Process improvement methodologies - complete list [6+ tools]

Process improvement methodologies help businesses operate efficiently despite fifty to seventy percent of initiatives failing. This complete guide covers Six Sigma tools like DMAIC, Lean Manufacturing waste elimination, and Business Process Management lifecycle for continuous improvement and competitive advantage.

Process improvement requires the right tools to make changes stick. Here is how we approach process improvement.

Tallyfy is Process Improvement Made Easy

Summary

- 50-70% of process improvement initiatives fail - Most fail due to lack of senior management support, poor employee buy-in, or failure to build a culture of continuous improvement, making methodology selection critical

- Six Sigma focuses on eliminating defects - Uses tools like DMAIC (Define, Measure, Analyze, Improve, Control) and 5 Whys Analysis to achieve near-zero defect rates (3.4 defects per million opportunities)

- Lean Manufacturing targets waste elimination - Identifies and removes 7 types of waste (overproduction, waiting, transport, motion, over-processing, inventory, defects) using frameworks like PDCA and Kaizen

- BPM creates continuous improvement cycles - The BPM lifecycle (Analyze, Redesign, Execute, Monitor, Optimize) runs repeatedly on processes, with software ensuring changes actually stick. Need help improving your processes?

To stay competitive in your industry, it’s essential to constantly analyze & improve your business processes. This allows your business to operate as efficiently as possible, minimizing your expenses and maximizing profits.

Process improvement, however, is not all that easy. Around 50% to 70% of all initiatives end up failing.

This can be for a variety of reasons. In my experience helping organizations with process improvements - and process improvement is one of the most discussed topics in our customer conversations across financial services, healthcare, professional services, and manufacturing - the most common include:

- Not getting support from senior management

- Failure to get employee buy-in

- Failing to adopt a culture of continuous improvement

- And many more.

To make sure your initiative is not just another number in that statistic, you can use some of the tried-and-tested process improvement methodologies.

Process improvement methodologies - complete guide

There are a lot of different ways to approach process improvement.

In this guide, we’re going to explain 3 of the most well-known process improvement methodologies - Six Sigma, Lean Manufacturing, and Business Process Management - and arm you with the right tools to get started with each approach.

Six Sigma

Six Sigma is one of the most popular process improvement methodologies out there.

It’s essentially a set of tools and techniques that help your organization with process improvement. The main goal of this methodology is minimizing defect rates and variability in business processes.

For a process to be “Six Sigma,” it has to have almost non-existent defects (3.4 defects out of 1 million opportunities).

Since Six Sigma is mostly about using the right tools, let’s cover some of the most popular ones.

We’re only covering a handful of tools in this guide. To get the complete list, check out our guide to Six Sigma tools.

DMAIC

DMAIC (Define, Measure, Analysis, Improvement, and Control) is a tool that helps with process improvement. Whenever you are working on any given process, you can use it as a framework.

DMAIC is divided into 5 steps. Here is what each of them means…

- Define - Define what, exactly, is the problem and how is it affecting the company. Then, use the aforementioned information to define the goal of the process improvement initiative.

- Measure - This is the stage where you collect all the relevant data. You need to find empirical proof that the existing process is not working, which you will later use as a benchmark for any improvements.

- Analysis - Find the possible causes for the inefficiency of the process. You can use several other Six Sigma tools to help you with this, such as the Fishbone Diagram.

- Improve - Now that you know what the problem with your process is, you can start coming up with solutions. Brainstorm with your team and determine which ones might work. Once you have a couple of ideas, you can move on to the last step.

- Control - Before implementing the process improvement company-wide, you’ve got to make sure that it works as intended.

Give it a couple of trial-runs and benchmark the new data to the old collected in the “measure” stage.

Want to learn more? Check out our primer to DMAIC!

5 Whys analysis

Before you can make improve any given process, you’ve got to figure out what’s wrong with it. What is the root cause of the inefficiency, and how can you fix it?

The 5 Whys is a very straightforward (but useful) methodology for determining the root cause behind any issue. All you have to do is keep asking “why” until you have found what the issue is.

To conduct the analysis, first, you need to figure out what is the issue you are trying to solve. Let’s say, for example, you’re head of sales at a SaaS company & your team isn’t hitting the KPIs.

You need to conduct a meeting with the rest of the management team and carry out the 5 Whys analysis…

- Why are the sales down?

- Because the sales team is not closing as much as they used to

- Why?

- Because a big chunk of the leads are cold & uninterested

- Why?

- Because they are sourced by a different company

- Why?

- Because the finance department rejected working with the original company

- Why?

- Because they raised their rates by 20%

At this point, you have discovered the root cause of the issue (Partner company raising their prices). Now, you can figure out how to deal with it.

You could, for example…

- Decide to work with the original partner company again (if that leads to higher profits even with the price change)

- Try out other lead generation partners

And done! You have your solution to the problem.

You can use the 5 Whys analysis for all sorts of problem-solving - it can even come in hand in your personal life. Check out our article to learn more about the tool!

Lean Manufacturing

Lean Manufacturing is a process improvement methodology that aims to maximize company output by eliminating bottlenecks and improving product quality.

This is done by eliminating 7 types of company waste (also known as 7 Deadly Wastes). Here is what each of them means…

- Overproduction - Creating too much product when there is no real demand for it.

- Waiting - When there is too much time between steps in production. If your employees end up sitting around because they do not have anything to do, you end up wasting a lot of value.

- Transport - When materials or products are moved inefficiently.

- Motion - Lack of employee productivity. When there is too much time wasted between an employee finishes and starts a new task.

- Over-processing - Wasting too much time or resources on producing a product.

- Inventory - Having your existing inventory much higher than needed.

- Defects - The amount of time your employees spend fixing production mistakes.

To eliminate each type of waste, you can use either of these Lean tools…

PDCA

PDCA (also known as the Deming Cycle) is a framework for improving any given process. In the context of Lean Manufacturing, you use it to identify any of the 7 Deadly Wastes in a process and use PDCA to figure out how to solve it.

The cycle consists of 4 steps…

Plan - Find what the issue with the process is. Analyse it and start coming up with potential solutions.

Do - Implement the solution for a single process. It’s always a good idea to start doing this on a small scale to minimize risk.

Check - Compare the new process to the old. Is it performing better? Did you improve output? Lower input? Decrease production time? If the solution is effective, you move on to the next step.

If not, you start the PDCA cycle all over again.

Act - Once you’re sure that the process improvement will be beneficial long-term, you can implement it company-wide.

Want more in-depth information on the Deming Cycle and how you can use it to improve processes? Check out our guide to PDCA.

Kaizen

Kaizen is a Japanese word and means change (kai) for the better (zen). The goal of this methodology is to eliminate waste and achieve continuous improvement in your business by involving all of your employees - all the way from C-suite to assembly-line workers.

Unlike PDCA, Kaizen is a bit less practical. It focuses more on instilling a culture of improvement in your organization rather than telling you the exact steps you would need to take to improve a process.

To adopt Kaizen in your organization, you need to enable all of your employees to participate in process improvement. Their contribution and ideas should be both encouraged and rewarded.

There are a lot of practical ways to do this, but one of the most straightforward ones is the adoption of “Kaizen Corners.” The idea here is to create a space where all of your employees can go and leave their ideas for improvements.

Then, you should analyze each suggestion and potentially implement it.

If you make it clear that improvement and innovation are rewarded in your organization, you will see a lot of initiative from your employees.

The Kaizen Corner is only one means of achieving Kaizen at your workplace. To get more in-depth information about the topic, check out our complete guide!

Kanban boards for visibility

One practical tool that pairs beautifully with Lean is the Kanban board. Originally developed at Toyota, Kanban gives everyone a visual snapshot of work flowing through the system. You create columns representing stages - “To Do,” “In Progress,” “Review,” “Done” - and move tasks across as work progresses.

What makes Kanban powerful for process improvement is the transparency it creates. When work piles up in one column, you have found your bottleneck. When items sit stalled for days, something is blocking progress. The board does not lie. In my experience, teams that visualize their workflow this way catch problems weeks earlier than teams relying on status meetings and spreadsheets. The physical act of moving a card (or its digital equivalent) also creates a small sense of accomplishment that keeps momentum going.

Business Process Management (BPM)

Business Process management is a methodology for continuous improvement. The main idea behind it is that you should be constantly analyzing and optimizing business processes.

Unlike the other process improvement methodologies we have mentioned so far, this one is a bit more hands-on. It involves repeating the following cycle (called the BPM Lifecycle) as many times as needed on any given process.

- Analyze - Find potential improvements in the process.

Is it as cheap as it can be? As fast as possible? Can it be, partially or fully, automated?

-

(Re)Design - Once you have found the improvements in step #1, you can now redesign the process completely, or just make a change or two to the existing process.

-

Execute - Start using the new process at a small scale. This is more of a testing stage - you do not want to make company-wide changes until you know they are really beneficial.

-

Monitor - Keep track of the KPIs of the new process and benchmark them to the old.

Keep in mind, though, that it is a good idea to have the test running for a long time. You want to make sure the improvements are long-term. You might, for example, end up improving process output, but at the time, increasing defect rate.

- Optimize - Now that you have the data, you can make further improvements to the process until it is performing to your expectations.

This is, as a given, not something you do just once or twice. You do it continuously throughout the years.

This ensures that your processes are as efficient as possible.

For your BPM initiative to be successful, though, you need to use the right tools…

Business Process Management is not the easiest of methodologies to master. Want to learn how to use BPM effectively? We have a guide for that!

Process mapping (software)

To get the analysis phase right, you need to have a very good understanding of the process. Unless you’re the one in charge of carrying it out, though, you probably don’t know everything that it consists of.

The best way to get the right know-how is to create a process map. In most cases, this is done in the form a process flowchart.

Meaning, you create a flowchart of the exact tasks that need to be completed for the process to be finished.

Before you can start with this, though, you should pick the right tool. You could simply use pen & paper, but that is not all that useful.

You want the process graph to be digital so that you can share it with other employees, save it, use it as an SOP, etc. So, you are better off using an online process mapping tool such as LucidChart or Draw.io.

Once you have picked the tool, here is exactly what you have to do…

- Identify the process to be mapped. In this case, it should be whichever process you are improving using BPM.

- Bring together a project team. This should consist of employees related to the process, someone from senior management, and a process improvement expert.

- Gather the information about the process from the employees that are familiar with it.

- Create the baseline process map using your favorite tool.

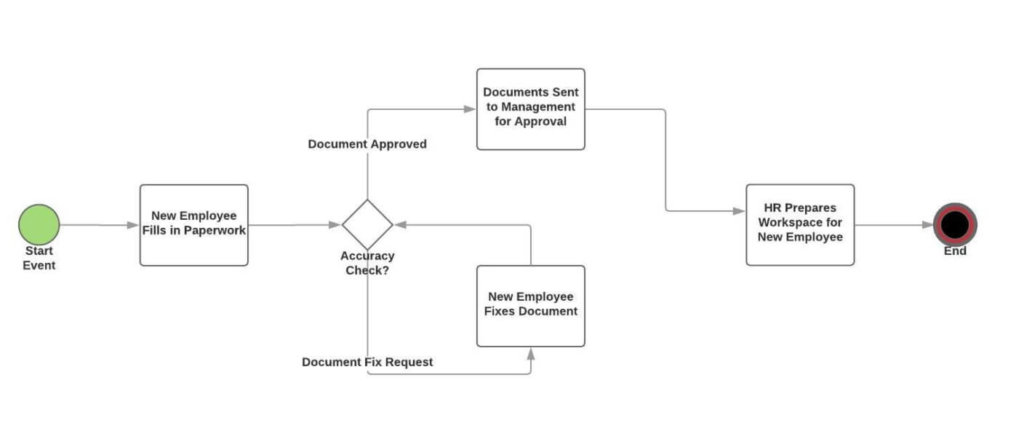

The end result should look something like this…

process flowchart example for employee onboarding

Want to master business process mapping? There is a lot more to learn! You can, though, learn everything you will need to get started with our step-by-step guide to process mapping.

Business Process Management software

One of the biggest issues with process improvement is making your changes stick. Sure, you spend a lot of time and resources in order to make the process better.

At Tallyfy, we’ve seen that all your efforts will be in vain unless everyone uses the new process on a regular basis. One glass installation company we worked with had a 22-step process for complex projects spanning five phases - from initial customer contact through post-installation follow-up. Before using workflow software, they tracked everything manually. The difference? Steps got missed, handoffs between estimating, operations, and installation teams broke down, and nobody could see the full picture.

While your employees are all in favor of improvement, they are not big fans of change as a whole. As is the issue with most company change initiatives, you need to ensure that the employees are on-board.

The easiest way to get them used to new processes is by using Business Process Management Software (BPMS).

The gist of the software is that it helps you create digital processes.

Instead of having to go around telling your employees about the new changes and how they are supposed to do things differently now, all you have to do is make the edits online.

The software notifies the relevant employees about the changes and starts enforcing the new process rather than the old.

BPM software has a lot of other capabilities in addition to what we have mentioned so far. Want to learn more? Check out our guide to BPMS!

Conclusion

Now that you know about the most important process improvement methodologies, it’s time to put them into practice. Pick one and start. Start experimenting with your business processes and you will start seeing improvements in no time.

Here is the trap I see teams fall into: they try to deploy DMAIC, PDCA, Kanban, Kaizen events, and value stream mapping all at once. It becomes chaos. Too many frameworks competing for attention means none of them get applied well. Pick one methodology that fits your biggest problem. Master it. Then consider adding another tool to your toolkit. Small, steady improvements beat elaborate transformation programs that collapse under their own complexity.

If you want to learn more before getting started though, you might want to head over to our complete guide to process improvement tools.

Ready to put process improvement into practice? Discover how Tallyfy helps you document, track, and automate your workflows.

Is good enough actually good?

Are you hearing this at work? That's busywork

Enter between 1 and 150,000

Enter between 0.5 and 40

Enter between $10 and $1,000

Based on $30/hr x 4 hrs/wk

Your loss and waste is:

every week

What you are losing

Cash burned on busywork

per week in wasted wages

What you could have gained

160 extra hours could create:

per week in real and compounding value

Total cumulative impact over time (real cost + missed opportunities)

You are bleeding cash, annoying every employee and killing dreams.

It's a no-brainer

Related questions

What are the common process improvement methodologies?

Process improvement methodologies are approaches to make work better and smoother. The most popular ones are Lean, which is about eliminating waste and unnecessary steps; Six Sigma, which seeks to eliminate mistakes and errors; and Kaizen, which believes in making small, incremental improvements daily. Every method has a unique perspective of problems that need to be solved, but a common objective: to make work easier and better for everyone.

What are the five stages of process improvement?

The five steps of process improvement take an unenlightening path: You establish what needs to be fixed. Second, you take stock of the current state, with data.

And third, you study the data to identify the root causes of the issues. Fourth, you get smarter by changing things and trying other ways to solve problems. Lastly, you manage and track the changes to ensure they survive and continue to perform well over time.

It’s like fixing a bicycle - you find the kink, check everything, figure out why it’s not working, fix it and make sure it runs smoothly.

How do you choose the right process improvement methodology?

The right approach depends on what you are trying to solve. If you are working with a lot of errors, you might be best off with Six Sigma.

If the point of your business is to do things fast and with low waste, then Lean might be great. Consider what skills your team has, how much time you have and what kind of problem you are trying to solve. It is the way that you pick the right tool out of a toolbox - you go for the tool that fits the job that you need depending on what you are doing.

What makes a process improvement project successful?

Succeeding at improving processes is really a matter of several key things: having clear goals that everyone understands, gaining support of leadership, engaging the folks who actually perform the work, and honestly measuring results. The secret sauce is getting everyone affected by the changes on board and understanding why things are changing. “It is like planning your road trip,” he said, “you need to have a place you want to go, you need a good map, and you want everyone in the car to be happy to go on that journey.”

What are common mistakes in process improvement projects?

The most common mistakes are wanting to change too many things all at once, not involving the right people, not being clear in the way the message is communicated, and giving up too soon when things get tough. Another major mistake is to concentrate on tools and methods and to ignore the human aspect of transformation. It is like building a house: You have to have good plans and tools but also make sure everyone working on the house knows what they are doing and gets along.

About the Author

Amit is the CEO of Tallyfy. He is a workflow expert and specializes in process automation and the next generation of business process management in the post-flowchart age. He has decades of consulting experience in task and workflow automation, continuous improvement (all the flavors) and AI-driven workflows for small and large companies. Amit did a Computer Science degree at the University of Bath and moved from the UK to St. Louis, MO in 2014. He loves watching American robins and their nesting behaviors!

Follow Amit on his website, LinkedIn, Facebook, Reddit, X (Twitter) or YouTube.

Automate your workflows with Tallyfy

Stop chasing status updates. Track and automate your processes in one place.