Continuous improvement: keys to success

The consistent buzz about continuous process improvement has been present for more than three decades - to the point where it is becoming a background hum.

Continuous improvement requires systematic measurement and iteration.

Tallyfy is Process Improvement Made Easy

Summary

- Deming Cycle drives continuous improvement - Plan (identify goal, formulate theory, define success metrics), Do (implement plan), Study (monitor outcomes for progress or problems), Act (integrate learning to adjust goal or reformulate theory). These four steps repeat over and over as continuous cycle

- Only 1 in 3 improvements has financial impact - KaiNexus research shows just 13% of improvements save money and 23% save time. Despite low success rates, global marketplace demands enterprises adapt, innovate, and grow. No industry leaders have remained static without incorporating ongoing process improvements

- Must integrate into corporate culture for success - C-suite team cheerleads continuous improvement down to last person. Everyone writes the CI book and works on editing it together. Cherry-pick optimal continuous improvement use based on business objectives, industry shifts, and global economy changes

- Balance incremental improvements with breakthrough thinking - Six Sigma team streamlining information flows failed to question how data was ultimately used. Once they did, they eliminated much data and freed thousands of hours redeployed to customer-facing activities. Cycle of breakthrough thinking followed by continuous process improvement is best chance at global competitive edge. See how Tallyfy supports continuous improvement

Quality and compliance topics appear in over 1,500 combined conversations we track with mid-market teams. The consistent buzz about continuous improvement has been present for more than three decades by now - to the point where it’s in danger of becoming a fading background hum. That presents a real danger for enterprises seeking to attain, and retain, a competitive edge in their respective industries. We need to understand what successful continuous process improvement looks like. Why?

1 in 3 improvements has a financial impact. 13% of improvements save money. 23% of improvements save time.

- KaiNexus

Point to any industry in which the most successful companies have remained static - incorporating no ongoing process or product improvements. You can’t do it. In the global marketplace where outsourcing, partnerships, technical solutions, and flexibility to pivot rule, enterprises thrive only when they adapt, innovate, and grow. Increasingly savvy buyers demand continuous improvement in exchange for their brand loyalty.

At Tallyfy, we have seen one service business that implemented systematic process improvement achieve a 75% reduction in headcount - from 65 employees to 15 - while simultaneously achieving a 4X revenue increase. The key was eliminating redundant and outdated tasks that staff were performing without anyone questioning whether the work was still necessary.

What is successful continuous process improvement (CPI)?

First, a look at what continuous improvement (CI) is not. CI isn’t an add-on to a process any more than is turning a screw to the right to tighten it, or to the left to loosen it. CI isn’t letting each department or team go off on its own to solve a piece of a problem in a vacuum. Nor is it “a change” - although beginning to implement it may be one.

Now a look at what continuous improvement is

Simply put, continuous process improvement is a systematic approach to an ongoing review of workflows and outcomes to identify ways to improve them both. The approach was schematized as the Deming Wheel or Deming Cycle by Dr. W. Edwards Deming who credits his mentor, Walter Shewhart of the Bell Laboratories, with the idea.

As described by the W. Edwards Deming Institute, Deming’s cycle contains four stages: PLAN, DO, STUDY, and ACT:

- Plan involves identifying a goal or purpose, formulating a theory, defining success metrics, and putting a plan into action.

- Do involves implementing the plan.

- Study involves measuring and monitoring outcomes to test the validity of the plan for progress and success, or problems and areas to improve.

- Act integrates the learning generated by the entire process, which can be used to adjust the goal, change methods, or even reformulate a theory altogether.

The four steps are repeated over and over as part of a continuous cycle.

Ralph Keller sets out the overarching idea well in this issue of Industry Week:

The key to differentiating your company is that your competitors do not design products, process orders through customer service, manufacture them in your plants or even sell and distribute them exactly like you do, and that is where you can create a uniqueness that could yield a competitive advantage. It’s also where your continuous-improvement (CI) projects are concentrated.

What aspects of my enterprise are affected?

Good question. The short answer is, it depends.

Consultant Brad Power in the Harvard Business Review suggests that it is best to cherry-pick your optimal use of continuous improvement:

Startups do not need process improvement; everyone in the startup has to be obsessed with getting their new product or service to market, even if it is sloppy. Companies with blockbuster products such as a patented drug or a breakthrough smartphone can be grossly inefficient in production, delivery, and service and still be successful. Executives at companies like Google, Apple, and Nike… do not need to focus on excellence in every process; the process they need to focus on to achieve or maintain industry leadership is product development.

Power adds that where you choose to emphasize continuous improvement may change over time to better align with shifts in your business objectives, your industry, and the global economy. This matters. IBM has remained competitive for decades doing exactly that.

The secrets to successful continuous process improvement

The key secret to successful continuous process improvement is its absorption into the corporate culture and dynamics of your enterprise. For that to happen, the C-suite team - not just the VP of QA - don the role of cheerleaders-in-chief and ensure that their workforce, down to the last person, is on board.

-

This goes beyond the notion that everyone is on the same page; rather, everyone writes the CI book, and then everyone works on editing it, as well.

-

Tallyfy’s post - about crowdsourcing ideas for process improvement contains tips on the successful integration of continuous process improvement into your workflows in ways that eliminate resistance to “change” and instead, engage your workforce in identifying efficiencies.

The second secret is finding the right balance between a focus on CI and the need for intuitive explorations of new ideas that may lead to true breakthroughs in processes, products, and services. Consultant and author Ron Ashkenas describes the need for and benefits of this type of balance:

Question whether processes should be improved, eliminated, or disrupted. … For example, a six sigma team in one global consumer products firm spent a great deal of time streamlining information flows between headquarters and the field sales force, but didn’t question how the information was ultimately used. Once they did, they were able to eliminate much of the data and free up thousands of hours that were redeployed to customer-facing activities.

Indeed, a cycle of breakthrough thinking followed by continuous process improvement (and repeat) is the best chance your company has to achieve and maintain a global competitive edge. It’s an idea for which consultant Becky Morgan offers case after case examples.

Why copying best practices rarely works

Here is something that trips up most companies trying to implement continuous improvement: they focus on copying the visible practices without understanding what makes those practices actually work. Toyota has been studied and dissected for decades. Consultants have written thousands of pages on their methods. Yet most companies that try to replicate what Toyota does fall flat. Why? Because the magic is not in any single tool or technique - it is in running all the pieces together as an integrated system, practiced every single day without exception.

You can photocopy someone’s kanban boards, steal their daily standup format, and implement their exact metrics dashboards. What you cannot easily replicate is the culture that makes those practices meaningful. The daily discipline of small improvements. The mindset that every person, regardless of role, has both the authority and responsibility to flag problems and suggest fixes. That cultural fabric takes years to weave, and no consulting engagement or training program can shortcut it.

Templates that support continuous improvement

Holding onto the gains you make

The other piece most improvement programs miss is what happens after you implement a change. You celebrate the win, move to the next project, and six months later discover the old problems have crept back in. This is not unusual - it is the default outcome when you treat improvement as a project rather than a system.

Every improvement needs a mechanism to prevent backsliding. This might be a documented procedure that becomes the new standard, automated checks that flag deviations, or regular reviews to verify the change stuck. Without this, you are essentially running on a treadmill - expending effort without actually moving forward. The unglamorous work of sustaining improvements matters just as much as making them in the first place.

Benefits of continuous process improvement

Benefits will begin to accrue once continuous improvement is woven into the fabric of every work process and viewed as “the way we work” rather than as a separate, added task to be performed.

Initially, internal efficiencies may emerge that simplify a process or assist a customer. Efficiencies in supply chain requests or communications, for instance, may shorten time-to customer deadlines and even offer budget savings. Further efficiencies may be found in looking at workflows and outcomes with outsourcing partners. And benefits don’t stop there.

We all know what continuous process improvement has achieved for the U.S. auto industry.

Benefits accrue regardless of the industry. Take, for instance, the financial sector. U.S.

Bancorp’s paper on the “Benefits of Continuous Improvement Initiatives” lists these “proven benefits”:

- Increased operational efficiency and productivity.

- Better documentation and elimination of redundancy.

- Greater quality awareness.

- Enhanced internal and external communication.

- Improved audit results.

- Faster and better decision making.

- Greater data reliability.

- Increased risk management.

Continual process refinement will probably lead to better products and services, and it’ll strengthen relationships with buyers and loyalty to your brand.

Another benefit - a more confident and engaged workforce - is likely to boost products, services, and overall satisfaction as well.

- Once the word gets around that your enterprise engages in continual review and tweaking of your processes and products, attracting and retaining the best and brightest workforce becomes easier.

Finally, you may have heard the expression, Don’t look back; someone may be gaining on you. With a company-wide reputation for relying on continuous improvement, competitors will be nipping at your heels as they try to reach and then pass you in the marketplace. That’s the key reason to ensure that your team never lets up on continual changes.

Is improvement continuous?

Are you hearing this at work? That's busywork

Enter between 1 and 150,000

Enter between 0.5 and 40

Enter between $10 and $1,000

Based on $30/hr x 4 hrs/wk

Your loss and waste is:

every week

What you are losing

Cash burned on busywork

per week in wasted wages

What you could have gained

160 extra hours could create:

per week in real and compounding value

Total cumulative impact over time (real cost + missed opportunities)

You are bleeding cash, annoying every employee and killing dreams.

It's a no-brainer

A summary on other ideas to consider to ensure success with your process improvement initiative are covered in the video below.

Keeping it going, continuously

The right software app is key to successfully standardizing improvements once they’re designed and initially implemented. That’s where Tallyfy’s process mapping and improvement tool comes in.

Tallyfy makes it easy to keep everyone working in tandem rather than at odds towards the company’s goals. The app offers a unique way to maintain progress already in place across the board while still enabling new improvements to bubble up for review.

Sign up for a free trial to learn how the app can map and track workflows, standardize and automate any repeatable process, and transform your success.

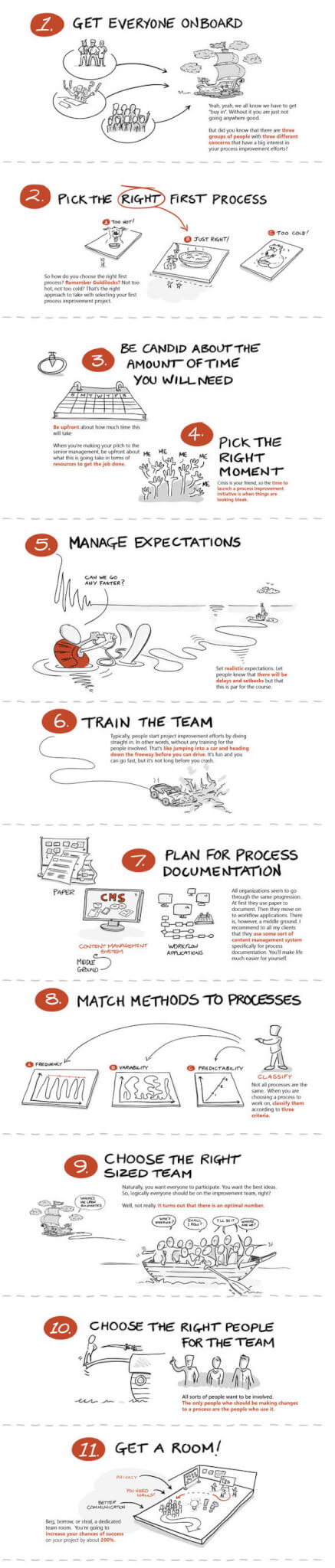

Bonus infographic - how do you prepare for process improvement?

Courtesy of the Process Consultant.

About the Author

Amit is the CEO of Tallyfy. He is a workflow expert and specializes in process automation and the next generation of business process management in the post-flowchart age. He has decades of consulting experience in task and workflow automation, continuous improvement (all the flavors) and AI-driven workflows for small and large companies. Amit did a Computer Science degree at the University of Bath and moved from the UK to St. Louis, MO in 2014. He loves watching American robins and their nesting behaviors!

Follow Amit on his website, LinkedIn, Facebook, Reddit, X (Twitter) or YouTube.

Automate your workflows with Tallyfy

Stop chasing status updates. Track and automate your processes in one place.