Value Stream Mapping: Definition, Steps and Examples

Value stream mapping is a tool you can use when looking at ways to implement lean manufacturing principles. Find out how to make and use value stream maps.

Value stream mapping identifies waste in end-to-end processes.

Tallyfy is Process Improvement Made Easy

Summary

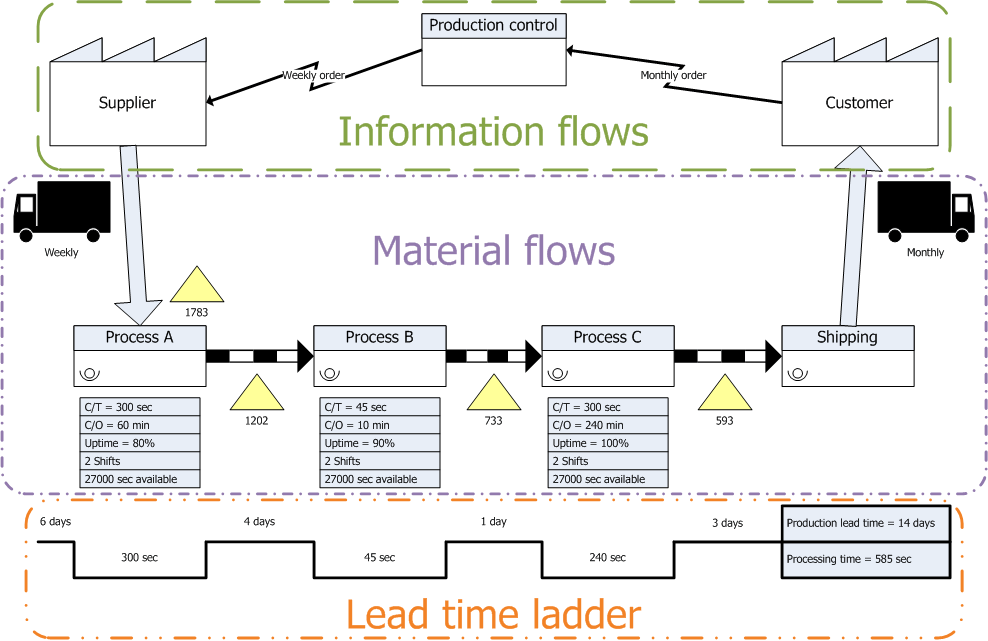

- VSM visualizes your entire production flow - Maps every step from raw material delivery to customer delivery, including both value-adding processes (sowing, growing, grading) and non-value-adding steps (transport, waiting), plus all information flows between departments

- Identifies three critical problems - Helps spot delays that hold up processes, restraints that limit throughput, and excess inventory that ties up resources unproductively, originally designed for manufacturing but works for any industry

- 7-step systematic approach - Define start and end points, map all process steps, trace information flows, gather data on cycle times and inventory levels, add timelines showing lead time versus actual work time, identify the seven wastes, then create an ideal future state map

- Seven wastes drain your profits - Transport (moving materials), Inventory (capital tied up), Motion (wasted movement), Waiting (bottlenecks), Over-processing (unnecessary steps), Overproduction (making too much), and Defects (rework costs). See how Tallyfy helps eliminate process waste

Value stream mapping is a lean management tool that helps visualize the steps needed to take from product creation to delivering it to the end-customer. As with other business process mapping methods, it helps with introspection (understanding your business better), as well as analysis and process improvement.

Source: wikipedia

The inputs for a values stream map include all the resources you use to produce goods or services. The route you follow consists of value adding steps, as well as their attendant non-value-adding steps. And your map will also follow information flows.

Want a more in-depth explanation on what value stream mapping is? Check out our video: What is Value Stream Mapping?

How to use a value stream map

As we have already mentioned, a value stream map allows you to see a top-down overview of your business processes. Then, you can analyze the process or workflow, identifying wastes and inefficiencies. Typically, here are a couple of things you would want to be on the lookout for:

- Delays that hold up the process

- Restraints that limit the process

- Excess inventory that ties up resources unproductively

While value stream mapping is usually used for manufacturing processes, the same principles can apply to other industries too.

What you need to get started

First up, you need to decide what you want to map. In some businesses, one value stream map can cover just about everything the company does. This works well if your company produces a single product.

If you have a complex mix of products or services, though, then you’d have to draw a separate map for each. With which process you would start is, of course, up to you. Generally, though, you would want to start off with the highest value areas.

To actually carry out the mapping, you would want to gather a small project team consisting of representatives from different departments. From what I’ve seen facilitating these sessions, team members have a first-hand perspective on how things are done, and how well the current system works. They know the real problems. One operations manager told us their VSM exercise revealed a 3-day wait time between quality inspection and shipping that nobody had noticed because it fell between two departments.

Workflow automation is at the core of what we discuss with organizations at Tallyfy. In our experience helping organizations map their value streams, this cross-functional approach reveals bottlenecks that no single department could identify alone.

You might even figure out several ways to improve the processes without even consulting the value stream map. Next up, you need a facilitator. This could be a senior manager who understands value stream mapping, or you can get an external consultant to help you.

As you work, you will create your map - but be ready to make changes as you go. Someone may just remember a missed step somewhere along the line, and that can change the whole picture.

To actually draw the map, you can use:

- Pen & Paper - the simplest solution, just grab an A3 paper & a pencil and get to work.

- Flowchart Software - dedicated tools used for all sorts of business process mapping.

- Workflow Management Software - custom solutions for managing company workflows. In addition to simple mapping capabilities, you can also keep track of and manage the workflows.

Value stream mapping symbols

Symbols help with your visual overview. They show exactly what kind of step you are dealing with. While you could always come up with your own symbols, it is usually easier to find an already established style and stick with it.

The symbols are usually pretty intuitive - a simple line drawing of a pair of spectacles, for example, indicates that someone has to “go and see,” while a truck indicates transport.

7 steps to value stream mapping

Now that you know the basics of value stream mapping, here are the exact steps you would need to take to carry out the initiative…

Decide how far you want to go

Typically, you would start your mapping by indicating a start and end point. This would show where your internal process begins and ends. Some companies, however, prefer to map out the entire value chain. This, of course, has its pros and cons - while it does give you a better idea of the whole process, there is usually not much you can do about any external processes.

Your average value stream map begins with the delivery of materials from direct suppliers and ends with delivery to the customer. Place the icon you have chosen to represent your starting and ending points on the left and right of your map.

If your production processes are complex, you might decide to map each of the value-adding processes in greater detail after completing your overall map. In this case, you would start with the process that allocates the work as “supplier” and the process that receives it as the “client.”

Define the steps

Now determine what processes are involved in order to get from point A to point B.

As a simple example, a nursery producing ornamental plants begins with seed from a supplier and delivers plants to a customer. Intervening steps that add value along the way might include:

- Sowing

- Transplanting

- Growing

- Grading

- Shipping

Indicate the information flows

One of the advantages of value stream mapping is that it includes information flows. To continue with the example above, our plant nursery needs to place orders for its suppliers and its customers will place orders for delivery. How often is this done and how? Record it on your map.

The teams or individuals responsible for each process that takes the product from input to output also need information. Where does it come from and how is this information passed on? Perhaps our flower grower has a centralized planning department which receives sales information and places orders with the seed supplier. It then uses this info and provides a weekly or monthly schedule for each of the processes.

Add this department in the middle of the sheet between the input and output blocks, draw another block below it to indicate the weekly plan, and draw arrows from the plan to each of the departments it informs.

Gather the critical data

You now have the basics, and it’s time for an in-depth look at each process. To do so, you need real data and some of your mapping team might have to spend a little time collecting the information you need. Typical points to look at would include:

- The inventory items held for each process

- The cycle time (typically per unit)

- The transfer time

- The number of people needed to perform each step

- A number of products that must be scrapped

- The pack or pallet size that will be used

- The overall batch size that each step handles

Add data and time lines to the map

Once you have all the information, you can start adding it to your map. This is probably the most tedious part. Draw a table or data box under each process block to do so. If you have used historical data, be sure to verify it using the current inputs and outputs for each process.

Indicate the timeline involved in each process beneath your data blocks. This shows the lead time needed to produce products and the actual time spent on producing each unit, pack size, or batch. Don’t be surprised if a product with a lead time of weeks takes just a few hours to produce.

Identify the seven wastes of lean

Just creating a value stream map without using it would be a complete waste of time. Now that you have one, it is time to start looking for the “seven wastes” that could be eating up your profits.

- Transport does not add value to your final product - unless you are in the transport business! See if you can reduce steps involving transport of materials or information that do not add value.

- Inventory of inputs and finished products costs you money which could have been earning income elsewhere. The lower your inventory levels can be without stonewalling production, the better it will be.

- Motion costs time and time is money. As an example, our nursery worker has to move her transplanted seedling 10 feet from the potting table to the tractor wagon. That is wasted time.

- Waiting because there is a bottleneck in a previous process or sub-process is another clear waste of valuable resources.

- Over-processing can be hard to gauge, but if an item can move from one process to another in an acceptable condition with less input, it should do so.

- Overproduction is an additional pitfall to avoid. Even if your product is not perishable, storing it and monitoring it until such time as a customer buys it is clearly a waste.

- Defects mean reworking or scrapping and are clear money-eaters. How can you reduce defects in each step of the process you have mapped?

Create the ideal value stream map

You know how things are if you maintain the status quo, but how would you like them to look? Use your team to help you map out an ideal value stream map that eliminates, or at least reduces, all the wastes you spotted when analyzing the results of your value stream mapping exercise.

It’s unlikely you’ll be able to get there in one step, so you can create a series of intermediate future state maps. In our experience helping teams implement lean improvements, organizations that aim to reach these milestones at specific dates ultimately reach the goal they identified when drawing up their ideal state map.

What should you do now? Start the mapping process all over again! Few processes are so perfect that there is no more room for improvement! Your aim is nothing less than operational excellence.

Do you see the waste?

Are you hearing this at work? That's busywork

Enter between 1 and 150,000

Enter between 0.5 and 40

Enter between $10 and $1,000

Based on $30/hr x 4 hrs/wk

Your loss and waste is:

every week

What you are losing

Cash burned on busywork

per week in wasted wages

What you could have gained

160 extra hours could create:

per week in real and compounding value

Total cumulative impact over time (real cost + missed opportunities)

You are bleeding cash, annoying every employee and killing dreams.

It's a no-brainer

Conclusion

The one drawback of value stream mapping done the old-fashioned way is the time that elapses between report-backs and meetings. For those hoping to slim down process flows fast, this can be frustrating.

There’s also the matter of monitoring the effects of changes you’ve decided to implement. Unforeseen, and possibly unwanted, consequences can flow from new parameters - or people could simply be getting it wrong because they are not used to the new work method yet.

The best way to fix that and speed things up is adopting the right technology. Tallyfy is a workflow management tool that can help you with process mapping and data gathering. It can also help enforce your new processes. Why not give the free demonstration a try?

Workflow templates for value stream mapping

About the Author

Amit is the CEO of Tallyfy. He is a workflow expert and specializes in process automation and the next generation of business process management in the post-flowchart age. He has decades of consulting experience in task and workflow automation, continuous improvement (all the flavors) and AI-driven workflows for small and large companies. Amit did a Computer Science degree at the University of Bath and moved from the UK to St. Louis, MO in 2014. He loves watching American robins and their nesting behaviors!

Follow Amit on his website, LinkedIn, Facebook, Reddit, X (Twitter) or YouTube.

Automate your workflows with Tallyfy

Stop chasing status updates. Track and automate your processes in one place.