What is a process map?

Process maps visually depict how inputs become outputs through workflow steps. They help understand processes, train employees, identify bottlenecks, and eliminate duplication. High-level maps show core processes while low-level maps detail specific tasks, creating clear accountability and improving efficiency throughout your organization.

Process maps transform complex workflows into clear visual documentation. Here is how Tallyfy turns static diagrams into active, trackable processes.

Tallyfy is the only product available that does Process Documentation and Process Tracking in one

Summary

- Visual representation unlocks process understanding - Process maps help train employees faster, identify bottlenecks and duplication, eliminate gaps causing operational problems, and capture workflows so they follow consistent patterns with minimal variation

- Three map types serve different purposes - High-level maps show core processes and departmental flows, low-level maps detail specific tasks within departments, and cross-functional “swim lanes” maps reveal how different functions collaborate on sub-processes

- Maps need discipline to stay useful - Processes constantly evolve with tweaks and changes; if you don’t update maps when changes are implemented, they quickly become outdated and worse than useless. Need help mapping and tracking your processes?

Processes turn inputs into outputs. A process map visually depicts the workflow that achieves this.

The advice I like to give young artists, or really anybody who will listen to me, is not to wait around for inspiration. Inspiration is for amateurs; the rest of us just show up and get to work. If you wait around for the clouds to part and a bolt of lightning to strike you in the brain, you are not going to make an awful lot of work. All the best ideas come out of the process; they come out of the work itself.

— Chuck Close

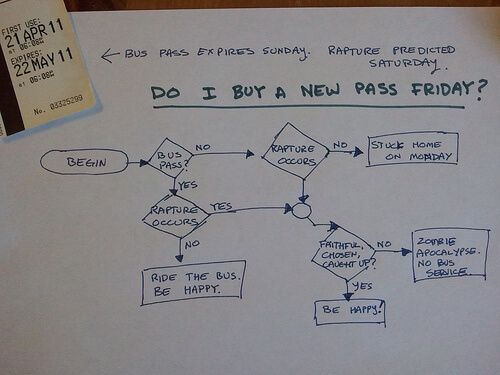

If you’re thinking “That’s just like a process flowchart!” you’ve hit the nail on the head, because the two terms are used to describe the exact same thing. But there are several types of process map, and these are worth examining more closely.

Depicting process flows

There’s more than one way of depicting process flows on a process map. As you will know, there will be conditional points where what happens next depends on the result of the previous step. So you can end up with a muddle of arrows that is hard to follow. Clarity matters here. One of the first principles to bear in mind when designing a process map is that it should be uncluttered and easy to follow.

Naturally, that doesn’t mean you should alter an efficient process just so that it looks better on paper, but it does affect how you will lay out your visual representation.

You can also simplify things by using different shapes of text boxes to indicate just what kind of activity is represented. So, you could place core steps in vertical rectangle text boxes, indicate decisions with a diamond shaped one, and note data transfer steps in horizontal rectangles. These shapes are standardized in Unified Modelling Language (UCL), but there’s nothing stopping you from reinventing the wheel if you prefer other shapes.

Why create a process map in the first place?

Unless your business is tackling something new, you may wonder how creating a process map of existing workflows would be of any use to you. At Tallyfy, we have seen that simply drawing out a process reveals gaps nobody knew existed. One digital strategy consulting firm told us that by forcing themselves to write out the processes, they could now ensure that steps are not missed or done out of order - resulting in fewer mistakes overall. Here are several reasons why a process map could be very helpful indeed:

- Understand the process better yourself.

- Be able to communicate the process to others and train new employees with greater ease.

- Indicate responsibilities and communication channels.

- Capture the process so that it will always follow the same pattern with minimal variation.

- Indicate points in the workflow that should be examined for opportunities to improve.

- Identify bottlenecks that are holding up processes.

- Eliminate duplication of work.

- Identify gaps that are leading to operational problems.

By simply creating a visual representation of processes, we are able to understand them a whole lot better. We can see how different tasks that are performed to obtain desired outputs relate to each other from start to finish, and we are much more easily able to see any lurking problems that need attention to improve efficiency.

When we are looking at creating new workflows, process maps are even more useful. We know what we want to achieve, but we need to identify the exact workflow we will implement before we begin. Thus, process maps are both a planning tool and a way of evaluating and improving existing process flows.

The high-level process map vs low-level process map

In any business, there are workflows and workflows within workflows. For example, you can produce a high-level process map that indicates workflows between departments and core processes, but you can’t possibly include every tiny detail of the work that will be done in each of the departments. If you tried to do so, your process map would become very hard to follow!

To get some order from the chaos, it’s best to begin with the high-level process map. This simply names the core processes, the inputs, and the outputs.

It also shows how they relate to the supplier and the customer. You can use different colors to indicate the type of flow. For example, it’s standard practice to use a red line for primary material flows; a black one for inventory flows, and a dotted line for information flows.

Once you have the high-level process map, it now becomes much easier to deal with the details in low-level process maps.

Here’s a simple example. On your process map, you have flow lines going from the sales team to accounts and from accounts to the customer. There are many other departments with roles, including purchasing, production, and dispatch. But what is the accounts department actually doing?

Zeroing in, you see that in the flow between salespeople and customers, the accounts team has to set up accounts and issue invoices, receipts, and credit notes. It will probably also have to follow up overdue accounts and send out monthly statements.

Now that you have thought this through, you can see that each of these tasks is, in fact, a process. Using the inputs through process actions to final output logic, you can now set up low-level process flows for each of these.

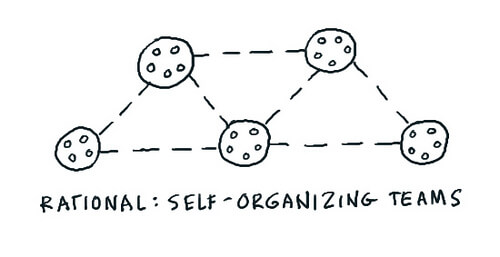

Cross-functional process map

Once you have high and low-level process maps, you might think your work is done, but what about the ways in which different departments or functional areas work together to get a single sub-process done? For this, you might want to consider a cross-functional process map.

In this map, you will create a number of horizontal levels indicating which function performs each task and how the process flows from one function to the next. It looks a bit like the lanes in a swimming pool, so some people call it a “swim lanes” process map. We have seen manufacturing and service companies map processes with 20+ steps flowing through customer service, estimating, operations, material control, and installation - and the cross-functional view instantly reveals where handoffs break down.

Developing process map discipline

It’s easy to see that process maps provide a great way to capture all the procedures involved in getting business done and that doing so can have decided benefits. The problem is that processes aren’t static. Every now and then, you will implement a tweak. If you don’t capture it on your process flow maps, they will soon be outdated and as good as, or worse than, useless.

Thus, if you hope to use process maps and get the full benefits they confer, you will have to be very disciplined about capturing changes as and when they are implemented. In my experience working with teams on process documentation - one of the top three topics in our customer conversations - this discipline separates successful implementations from failed ones.

Calculate your process mapping ROI

You’ve seen how process maps help identify bottlenecks, eliminate duplication, and create clear accountability throughout your organization. From what I’ve seen across our mid-market (55%) and enterprise (45%) customer base, most teams underestimate the gains here. Quantify the potential time and cost savings from proper process visualization.

Are you hearing this at work? That's busywork

Enter between 1 and 150,000

Enter between 0.5 and 40

Enter between $10 and $1,000

Based on $30/hr x 4 hrs/wk

Your loss and waste is:

every week

What you are losing

Cash burned on busywork

per week in wasted wages

What you could have gained

160 extra hours could create:

per week in real and compounding value

Total cumulative impact over time (real cost + missed opportunities)

You are bleeding cash, annoying every employee and killing dreams.

It's a no-brainer

Tallyfy makes it easy

Imagine if you could have a process flow engine that could not only capture and update your process maps but even allocate work as processes move along. Well, you can stop dreaming, because you really can do both of these things with Tallyfy. What’s more, you can use its analytics to determine whether your processes really are working as effectively as you thought they would when you drew up the workflow diagram.

Need a tweak? There’s no need to start from scratch. Just enter your changes along with any conditional logic that determines which route the task should follow based on circumstances, and you’re all set. With each person having his or her own dashboard indicating what to do next, you don’t have to worry about dropped balls or confusion as to what to do and what follows.

About the Author

Amit is the CEO of Tallyfy. He is a workflow expert and specializes in process automation and the next generation of business process management in the post-flowchart age. He has decades of consulting experience in task and workflow automation, continuous improvement (all the flavors) and AI-driven workflows for small and large companies. Amit did a Computer Science degree at the University of Bath and moved from the UK to St. Louis, MO in 2014. He loves watching American robins and their nesting behaviors!

Follow Amit on his website, LinkedIn, Facebook, Reddit, X (Twitter) or YouTube.

Automate your workflows with Tallyfy

Stop chasing status updates. Track and automate your processes in one place.