Traditionally, lean business processes were centered in the manufacturing sector as a means of controlling cost. This ensures that the production process or it’s costs don’t have an impact on the forecasted bottom line. But there’s nothing that limits the growing SaaS industry, or any other industry, from taking a lean business approach to developing hyper-effective processes and profitable business models.

To be competitive, we have to look for every opportunity to improve efficiencies and productivity while increasing quality. Lean manufacturing principles have improved every aspect of our processes.Cynthia Fanning

To develop lean business processes, the general procedure is managing processes, auditing from point to point, and improving those processes through the compression of time rather than trying to juggle and manage assets.

If you view every business as a collection of processes designed to complete tasks, create value (for the company and the customer) with secondary processes to support the others (the office and administration for example) you can see how it applies to virtually every business.

What is Lean Process Improvement

In most cases, lean process improvement emphasizes not only the prevention of waste but the elimination of existing waste. Rather than adding processes, or trying to manage existing processes, you have to first reduce waste.

That means targeting time, labor and materials that are not being used effectively or are wasted.

For a manufacturing business, that could be reducing material variances. A SaaS company could be faced with bloated hours due to hiring too many developers or developer overtime on extended services that are unnecessary.

Some businesses develop leaner processes to better serve their customers while still cutting costs. For example, a manufacturer of snowboards improves customization options for their product to delight customers. Rather than build excess inventory they make products to order. This reduces inventory overhead and eliminates the need for constant production.

Goals of Lean Business Processes

The primary goal of lean business processes is to reduce wasteful spending. This kind of spending can happen in countless ways given how different every business can be.

To reach that reduction in spending, businesses should set one or more of the following goals:

Improve Quality

The quality of your goods or services directly impacts your ability to meet or exceed customer expectations. Let’s say a product you sell has parts that can be sourced from 3 different suppliers. The cost varies with each, as does the quality. The cheapest option can save you hundreds of thousands each quarter but is more prone to defect.

While you save during production, the likelihood of greater defects is going to impact the customer experience. That results in bad reviews, negative PR, and diminishing returns. Sometimes cheap isn’t so cheap.

Lean business processes allow you to focus on quality on the front end. This cuts the costs of your product in the long run and increases the lifetime value of your customers.

Likewise, improved quality in production reduces the need for frequent quality control checks. You can put those man hours into customer service or reduce your workforce accordingly.

Eliminate Waste

Companies tend to account for waste and activity at every stage as part of their overhead – costs which get rolled into the price paid by customers. There isn’t a customer alive that wants to pay for your organizations waste and inability to control your costs.

Thus, an essential step in creating lean business processes is eliminating wasteful activities that eat up time and resources but provide no value to you or the customer.

Reduce Lead Time

Lead times are the gaps between steps in a process or the amount of time it takes to complete a series of tasks. Lead times are one of the greatest areas of waste within a company that can and should be controlled through process improvement.

Long lead times can undermine your business by interrupting critical processes. A few examples of lead time problems:

- The amount of time it takes to receive or send a payment after receipt of a sales order or purchase order

- The lead time for turning raw materials into a finished product

- The launch time, from point to point, once a product or service is ready to roll out

- The lead time in the execution of a marketing campaign from the point of ideation

Reduce Total Cost

Your total cost is made up of the direct and indirect costs of getting your product to customers or selling and delivering your service to customers. There’s never a fixed cost involved, and those costs can and will fluctuate.

Because of this fluctuation, you have to continually balance the prices of your product/service against operating costs. Finding ways to reduce cost through lean processes can help you retain market share and prevent your profit margin from shrinking.

The Key Areas of Waste

Waste is anything that provides no value to the customer, contributes nothing to your bottom line, but absolutely has a cost. It exists at every level of your company, in every department, and within virtually every activity that takes place.

When you can transition your teams away from a “that’s just how we do it” mentality, you can start developing lean business processes by identifying and eliminating key areas of waste.

The ultimate lean target is the total elimination of waste. And while that is virtually impossible to achieve, it should still be the ultimate goal. Here are the most common areas of waste in business, regardless of sector or industry.

Inventory

For product-based businesses, inventory can be a massive waste. This is especially true in the CPG industry where products can expire. Any inventory that isn’t directly required for meeting customer orders should be considered potential waste.

Examine your inventory against sales data to reduce inventory to the absolute minimum. Reset production processes so you’re only producing the inventory necessary to meet short-term sales. If you’re able to do so, transform your production process so that you’re producing based on customer demand rather than maintaining inventory overhead.

Inventory isn’t just applicable to your products. You have to consider your office supplies and what you regularly keep in stock for the administrative side of your business. If you spend money on office supplies, then you have wasted money sitting in unneeded files, supplies, extra copies, books and manuals, shipping supplies, and more.

Overproduction

For manufacturing, this ties back to your inventory. Companies often want to keep employees busy so their labor is well-used, they’ll continue production, and move more stock into the warehouse. The better approach is to reduce hours and trim those employees when the work is done.

In times like this you’re wasting on the product and the cost of maintaining that inventory as well as the labor involved in creating and maintaining that product.

Overproduction also occurs in the office and in service related businesses. For example, developers producing too many features beyond what is necessary (working out of scope), workers pulling reports before they’re needed, or over-analyzing data. It boils down to employees producing beyond the scope of what is expected or required.

Multistep approval processes in production with lean batching, and cutting labor hours accordingly, can help reduce wasteful production that doesn’t produce an immediate return.

Over-processing

It’s staggering how many companies utilize an extensive system of checks and balances to catch errors, yet they still occur. Where we aim for improving quality on the output, we wind up wasting more without making a significant dent to justify the costs.

Over-processing often occurs when extra work is required to fix issues and defects, or to rework a problem that could have been done properly the first time if processes were carefully followed and/or improved upon.

One of the largest wastes in this regard is how many times a piece of paperwork will change hands. In one corporate position I held, any expense invoices would require four different signatures and two approval stamps from different departments before expenses would be reimbursed. Each time I had to turn in expenses (which was roughly every 2 week pay period due to travel) I was forced to interrupt those employees.

If I didn’t interrupt their activity and simply left the expense report, the lead time to completion would go from 1 day to more than a week.

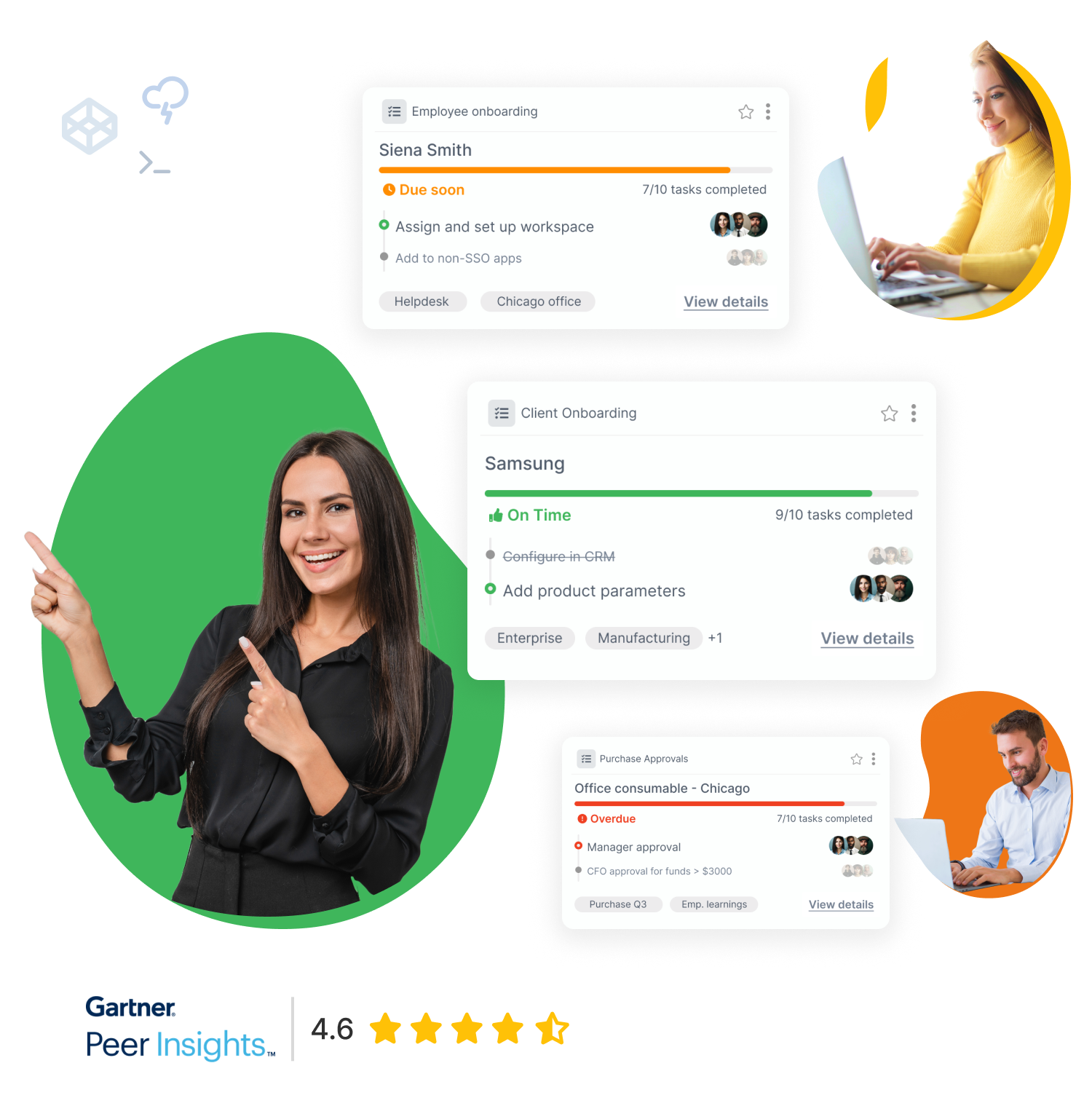

This is when automated approval processes for document sorting and filing can streamline many of the problems that plague the office environment. Requiring an approval, and holding teams accountable for those approvals can get documents sorted quickly while keeping lead times down. It can also eliminate over processing in virtually any environment since each step requires an approval and review.

This improves accountability, reduces errors, reduces the number of people who need to be involved, and ensures that nothing is missed.

Transportation

It’s shocking how much cost goes into moving something, be it product or data. For manufacturing and physical goods, products are constantly moved from one facility to another despite the fact that they may sit for an extended period. In many cases, they’re constantly routed around the same facility to make room for additional inventory being moved.

Products get routed further than necessary and transportation for filing, stocking, stacking and moving continues to eat up labor and fuel costs. Sometimes this transportation isn’t authorized and employees move product randomly. There’s an immediate cost to that, plus additional costs when other team members have to spend additional time locating the original products that should have never been moved.

For offices that utilize multiple systems without business process integration, a tremendous amount of waste occurs when the same data has to be entered multiple times across different platforms.

Integrated software applications, automated processes, and leaner operations can eliminate a great deal of this waste.

Downtime

Downtime occurs regularly, often as a period of forced inactivity due to a downstream process that is halted or bottlenecked. Waiting for parts and subcomponents, change in orders, downed equipment, too-frequent inspections, product changes, a lack of orders and more can all bring manufacturing to a halt.

With family in the automotive industry, I frequently hear about temporary layoffs with changeovers for new vehicles and production that can last as long as 7 weeks.

This same delay occurs in the office environment as well. Marketing departments, accounting, and others may find themselves without work to do when they’re stuck waiting for feedback, approvals or decisions from leadership.

Clearly defined, lean process can eliminate some downtime in production and manufacturing. For the office environment, approval processes with notifications can ensure that decisions and approvals are turned around quickly.

Building Lean Business Processes

To create lean business processes, you’ll have to audit and reorganize them. Those processes must also be more effective and help you achieve your goals.

Before that can take place you have to reduce waste. A costly process with a lot of waste can be streamlined but it’s still going to produce waste. If you eliminate the cause of the waste first, you’ll be building processes around the optimal performance of your departments and teams.

We try to keep our content fresh and up-to-date. If you have a suggestion on how to improve this post, please leave a comment below.