What is lean management - How to make processes leaner

Learn what Lean Management is and how you can implement lean management to make your processes leaner, lower costs, and increase overall process efficiency. Follow this step-by-step guide on lean process management.

Lean management eliminates waste through continuous improvement.

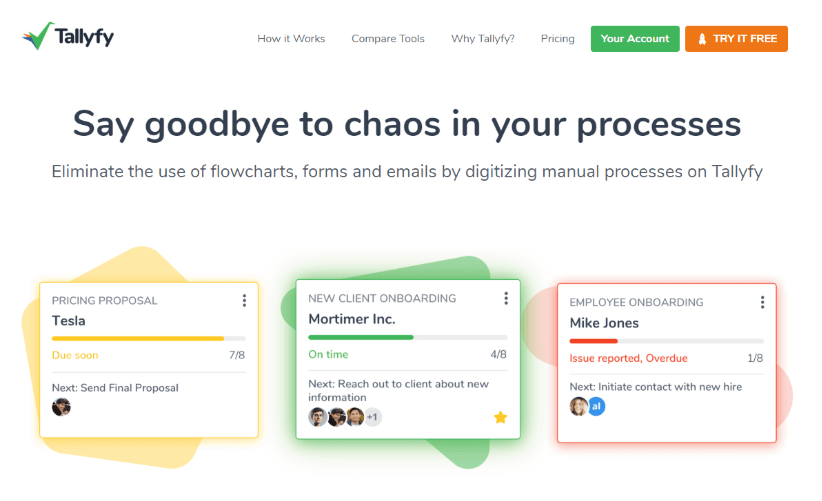

Tallyfy is Process Improvement Made Easy

Summary

- Toyota invented lean to eliminate waste - Starting in the late 1940s, Toyota built a philosophy around continuous improvement and customer feedback, cutting processes that added no value to the end client

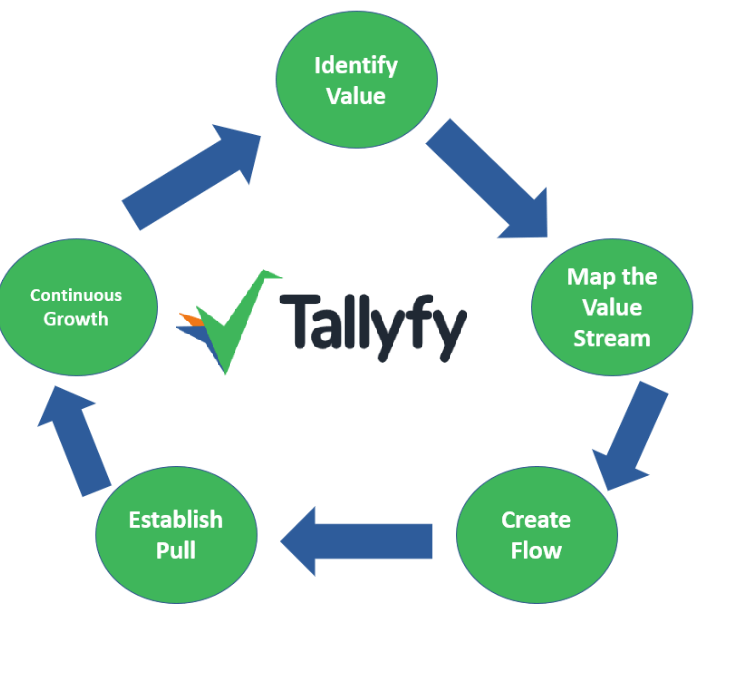

- Five principles drive lean implementation - Identify what customers actually value, map your entire workflow to spot waste, create smooth flow without bottlenecks, produce only what is needed when it is needed (pull), and pursue continuous improvement forever

- Benefits include quality gains and cost cuts - Lean reduces redundancy so employees focus on quality control instead of wasteful tasks, cuts inventory costs, and improves sustainability, but requires upfront training investment and creates supplier dependency

- Fix processes before automating them - Inputting broken workflows into software just creates automated chaos, so identify duplications and make it work manually first before using tools to monitor flow and track KPIs. See how Tallyfy supports lean workflows

In the contemporary business world, more and more companies are entering the market and striving for the same target group. As a result, competition grows more vicious with each passing day and businesses ought to find ways to reduce customer churn and to gain a competitive advantage over others. One way to gain such is through a philosophy known as lean management.

What is lean management

Lean management is a concept, an approach to running a company by bringing exceptional value to your customers via continuous improvement. Its implementation aims to achieve small, yet incremental changes in business processes, on a regular basis, in order to result in higher efficiency, quality, and customer satisfaction. Thanks to its nature, lean management has become a widespread process across many industries and fields.

How lean management came into being

The idea about a boost in efficiency and quality came in the late 1940s by Toyota. Their idea was to enhance customer satisfaction by eliminating all processes which do not contribute or bring any value to the end client.

The two main pillars of lean management are to seek continuous improvement of the problem and to pay close attention to consumers’ feedback.

This philosophy achieved great results and established the car manufacturing company very highly in the eyes of customers. It just worked. Manufacturing represents about 8% of our conversations at Tallyfy, and in our experience, the companies that truly embrace lean thinking typically see 60-65% reductions in cycle times within the first year. One payroll services team cut their client onboarding from 14 days to 5 days by eliminating waste in their documentation collection process. As a result of that, many other companies embraced the lean manufacturing process in their own industries. Whether they are business-to-business (B2B) or business-to-consumer (B2C) oriented and have scored substantially better results than before.

Simply put, lean management can also be referred as “waste management”; regardless of whether you are owning a profit-driven business or an NGO, you need to discontinue processes which are not working or resulting in loss of sales; you need to eliminate malfunctioning programs; most importantly, you need to acknowledge the customer’s point of view, in order to identify opportunities.

Benefits of lean management

Lean process management has a wide variety of applications in the modern business world and even a wider list of benefits. Here are some of the most ubiquitous:

- Enhanced quality - by eliminating redundant processes, the quality of the market offering inevitably improves, as your employees will be free to focus on quality control rather on “wasteful tasks”.

- Sustainability - less redundancy in business processes that do not contribute in any way means higher sustainability and better adaptability in the long-run.

- Stronger brand recognition - your brand reputation will surely rise once you pay attention to your customers’ needs and reduce noxious processes.

- Manpower reductions - lean process management helps you get more things done with fewer people. When the process is fully optimized and made efficiently, your employees will produce faster and will not waste time on menial tasks.

- A decrease in cost and an increase in profits - higher productivity and better quality with less redundancy mean a significant cut in an increase in sales.

- Reduced risk of overbuying and less reduced space - with lean management space will be created due to the waste reduction process.

This is because the reduction in raw inventory will save up additional space which can be used more efficiently, such as buying inventory for the production of a new product. And this is just a cursory list of the full extent of lean management’s power. But like any other process implementation, this, too, has limitations.

Drawbacks of lean management

Even processes that aim for quality improvement face difficulties and can sometimes backfire.

Here are some of the most renowned disadvantages of lean management:

- Resistance among employees - it is a general rule that many employees are reluctant to embrace change, especially if they have been in the company for a long time. Therefore, it is obligatory to provide pieces of training and to make your coworkers understand the need to embrace lean management as a mandatory process for growth.

- Inventory problems - holding a lower amount of stocks is a traditional practice with lean management in order to cut extra costs. But this would make you dependent on your suppliers. That way, the timely and efficient delivery of goods will be of vital importance to you and any disruption of inventory processes can cause plenty of headaches.

- High implementation cost - implementing lean in a company that has never used it before might force all ongoing production processes and systems to end in their present state. This, in turn, will result in higher costs in regards to organizing training for employees or bringing new equipment. Such a limitation can be noxious for small and mid-sized companies whose financial capabilities are easily depletable.

- Extra costs from implementing a proper IT system - A process such as lean depends on complex procedures and constant monitoring. Thus, it would oblige you to implement proper enterprise resource planning (ERP). Only through such systems, you can accurately monitor what is happening within the company and what processes are menial or redundant. This, though, can be a costly solution, especially for smaller companies. Regardless that lean management aims to improve quality, such disadvantages remain issues to many.

Implementing lean process management in your business

Here is a step-by-step guide on how to employ lean process management in your company:

Set clear goals

Before you start, you need to find your “why”. Many organizations know how to carry out their processes but they don’t know why they’re doing them.

Therefore, you must know where you are right now, where you are heading, and by what means you are reading that destination. If you are to ignite this philosophy change in your organization, you need to convince your team first. This can only be achieved by setting clear goals with a specific strategy.

Then, you will be able to set a clear path for others to follow, to motivate their thinking, and to navigate their work processes by diminishing hindering processes.

After you have defined clear goals, it is time for the real challenge - asking others to embrace this idea

Ensure your staff is coached and prepared

The “one-man-army” philosophy is long gone in the contemporary business world. No matter how many great ideas or strategies you have, if you cannot find the right team to support you, you will be out of the race in no time.

As a result, you must prepare your team for the upcoming change. Something more - you need to convince them to embrace the lean philosophy and to coach them on how to carry out their everyday activities with their new lean mindset.

But you need to note that dealing with the human factor can sometimes thwart your plans and make the working process even more complicated. This is because convincing everyone to embrace something different might be a major challenge - remember, most people are afraid or reluctant to change.

Therefore, it is up to you to familiarize your coworkers with the lean management philosophy, to explain to them its benefits from both an organizational and a personal perspective. You need to convey to them that this concept is tightly connected to adding value.

This, in turn, will ideally result in higher profits for the company. And greater opportunities for them do continuously develop in a well-respected company.

People avoid change not because they don’t believe in it. But because they’re afraid that they won’t be part of it. As a result, it is up to you to explain to them that all of you, together, should embrace the lean philosophy and develop, both as individuals and as a team.

Introduce your team to the 5 lean management principles

Once you have made your team embrace the change, you will have to introduce them to the five main lean management principles.

-

Identify value

The value is the part of the solution that your client is desperately willing to pay for. Any additional activity which does not bring value to the end product or customer is considered redundant.

Thus, prior to starting with anything, you must first identify the value that you want to deliver to your target audience. You should note that when identifying value, you should be looking at the big picture. It is mandatory to be taking into consideration all actions connected to the processes from producing equipment to its dispatchment.

Otherwise, you might make a wrong judgment and identify a valuable process/employee as waste, or vice-versa. 2. #### Map the value stream

This is the step in which you need to map the workflow of your organization. You have to include all the people and actions involved in creating and dispatching your end product to the client.

By doing the map, you will be able to visualize the whole production process. You can then identify which of the involved people or actions make the process tardy and ineffective. This “big picture” will enable you to easily identify all the menial steps which bring no value and to cross them out.

Follow this link for more information on how to implement value stream mapping into your processes.

-

Create a flow

Next, you need to ensure that this workflow remains efficient and smooth. Even though this is not an easy task, you need to monitor the process so that it always brings value

This step is extremely vital as it consists of monitoring the processes that you have mapped. And making sure that they run smoothly.

It is important to note that creating a flow can be a pretty menial task itself. It requires a great amount of devotion, attention to detail, and critical thinking. Thus, there are two widely adopted ways to achieve it.

The first one is to choose the long road and go for manual flow creation. This is a cost-effective manner under which you should break up the work and processes into smaller segments and assign managers to measure specific KPIs in order to monitor if the maximum value is delivered and additional waste can be cut.

You should note, though, that if you and your co-workers lack time and have various responsibilities, this method might not be the best option, as it would deplete a substantial percentage of your time.

The second option is to go for specialized software that will monitor the flow on your behalf. It will achieve monitoring the sole process through workflow automation and will save you the trouble of micromanaging every single action, in order to gain the desired result.

Even though this is a slightly costly solution as opposed to the former one, it can be a real lifesaver, especially if time is precious and limited for you. Such software, that you may consider is Tallyfy, for example.

We will go more in-depth on how you can use Tallyfy in implementing lean management in the next section. 4. #### Establish pull

By definition, a pull system means that you bring a market offering to somebody provided there is a demand for it. The difference between push and pull is that in the former strategy, managers assign tasks on their co-workers on a regular basis, even if these tasks are not of high priority.

When going for a pull strategy, the tasks are usually assigned in a queue. Each one of which with a specific priority. The idea here is that tasks will be assigned to workers only if they are of high priority or if there is a demand for it.

By establishing such a system, you will be able to optimize and utilize current stock inventory. This probably helps you deliver the right product/service to the right audience at the right time.

When implementing lean process management, you need to focus on two things: cycle time and effectiveness of completion of tasks. The idea is to train your team to aim for shorter cycle times while effectively completing tasks.

-

Continuous growth

Implementing the first four steps is only 50% of a job well-done. The remainder lies within successfully sustaining lean management and looking for opportunities to make the process even better.

If you want to do this step properly, it is mandatory that you trust your managers. And you must share your set of responsibilities with them.

As much as micromanagement is efficient in many cases. Going through the aforementioned steps all by yourself can be difficult. And striving to be everywhere at the same time can cost a great deal of time and resources.

Thus, it is always a great idea to train your managers. Show them what you are looking for, establish concrete KPIs. And let them carry out your tasks.

Seeking continuous growth and improvement is not an easy task. However, it is a must when you are striving to implement a process such as lean management.

If you have followed the last 3 major steps meticulously, you should have a convenient lean management system in your company adding value to customers. However, it is important to note that the process explained above can be really menial and time-consuming. Especially if done manually or from scratch.

Establishing a lean mindset is not that easy because it requires a lot of devotion, time, and expertise. As a result, following the aforementioned steps manually might cost you a great deal.

We live in the digital age, where all kinds of shortcuts are right at our fingerprints. This is why if you are seeking to implement a lean system but lack the needed time or expertise, you can always use business process management software (BMPS) to automate tasks for you and help you out.

Automation in lean process management

Such solutions can easily automate processes within your company as the software will manage their task-execution and alert your team once something is ready.

But you need to keep in mind that many of the online solutions are pretty expensive; thus, if you’re on a shoestring budget, you might want to do very in-depth research on what the market has to offer.

After all, the idea is to integrate software that would scale with your business and bring profit. Not cost you a sum beyond your planned budget!

Go for Tallyfy

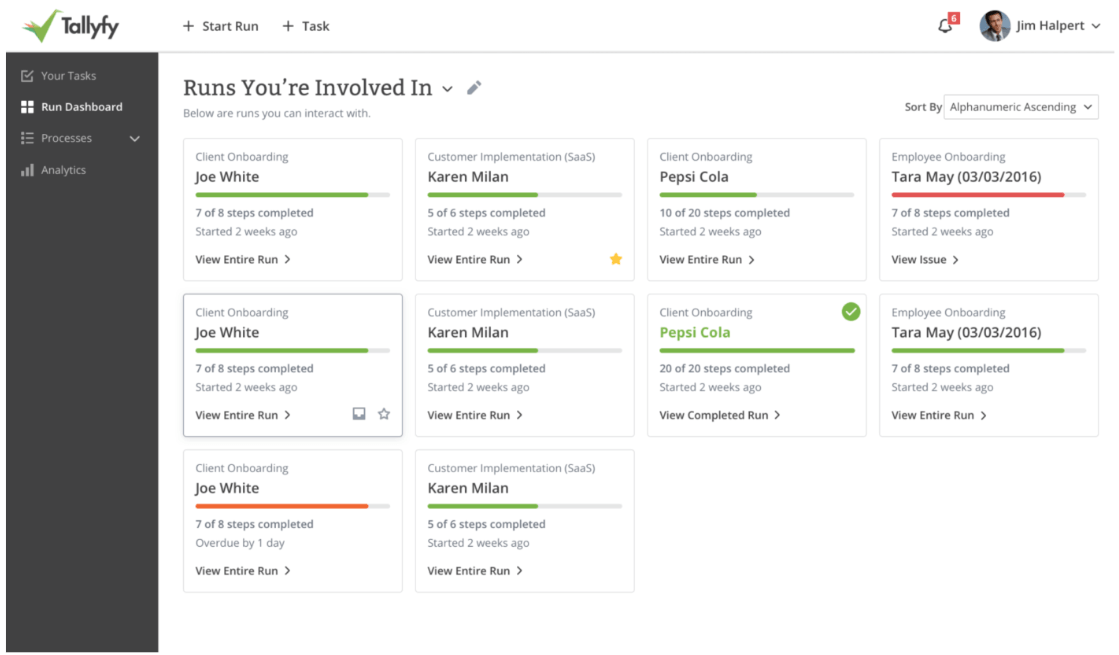

Such an online solution that you may use is Tallyfy, thanks to its wide array of features and interface flexibility.

Tallyfy is business process management software that helps you automate processes and move to execute business decisions faster without you and your team worrying about repetitive tasks. Simply put, it is a cloud-based integration tool that aims to eliminate workflows and to make your life easier. Let us go through implementing the five principles above but with this software’s help:

Identify value with automation software

An essential part of identifying value for customers is through conducting primary research techniques and analyzing them afterward to identify new trends and be more competitive.

But manually storing and analyzing survey results can cost you a great deal of time, which you might lack. Also, hiring somebody just for that would be an extra cost. A redundancy, according to the lean process management which you are going for.

Through Tallyfy, however, you can easily set it to automatically collect and store survey data in your drive. While you can focus on other duties of a higher significance. Then, you will be able to have your specialists access it and analyze it. Without having to dig into hundreds of emails in order to get the results.

Beyond that, through Tallyfy, you can identify value in other ways, too. You can set it in such a way that it will automatically notify you when somebody posts a review about your brand.

That way you can always track what people think about your company. You can gain insights on what people are looking for and what you should focus on.

Map the value stream with Tallyfy

As handy as it may be, when done manually, this process can be really tardy and menial. This is because by the time you map the process, analyze your results, discuss them internally with your team, think of a solution, and decide on its implementation, your competitors might have already done this faster than you.

Thus, you risk losing your competitive advantage by bottlenecking yourself with time-consuming tasks.

With Tallyfy’s help, however, mapping the value stream can turn from a menial responsibility to something effective and fast. Not only does the software allow you to map the process efficiently.

It also provides you with the opportunity to manage how the process is doing even after the mapping period. That way, it will be easier for you to identify potential wasteful tasks, bottlenecks, underperforming processes/employees, etc.

Also, through this mapping, you and your coworkers can easily keep track of your to-do list and reduce the chance of missing a deadline.

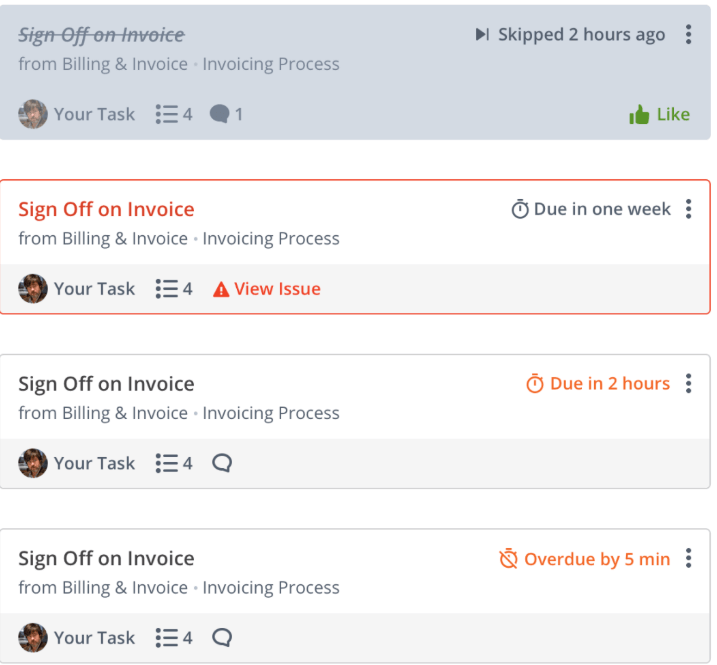

Create an automation flow

Through automation software, it will be easier for you to manage the flow you have created. And to make sure that the implemented processes are going smoothly.

For example, you can set specific KPIs and notifications to alert you each time someone finishes a process. This way you can measure its performance and see what can be added, removed, or improved. This BMPS allows to easily monitor the status of tasks, to prioritize them based on significance, and monitor ongoing deadlines.

For example, you can set specific KPIs and notifications to alert you each time someone finishes a process. This way you can measure its performance and see what can be added, removed, or improved. This BMPS allows to easily monitor the status of tasks, to prioritize them based on significance, and monitor ongoing deadlines.

That way, you will be receiving notifications about each step and you and your co-workers will always be informed.

Establish a pull system

The pull strategy mindset does not need specific automation workflow software. However, the allocation of tasks and their monitoring does.

By implementing Tallyfy, you can monitor how tasks are going and if there are close deadlines. For example, imagine that there is a demand for your product (let us say software). You assign these tasks to your programmers.

You can create a flow that will automatically alert you once your programmers finish it and send you the information. That way, you do not need to micromanage them or constantly view your email. You will be able to focus on your tasks and a notification will come once the work is done and sent.

The same rule applies when sending invoices or doing anything manually. Even though Tallyfy does not directly contribute to the pull strategy, it proves to be an effective solution for automating tasks and implementing lean management in the long-run.

Continuously improve your processes with Tallyfy

Based on the aforementioned steps, Tallyfy is indeed a tool that can optimize processes. Streamline your operations, make processes more expedient, and scale with your business.

Also read continuous process improvement.

The best part about this cloud-based solution is that it is extremely affordable for smaller or mid-sized companies. It also has a free-trial option for you to try out.

This gives you the opportunity to get the full extent of lean management implementation at a low-cost. And, in case you like it, you can always upgrade your subscription to a Basic, Pro, or Enterprise.

Final takeaways

To wrap it up, lean management is a philosophy that proved to be a winning strategy and to benefit those who have implemented it. In a market swarming with competitors, you must add value and eliminate redundant (for buyers) processes. In our experience, the organizations that sustain lean gains long-term are those that make continuous improvement part of their culture, not just a one-time initiative. We have seen legal firms double their case capacity by replacing Excel spreadsheets with standardized process templates, but only when they committed to refining those processes weekly rather than treating the initial setup as the finish line.

Nevertheless, implementing one, albeit it seems easy, can deplete a lot of precious time and resources. As a result, you should consider automation software to simplify tasks and make the processes run even more smoothly.

This is why we, from Tallyfy, are here to support you. Our software can handle multi-transactional complex tasks and support you in your lean quest while scaling with your business.

Give our free trial a chance by clicking here and let us take care of the redundancies for you while you are busy adding value to those who need it.

Related questions

What are the 5 principles of lean

The 5 principles of lean are akin to a recipe for making more value with less waste. One, clearly identify what customers value - not what you think they want.

Second, map the work you are doing to see where value is created. Third, make it easy to work by eliminating bottlenecks and delays. Fourth, produce only what customers want when customers want it (this is known as pull).

Lastly, continue getting better and better until you reach perfection - even if you will never get completely there, and that is perfectly alright! Think about how you clean your room - you decide what to save, organize it, make it easy to find things, throw out old stuff, and continuously find ways to improve it.

What are the 5 stages of lean

The lean transformation occurs over the five levels, which create on another. It starts by identifying what the customer values, and from there it is about creating a value stream map - essentially a GPS route for your work.

The next step is setting up flow, where you make work happen naturally without the starts and stops. The fourth stage establishes pull systems, where work is only initiated when there is demand. And the last phase is consistently striving for perfection through incremental steps.

It is like a stepping stone, and you have to master one before moving to the next.

What are the 5 main steps of the lean manager

There are 5 critical practices in the work of a lean manager that happen every day. They begin by going to the place where the work is done (gemba) to see it for themselves.

Then they ask questions to understand the problems, not rush to a solution. Third, they teach and train others to solve their own problems. Fourth, they get behind ideas for improvement from their subordinates.

Finally, they set up systems that preserve and expand the gains. It is like being a coach who develops players and then gets out of the way and lets them play.

What is an example of lean management

An easy way to think of lean management: A coffee shop was able to cut customer waiting time from 8 minutes to 2 minutes. They did it by watching how drinks are made and looking for wasted motions.

They reorganized their equipment so that a barista would not have to walk around to get to anything. They also had staff trained to make drinks a certain way, and carried only the ingredients that they needed. The result?

Happier customers. Less stressed workers.

More sales. This demonstrates how lean thinking can be applied to everyday work to make things better and easier, rather than just replacing one set of tools and habits for another.

What is the role of leadership in the success of lean management

Lean management success depends on how leaders do, not just what they say. They have to be gardeners, creating the conditions for improvement to flourish. That means hanging out at work and time with your team, asking good questions rather than providing answers, and recognizing incremental accomplishments. Leaders must be patient because lean changes are slow, and focus on developing people and not just fixing processes. When those in charge exhibit these behaviors, teams feel comfortable experimenting and iterating.

How does lean management differ from traditional management

Lean management stands traditional management on its head in fascinating ways. Where traditional managers may sit in offices and make decisions, lean managers dwell where work is done.

Conventional management first focuses on results, but lean thinks about the genesis of those result. It is like cooking and the traditional management just wants the meal as fast as possible, but the lean is interested in making the cooking better. Lean also is based on the belief in the capacity of workers to improve their own work, rather than forcing improvement down from above.

What common mistakes do companies make when implementing lean

Companies tend to make predictable mistakes with lean. Some people are treating it as a quick fix, rather than a long-term journey.

Some are and some developers focus more on tools and charts than on changing how we think and work together. Others attempt to replicate exactly what worked elsewhere, without realizing that every workplace is different. Failing to involve everyone in improvements: lean will work best when everyone is improving work, from the cleaning person to the CEO.

How does lean management impact employee satisfaction

When implemented successfully, lean management can actually make work more satisfying by opening more control to employees over how they do their jobs. It values their ideas and experience, involves them in fixing problems and takes away annoying hindrances from their day. Employees often say that they feel more connected for being able to see how their work creates value. It is like being on a good sports team, except instead of it being only those who are able to follow orders from a coach, a wide diversity of people could help win.

What tools are essential for lean management

Lean is not about tooling, but tools can help you see waste and solve problems. Visual management boards make problems and progress visible.

Best-known methods, or standard work instructions, ensure everyone does a task the best-known way. They make visible how work flows (or not). Thinking about problems is facilitated by A3 problem-solving sheets.

But keep in mind - these are more like kitchen gadgets. They help, but they do not actually make the meal - that is the cook’s job.

How do you measure success in lean management

The measurement of lean success is much more than measuring the money saved. Just consider how long things take all the way through.

Test If Quality Is Improving. Check to see whether employees are posting more improvement ideas. Keep an eye on whether problems get solved more quickly.

These measures inform you if you are actually getting better, as opposed to just looking better on paper. It is like tracking your fitness - you check a constellation of indicators; strength, speed, stamina; not just weight.

About the Author

Amit is the CEO of Tallyfy. He is a workflow expert and specializes in process automation and the next generation of business process management in the post-flowchart age. He has decades of consulting experience in task and workflow automation, continuous improvement (all the flavors) and AI-driven workflows for small and large companies. Amit did a Computer Science degree at the University of Bath and moved from the UK to St. Louis, MO in 2014. He loves watching American robins and their nesting behaviors!

Follow Amit on his website, LinkedIn, Facebook, Reddit, X (Twitter) or YouTube.

Automate your workflows with Tallyfy

Stop chasing status updates. Track and automate your processes in one place.