DMAIC

One of the main differences between Lean vs Six Sigma is each method implements process improvement. Six Sigma does this primarily by using DMAIC. DMAIC stands for define, measure, analysis, improvement, and control. Here is a more in-depth look at each step of the process:

- Define: In this first step, you will define the problem and how it is affecting the current process.

- Measure: During this step, you will measure the current data. By examining the process that is already in place and identifying what isn’t working you can begin finding ways to make improvements.

- Analysis: Now that you have measured all of your current data, you can begin analyzing it to get to the root of the problem.

- Improvement: This is the step where you will come up with solutions, test your solutions, and make improvements as needed.

- Control: Once you have implemented a new process you must continue to make improvements over time. These changes will only last if employees continue to refine and maintain the process.

Lean vs Six Sigma

Although we are comparing Lean vs Six Sigma, the truth is they both work toward the same ultimate goal: eliminating waste and creating efficient processes. They simply take different approaches on how to accomplish this.

Lean focuses on analyzing workflow to reduce cycle time and eliminate waste. Lean strives to maximize value to the customer while using a few resources as possible. Six Sigma strives for near perfect results that will reduce costs and achieve higher levels of customer satisfaction.

To summarize the main difference between Lean vs Six Sigma, lean looks at ways to increase flow while Six Sigma focuses on achieving consistent results.

One similarity between Lean vs Six Sigma is that both have demonstrated that it is possible to dramatically improve the quality of your products and customer experience by improving processes. And as this article points out, when most companies set out to improve inefficient processes they feel like must choose only one method going forward.

Ultimately, the issue may not be whether you should choose Lean vs Six Sigma but how you can take the elements you like from each and apply them to solve problems in your own business.

Conclusion

We often hear about the exciting transformations businesses have seen using with either Lean or Six Sigma. However, the reality is that most companies that adopt either will fail. 60 percent of all Six Sigma projects fail and 40-60 percent of lean projects fail to achieve the desired results. Why does this happen?

Whenever a new Lean or Six Sigma project is started there is always an initial wave of momentum and excitement. But over time, most businesses simply don’t have the ability to sustain the changes made from and often they revert back to the former inefficient processes they had when they started.

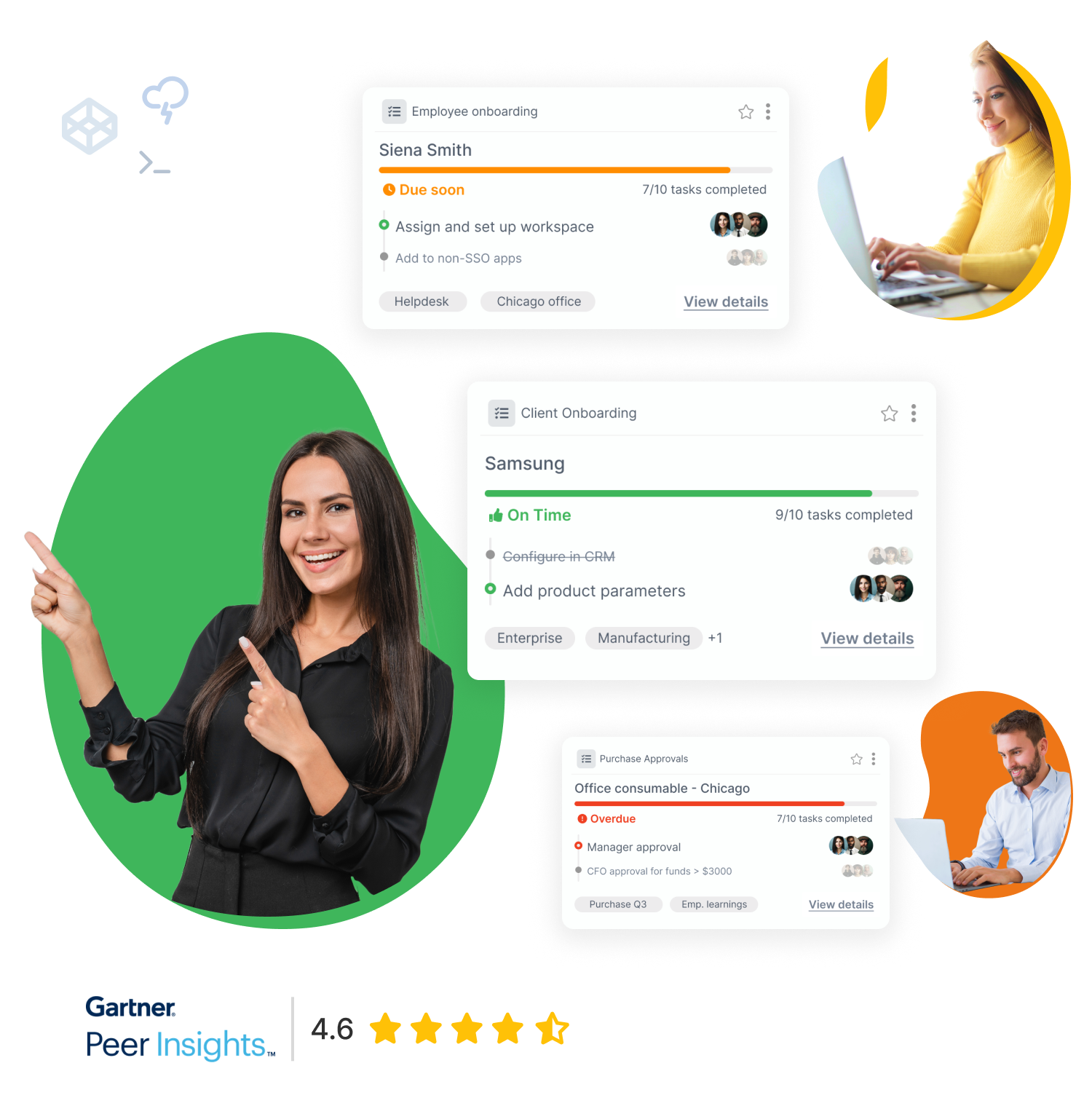

Using the right process tracking software, however, can significantly increase your chances of success. Tallyfy’s Business Process Management Software allows you to create digital processes which you can track, automate and improve.

And the best part? It’s free to use for up to 5 users.

Related Questions

What is the difference between Six Sigma and Lean?

Six Sigma and Lean, while both want to develop the best possible business process, they simply have different priorities. 6 Sigma focuses on the elimination of variation and defects, and uses data and statistics to solve problems. Lean, by contrast, is about eliminating waste and unnecessary steps from a process so that more value is created with less input. Think of 6 Sigma as a precision guided missile for quality control, where Lean is a decluttering consultant for your operations.

Should I do Lean or Six Sigma first?

The answer isn’t one-size-fits-all, but many experts recommend starting with Lean. Why? Lean emphasizes waste reduction and flow improvement; it can make itself visible in no time, improving team esprit de corps and buy-in. It’s like cleaning your room before organizing it — you clear away the clutter first, then fine-tune. After you’ve “leaned out” your processes, 6 Sigma can help you with more challenging, data-driven improvements.

Is Lean Six Sigma outdated?

Far from it! Though Lean Six Sigma is years old, it’s more important now than in it’s ever been in today’s fast-paced, efficiency-based world. However, it’s evolving. Lean Six Sigma has evolved to Lean Six Sigma 4.0, which includes new technologies (like AI and machine learning), applies to both digital processes and services (not just manufacturing) and has a higher focus on the customer than before. It’s sort of like a classic car that’s been outfitted with a hybrid engine — same dependable frame, but with some fresher-baked amenities.

What is the difference between Kaizen and Lean Six Sigma?

Kaizen and Lean Six Sigma are essentially cousins in the improvement family. Kaizen, which is a Japanese word that means “continuous improvement,” is also a lifestyle of making small changes every day. It’s as if you just keep straightening your desk over time.” Lean Six Sigma on the other hand is a more structured method that joins Lean waste reduction with Six Sigma defect elimination. It frequently includes bigger, project-based improvements. If you wanted to explain it to someone you might say that Kaizen is like the daily vitamin and Lean Six Sigma is more like an intensive workout regimen.

Should I do Lean or Six Sigma first?

This question is so good, I want to answer it twice! Now let’s look at it in reverse. The decision between Lean and Six Sigma will depend on your organization’s current situation first. If you are up to your eyeballs in waste and inefficiencies, Lean may be your life preserver. It’s like the clearing of a path in a cluttered room. But if you’re experiencing quality problems or customer complaints and everything seems to be running smoothly, Six Sigma may just be the right first step for you. It’s another form of tuning a good-looking engine but not running well. Remember the most pressing thing here is improvement, so drive your initial focus toward whatever approach solves the most problems for you.