In every business, there is always at least one area that could be improved. But how exactly does meaningful change take place within an organization?

Sometimes it can occur through a

major initiative or total upheaval within the business. But most of the time, change happens in a

much less overt way; it happens slowly and more gradually over time. Operational excellence is an example of this type of change.

In this guide, we will look more closely at what operational excellence is, its

10 core principles, as well as the

different methodologies you can use to implement it.

What is Operational Excellence?

Operational excellence can simply be described as a

philosophy that embraces problem-solving and leadership as the key to continuous improvement.

People are often unsure of how to approach the subject of operational excellence. It is a

difficult term to define and most people either find the topic to be too

ambiguous or too

broad to talk about.

Operational excellence, however, is

not a set of activities that you perform. It’s more of a

mindset that should be present within you and your employees.

Now, you’re probably thinking, “that sounds nice

in theory, but how do I translate this into actionable steps?”

Well, we’re going to explain that

in a bit. Before we get into implementing operational excellence, you need to understand how the concept is related to

continuous improvement.

Operational Excellence vs Continuous Improvement

Continuous improvement is the on-going effort to improve an organization’s

processes, products, or services. It usually takes place

incrementally over time, rather than instantly through some breakthrough innovation.

By pursuing continuous improvement, an organization has a greater likelihood of continuing to maintain and build on these improvements.

However, while continuous improvement is important, it is not enough on its own. As the organization continues to refine its process, product, or service, it needs

a way to continue to grow. This is where operational excellence comes in.

Operational excellence is a mindset that embraces certain principles and tools to create sustainable improvement within an organization.

Or to put it more simply, operational excellence is achieved when every member of an organization can see the

flow of value to the customer. Seeing it, however, isn’t enough – they should actively try to improve

both the value, as well as its delivery.

Ultimately, operational excellence is not just about reducing costs or increasing productivity in the workplace. It’s about creating the company culture that will allow you to produce valuable products and services for your customers and achieve

long-term sustainable growth.

Operational excellence is a journey that involves applying the right tools to the right processes. When this happens successfully, the ideal work culture is created where employees are provided for in a way that enables them to stay

empowered and

motivated.

Operational Excellence: 10 Core Principles

Every year, the Shingo Institute of the Jon M. Huntsman School of Business gives out an award for operational excellence called the Shingo Prize. This prize is based on company culture, company results, and how well every employee demonstrates the Guiding Principles of

the Shingo Model. Here is a more in-depth look at each of those ten principles…

Principle #1: Respect Every Individual

The Shingo Model emphasizes that because everyone has worth and potential, everyone deserves respect. However, it’s not enough to have respect for others; you must demonstrate this respect to them as well.

One of the best ways to demonstrate respect for your employees is by

involving them in any necessary improvements to their department. This will help them feel more empowered and motivated to contribute to the changes in a positive way.

To learn more about how to create a culture that engages every employee, from CEO to shop-floor staff, read our guide to Kaizen.Principle #2: Lead with Humility

Leaders should always exercise humility.

After all, the best improvements happen people can acknowledge their shortcomings and look for a better solution. Humility involves a willingness to listen and take suggestions from everyone, regardless of that person’s position or status within the company.

Principle #3: Seek perfection

This step in the model is often met with resistance as most people are quick to point out that perfection isn’t possible. While perfection may feel unattainable that doesn’t mean you can’t

strive for it anyway.

By setting the bar high, you create a different mindset within your organization. When confronted with a problem, try to

look for long-term solutions and always try to

simplify your work without compromising the quality of the outcome.

Principle #4: Embrace Scientific Thinking

Innovation comes from

constant experimentation and learning.

Hence, it’s always useful to know what works and what doesn’t. By systematically exploring new ideas you can encourage employees to do the same without fear of failure.

Principle #5: Focus on the Process

When things go wrong, there is a tendency to want to blame other people. In a lot of cases, however, problem is rooted in the process, not the person. This is because even

great employees can’t consistently produce ideal results with a

bad process.

When a mistake occurs, rather than immediately pointing fingers at the employees involved, assess what part of the process the error occurred in. Once you have done this you can make adjustments to try to

achieve the results you want.

Principle #6: Assure Quality at the Source

High quality can only be achieved once

every part of the process is done correctly. It can be helpful to organize work areas in a way that will allow potential problems to become visible right away. When a mistake does occur, stop working immediately to correct the mistake before continuing.

Principle #7: Flow and Pull Value

The object of every organization is to provide maximum value to its customers. Because of this, organizations should ensure that the process and

workflow are continuous because interruptions create

waste and inefficiencies.

It is also important to evaluate customer demands to ensure that your organization is only meeting those demands and not creating more than what is necessary.

Principle #8: Think Systematically

In a system, there are many different interconnected parts that work together. It is important to understand the relationship between each of these parts because it will help you make better decisions. You should avoid taking on a narrow vision of your organization and get rid of any barriers that interrupt the flow of ideas and information.

Principle #9: Create Constancy of Purpose

Employees should be informed of the goals and mission statement of the organization from

day one. This shouldn’t just stop after day one, however. You should continue to emphasize these goals and principles every day going forward.

Every employee should have an

unwavering certainty of why the organization exists, where it’s going, and how it will get there. Knowing this will help them align their own actions and goals with those of the company.

Principle #10: Create Value for the Customer

To create value for the customer you have to understand

what the customer needs. The value is simply what that person is willing to pay for.

Organizations must continue to work to understand the needs and expectations of their customers. An organization that stops delivering value to the customer is not sustainable over time.

Top 3 Operational Excellence Methodologies

Through

operational excellence, an organization can improve its

company culture and performance, which leads to

long-term sustainable growth.

Businesses should consider looking past the traditional one-time event and move toward a more long-term system for change.

Over the years,

numerous methodologies have been introduced to the mainstream business culture as a method of achieving operational excellence. We will look more 3 of the most popular ones below…

Methodology #1: Lean Manufacturing

Lean manufacturing focuses on systematically eliminating waste in a production system.

It teaches that the only thing a business should focus on is that which

adds value. Lean also teaches that every process has some sort of

bottleneck and that focusing all your improvement efforts on that bottleneck is the quickest path to success.

The key principles of lean manufacturing focus on

improving the quality of products and services, eliminating anything that doesn’t add value, and reducing overall costs.

Traditional lean manufacturing identifies seven areas of waste which are commonly referred to as the “

seven deadly wastes.” Specifically, these are…

- Overproduction: Overproduction happens when employees produce something before it is actually needed. This is one of the worst forms of waste because it leads to excessive inventory and often masks underlying problems.

- Waiting: When employees are left waiting for the next step in production no value is being added. It can be very eye-opening to examine each step from the beginning to the end and then evaluate how much time is actually being spent adding value and how much time is spent waiting.

- Transport: Transport is waste caused by unnecessary movement of uncompleted or finished products.

- Motion: This step refers to all movement that doesn’t add any value to the product and is usually caused by poor work standards.

- Over-processing: This happens when more time is spent on processing than is necessary to produce what the customer needs. It is also one of the hardest wastes to get rid of.

- Inventory: This type of waste occurs when the supply exceeds what the actual demands are.

- Defects: Defects are mistakes that will either need to be fixed or the process will have to start over entirely. In manufacturing, this usually looks like a part that either has to be scrapped or completely remade.

Methodology #2: Six Sigma

Six Sigma is a set of

tools and techniques that are designed to improve business processes which will result in a better product or service. The goal of Six Sigma is to improve the

customer experience by identifying and eliminating variation.

Over 50 percent of all Fortune 500 companies have implemented Six Sigma to some degree. It has been shown that Six Sigma has helped Fortune 500 companies save over $427 billion over the past 20 years.

A Six Sigma business will produce no more than 3.4 defects for every million opportunities. A defect is defined as anything that fails to meet the customer’s expectations. It does this primarily by implementing

DMAIC.

DMAIC is an acronym that stands for define, measure, analysis, improvement, and control. Here is a closer look at each step in this process and how it helps to build Six Sigma businesses:

- Define: In this first step, you will simply define the problem because without knowing what the problem is, you really can’t fix it. Once you have defined the problem you can begin creating a plan and evaluating your available resources.

- Measure: Now that you understand the problem, you need to measure all of your available data and look closely at your current process. What is working well and what needs to be improved?

- Analysis: Once you have measured your data, you can analyze your findings and get to the root of the problem.

- Improvement: After you analyze your data, begin coming up with possible solutions. Implement these solutions on a small scale to test the results so you can make any necessary changes.

- Control: Once you have implemented your new process you need to find a way to maintain that process. Continuous improvement is important to ensure that your process stays effective.

Methodology #3: Kaizen

Kaizen means “

continuous improvement” in Japanese and in business, it used to implement positive, ongoing changes in the workplace.

The guiding principles of Kaizen are that a good process will lead to positive results, teamwork is crucial to success, and that any process can be improved.

Organizations implement kaizen to help them create a culture of continuous improvement. Employees will work together to achieve ongoing workplace improvements.

Kaizen teaches that when applied consistently, small changes will compound over time and produce big results. The methodology does not necessarily encourage only making small changes, though; kaizen focuses on the participation of all employees to effect real change.

Kaizen stresses the importance of continuous improvement and that it is not enough to make a change once and hope it sticks. You must continue to make improvements repeatedly. Many businesses have used Kaizen to help them increase employee productivity, cut costs, and improve the customer experience.

Achieving Operational Excellence

Operational excellence is the ultimate goal of all organizations striving for continuous improvement. Projects and tools are a useful place to start but on their own, they are not enough to create lasting change.

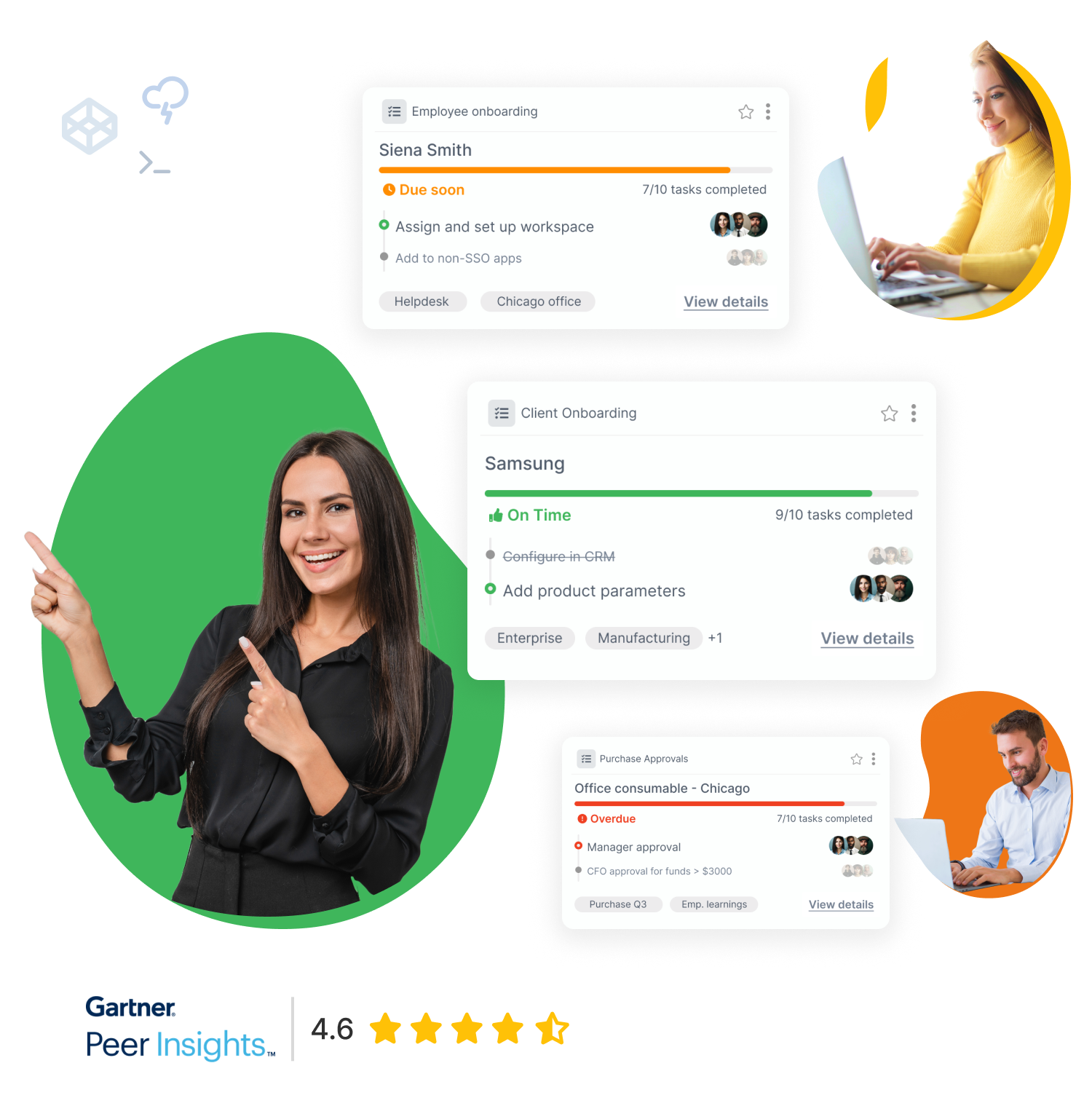

People often think that buying legacy BPM software is a great answer to running operations well. Nothing could be further from the truth.

“Old BPM” software is tired and broken. It never worked for business users. Here’s why:

- Users are now deciding to buy software themselves. Old BPM was bought by your IT department, who didn’t generally care about user experience – as long as it was made by a large/boring company.

- Cloud tools are now free to try by anyone, anytime. With Old BPM you had to call sales and wait for 50 questions just to look at it and finally decide it sucks.

- People want to share workflows with clients. With Old BPM you were stuck with trying to automate internal processes only. Your clients would be very scared and run a mile from it.

- People expect to integrate cloud tools without IT. With Old BPM you had get engineers to write code to make a simple integration. That’s now become a drag-and-drop service.

- People expect to work on phones. This means giant, clunky flowcharts in Old BPM are dead – because they don’t fit on your phone’s screen – and only define “the perfect process”.

- People are tired of flowcharts. Old BPM was all about the high priest telling you how a process can/will be done, and you would obey. Now – modern workers and teams are paid to collaborate.

- People expect all the benefits of the cloud. Old BPM was never cloud-born and was never designed for the cloud. And that creates a massive bunch of missed opportunities.

- Companies of all sizes need process management – and never had it. Since Old BPM was so expensive and complicated, only large companies could afford it. The rest of us were left out.

- People are excited about AI – but confused about where to begin. With Old BPM you have zero chance of using AI without an army of engineers. With cloud-born systems like Tallyfy – it’s childs’ play to use any AI you like to run amazing automations for photos, voice, video and more.

The above reasons are why we built

Tallyfy – the only software that anyone can understand in 60 seconds. Start your journey in operational excellence by picking a platform people will really love.

Lasting change can only happen when the principles of operational excellence are understood and deeply rooted in the culture of an organization.

So, make sure that both the management and the company employees understand & follow the core principles of operational excellence.

Related Questions

What is meant by operational excellence?

Operational excellence is a mindset where everyone in an organization consistently delivers great results in the simplest possible way. Think of it like a well-oiled machine where everything just works smoothly – no waste, no confusion, and everyone knows exactly what they need to do. It’s about making things better every single day, not just once in a while.

What are the 4 pillars of operational excellence?

The four main pillars are people, process, technology, and culture. Picture them like legs of a table – you need all four to be strong. People need the right skills and training, processes must be clear and efficient, technology should make work easier (not harder), and the culture needs to support continuous improvement where everyone feels they can speak up with ideas.

What are the four stages of operational excellence?

The journey to operational excellence moves through four key stages: stabilize (getting basic control), standardize (creating consistent ways of working), optimize (making things better), and innovate (creating breakthrough improvements). It’s like learning to play an instrument – first you learn the basics, then you practice consistently, then you get really good, and finally you can create your own music.

Which best describes operational excellence?

Operational excellence is best described as doing the right things, the right way, every time – even when nobody’s watching. Imagine a restaurant kitchen where every dish comes out perfect, the team works like a symphony, and customers always leave happy. That’s operational excellence in action.

How is operational excellence different from continuous improvement?

While they’re close cousins, operational excellence is the overall destination, while continuous improvement is the journey to get there. Think of continuous improvement as the daily exercise routine, while operational excellence is the peak fitness level you’re trying to achieve. They work together, but they’re not exactly the same thing.

Can small businesses achieve operational excellence?

Absolutely! Small businesses can often achieve operational excellence more easily than large corporations because they’re more nimble and can make changes faster. It’s like turning a speedboat versus a cruise ship – both can reach the destination, but the smaller vessel can adjust course more quickly.

What role does leadership play in operational excellence?

Leaders are like gardeners in operational excellence – they create the right environment for things to grow. They need to set clear expectations, remove obstacles, provide resources, and most importantly, walk the talk. Without good leadership, operational excellence initiatives often wither like plants without water.

How do you measure operational excellence?

Operational excellence is measured through a mix of hard numbers (like productivity, quality, and cost) and soft metrics (like employee satisfaction and customer happiness). It’s similar to measuring your health – you look at both concrete numbers like blood pressure and subjective factors like how you feel.

Why do operational excellence programs fail?

Most programs fail because organizations treat them like a sprint instead of a marathon. Common pitfalls include not getting everyone involved, focusing too much on tools instead of people, and expecting quick fixes. It’s like trying to get fit by buying expensive gym equipment but never changing your daily habits.

What’s the connection between operational excellence and customer satisfaction?

Operational excellence directly impacts customer satisfaction because it eliminates the bumps in the road that frustrate customers. When operations run smoothly behind the scenes, customers get consistent, high-quality experiences. It’s like a duck swimming – the customer sees the smooth movement above water, not the furious paddling underneath.

How does technology support operational excellence?

Technology acts like a powerful magnifying glass for operational excellence – it helps spot problems faster, automates repetitive tasks, and provides data for better decisions. But it’s important to remember that technology is a tool, not a solution. It’s like having a great set of kitchen knives – they make cooking easier but don’t automatically make you a chef.

What’s the role of standardization in operational excellence?

Standardization provides the foundation for operational excellence by creating clear, repeatable ways of working. Think of it like a recipe – once you have the basic steps written down, you can start improving them. Without standardization, you’re just guessing what works and what doesn’t.

How long does it take to achieve operational excellence?

Operational excellence is more of a journey than a destination – organizations can always get better. Most companies start seeing meaningful improvements within 1-2 years, but creating a true culture of excellence takes 3-5 years or more. It’s like learning a new language – you can have basic conversations pretty quickly, but becoming fluent takes time and practice.