How PDCA Cycle Can Improve Process Efficiency

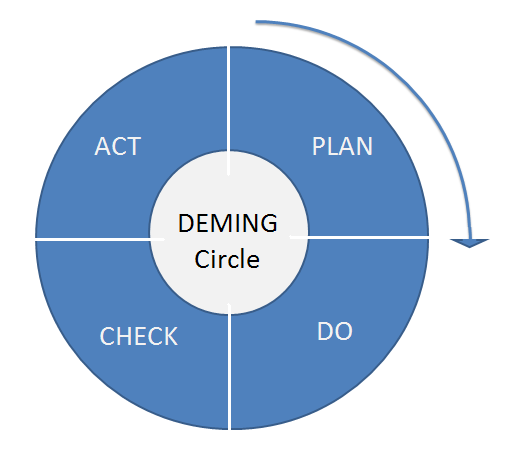

PDCA (Plan-Do-Check-Act), also known as the Deming cycle, is a four-step loop used for achieving continuous process improvement. PDCA involves coming up with process improvement ideas, testing them and implementing them across the organization.

The PDCA cycle is foundational for continuous improvement. Here is how we approach process improvement software.

Tallyfy is Process Improvement Made Easy

Summary

- 5 Whys analysis uncovers root causes systematically - Dr. Deming’s PDCA framework uses iterative questioning to drill down from surface symptoms (sales are down) to root causes (partner raised rates 15%), preventing solutions that address symptoms instead of underlying problems

- Small-scale implementation minimizes risk - The “Do” phase requires testing solutions on a single team, department, or manufacturing site rather than company-wide, because you can’t know for certain whether your fix will be successful until you have empirical data

- Critical checking prevents short-term solutions masking long-term problems - New processes might increase product output at first glance, but deeper analysis could reveal significantly higher defect rates that bring you back to square one, requiring return to the Plan phase for better options

- Continuous feedback loop drives ongoing improvement - PDCA is not a one-time fix but a methodology for continuous process improvement where you establish how processes operate as-is, figure out improvements, implement changes, then repeat the cycle. Need help with process improvement?

The PDCA (Plan-Do-Check-Act), also known as the Deming cycle, is an essential technique for process improvement. Having applied this framework repeatedly while building Tallyfy - and seeing it discussed in many customer conversations - I can tell you it’s a framework that helps you change and improve your processes.

What is the PDCA?

PDCA is a methodology for achieving continuous process improvement. It’s essentially a feedback loop of improvement - you establish how the process operates as-is, figure out how to improve it, and finally, implement the changes.

The concept was first developed by Dr. Williams Edwards Deming, a management consultant, in the 1950s. PDCA consists of 4 phases…

- Plan - Identify what the problem is and analyze it. Find process inefficiencies. Develop potential solutions.

- Do - Implement the solution on a small scale (for minimized risk).

- Check - Benchmark your new process to the old. Is it more efficient? Were you right about the problem / solution? If the solution is less than satisfactory, go back to the “plan” phase and come up with better options.

- Act - If the solution was helpful, implement it company-wide.

PDCA, as a framework, can be extremely helpful if combined with just about any process improvement methodology. There are 2 common use-cases for PDCA:

PDCA, as a framework, can be extremely helpful if combined with just about any process improvement methodology. There are 2 common use-cases for PDCA:

Problem-Solving - Whenever something breaks down or is not functioning as it should be.

PDCA can be used as an analysis tool for uncovering the issue and coming up with a solution. Process Improvement - The fact that something is “working” does not mean it is functioning the best it could be. You can use PDCA as a means of finding potential improvements to existing processes.

The 4 phases of PDCA cycle

To help you use PDCA for your organization, let’s go deeper into each of the steps and explain the exact steps you’ll need to take.

Plan

Before you can make any change to the process, you need to pinpoint the exact issues you will be addressing. If there is an explicit problem you are trying to solve, you could use something like the 5 Whys analysis to find it. The gist of the methodology is, you keep asking “why” until you uncover the root cause of any problem. So for example…

- Why are the sales down?

- Because the sales team are underperforming

- Why?

- The new leads are uninterested and cold

- Why?

- The marketing department started working with new affiliate lead generation partners

- Why?

- The finance department rejected the tender from the older partner

- Why?

- The partner company raised their rates by 15%

Once you know what the root cause of the problem is, you can start coming up with solutions. In this case, if the company revenue is taking a significant hit, it might be a good idea to switch back to the old partner (despite the rates). Or, the company could always look for new potential partners.

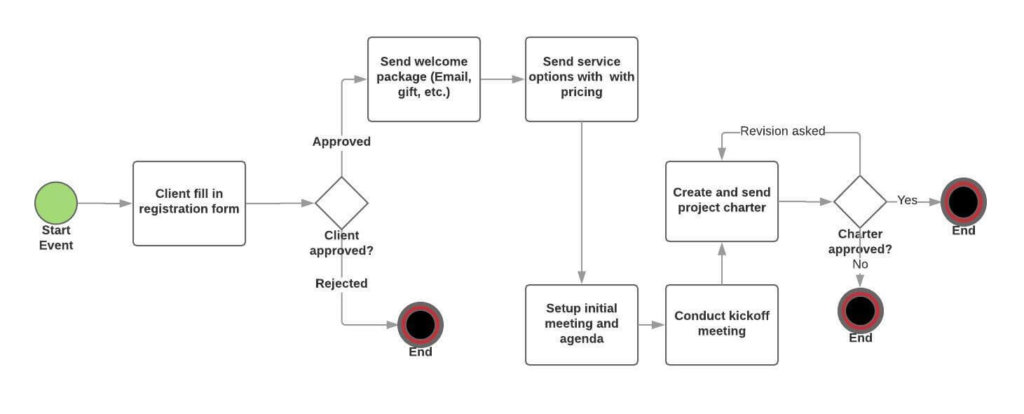

If the process is working as it should and you are simply looking to improve it, you should consider process mapping instead. For this, you will need to figure out how the process works as-is and then create a flowchart diagram. As an example, the following is a client onboarding flowchart…

You can use the diagram to pinpoint inefficiencies within the process and come up with improvement ideas.

👉 Not sure how, exactly, you could improve the business process? The diagrams not helping too much? These 4+ methods might help.

Do

Once you have found the right solution to a problem or a new way to optimize a process, you can start the implementation.

This should, however, be on a small-scale. You can’t know for sure whether your fix is going to be successful, and running it company-wide can be extremely risky. Start small. In discussions we have had about process improvement with consulting firms, we consistently hear that the biggest mistake is rolling out changes company-wide before validating them on a pilot team. One digital strategy consulting firm we spoke with started running all their internal processes manually and on an ad-hoc basis - when they finally standardized, they began with just their client onboarding workflow before expanding to business development and contract approvals. The “small-scale” depends on what the process is. More often than not, though, this means a single team, department, or a manufacturing site (as opposed to the whole plant).

Check

Now that you have empirical data on how well your new process works, you can benchmark it to the old.

It’s crucial to be very critical of this part, though. At Tallyfy, we’ve seen teams celebrate early wins only to discover hidden problems weeks later. At a glance, your solution might be working as planned. But you might discover later that it only works in the short-term.

For example, with your new process, you might be able to increase product output. While this sounds amazing at first, you might later realize that the new process also has a significantly higher defect rate, bringing you all the way back to square one.

So, unless you are 100% certain that the solution you are using is the best option, you might want to consider other possibilities. If you are not, you can always start all over from the “Plan” phase. Once you have found the best potential solution, you can move on to the final phase.

Act

You can finally start applying the solution company-wide. You should consider, though, that PDCA is a loop, not a one-time initiative.

While your process is functioning better now, you can’t really know if that’s the best it can be. Feedback we have received from operations teams suggests that the PDCA cycle works best when you commit to running through it multiple times - one software company we observed reduced a 50-step customer onboarding workflow over several iterations, discovering at each pass which steps could be combined or eliminated entirely. Maybe you will discover a better way of carrying out a certain process step? Or, some new software could help automate the process?

Your new process has now become the baseline, which you should always try to improve. You can repeat the PDCA process as many times as needed until you are certain that the process is as efficient as it can be.

About the Author

Amit is the CEO of Tallyfy. He is a workflow expert and specializes in process automation and the next generation of business process management in the post-flowchart age. He has decades of consulting experience in task and workflow automation, continuous improvement (all the flavors) and AI-driven workflows for small and large companies. Amit did a Computer Science degree at the University of Bath and moved from the UK to St. Louis, MO in 2014. He loves watching American robins and their nesting behaviors!

Follow Amit on his website, LinkedIn, Facebook, Reddit, X (Twitter) or YouTube.

Automate your workflows with Tallyfy

Stop chasing status updates. Track and automate your processes in one place.