10+ Process Improvement Examples to Drive Growth

Process improvement prioritizes effectiveness over efficiency because highly efficient processes may still fail to achieve business goals. Six Sigma targets 99.9966% quality through root cause analysis. LEAN manufacturing, pioneered by Toyota, eliminates waste based on customer value. Cross-training employees prevents bottlenecks from sick days and vacations, while regular employee surveys reveal hidden improvement opportunities they see daily.

Process improvement is about making things more effective, not just efficient. Here is how we approach process improvement.

Tallyfy is Process Improvement Made Easy

Summary

- Process improvement focuses on effectiveness, not just efficiency - Highly efficient processes may still fail to achieve business goals if they are not effective at delivering customer value

- Six Sigma targets near-perfect quality at 99.9966% - This methodology focuses on root cause analysis to eliminate defects, errors, and variations that reduce process effectiveness

- Cross-training prevents bottlenecks from sick days and vacations - People-centric processes are vulnerable to disruption when key employees are unavailable, making monthly training programs essential

- Regular employee surveys reveal hidden improvement opportunities - Workers directly involved in processes often know exactly where errors occur and what could be fixed, making their input more valuable than outside consultants. See how Tallyfy helps identify and reduce inefficiencies

A business process is directly defined as a string of activities within your organization typically performed by a group of people (though sometimes only one employee) with the aim of achieving specific goals or milestones.

Businesses often focus on trying to make these processes more efficient in order to save time and money, but it’s not efficiency that should be the primary focus. For any company to see positive growth and profit, the business processes it has in place needs to be effective.

I think we have to notice that the business processes we use right now for thinking and planning and budgeting and strategy are all delivered on very tight agendas.

— Margaret J. Wheatley (Source)

Any time processes are improved, they should be done so for the purpose of making them more effective. That’s the real goal. Because even highly efficient processes may not be effective.

Process improvement examples

There are a number of process improvement examples that show how steps could be taken in a business to make things more effective as well as efficient.

Cost Cutting - One process improvement example is in cutting costs. Through restructuring processes, organization, and visualization it is easy to spot redundancies and other items that wind up increasing overhead costs.

From there, unnecessary tasks are dropped. That restructure allows for resources to be reallocated so you spend less while your processes flow better.

Reducing Communication Issues - Another business process improvement example is the improvement of communication. Process improvement is intended to improve how things work by streamlining communication, such as decreasing the number of emails and contact touch points between departments and employees.

This is often achieved using software that allows employees and departments to see and share information - rather than chasing email threads through an inbox.

Process Visualization - With process modeling, it becomes far easier to audit and continually make improvements. Visualization allows you to follow the process and locate bottlenecks as they arise, or opportunities to make that process more efficient.

That auditing is one of the most critical parts of process improvement because every process you create needs to be monitored regularly. Without proper monitoring, you’re not really in control.

Types of process improvement

As businesses try to accelerate growth while running lean, there is always a desire to reduce costs through process improvement. Like the examples above, this could include:

- Improving product quality

- Upgrade service quality

- Improve delivery times

- Reduce billing cycles

- Make production more efficient

There are three terrific process improvement examples seen in larger organizations, even down into SMBs.

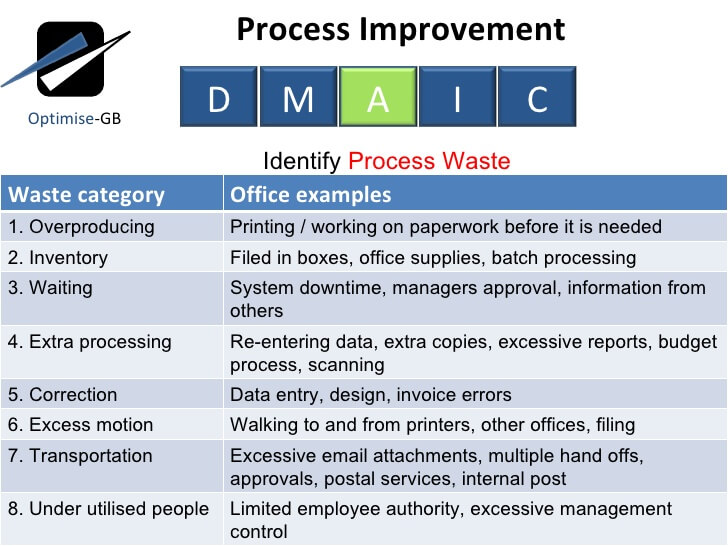

LEAN technology

LEAN Tech, also known as LEAN manufacturing, was a process that originated with Toyota. It was implemented to streamline the company’s production chain and dramatically reduce operating and overhead costs.

The key idea is to base process improvement on the customer perspective; taking the time to understand what they value from the product and then using LEAN process improvement to cut out unnecessary waste, errors and other things that drive up costs.

By focusing on value, the entire process is organized to drive more of what the customer is willing to pay for.

Six Sigma

Six Sigma is a process improvement example that focuses on achieving the maximum level of obtainable quality within an organization. At the Six Sigma level, that’s a rating of near 100% perfection (or 99.9966%).

The Six Sigma approach looks closely at the root cause of problems, defects, and variations that reduce the effectiveness of processes. At its heart, there’s a philosophy of constant improvement that’s in place to consistently and progressively improve results until that max level of perfection is achieved.

Top quality management

Six Sigma is a new process improvement example. The older approach, Total Quality Management, was crafted by W. Edwards Deming who was best known for the process improvements he brought to automotive manufacturing - particularly in Japan.

Like Sig Sigma, Total Quality Management focuses on the elimination of errors.

Concentrated improvement sprints

One approach that’s gained serious traction is running focused improvement workshops that compress what might take months of committee meetings into a single week of intensive work. You pull together the right people, clear their calendars completely, and spend five days doing nothing but dissecting one specific process problem. No distractions, no other meetings, just relentless focus on fixing something broken.

The psychology behind this matters more than the methodology. When people know they only have one week to show results, they stop debating and start doing. A legal services firm I spoke with ran a half-day session focused solely on their intake process - by lunch, they had mapped every delay point and assigned owners to fix them. Three months of “we should really look at this” solved before dinner.

One thing at a time beats batching

At Tallyfy, we’ve seen something counterintuitive that trips up most operations teams: processing work in batches feels efficient but usually isn’t. Moving one item completely through all stages before starting the next often beats accumulating piles at each step.

Think about invoice processing. The batch approach says collect fifty invoices, then approve them all, then code them all, then pay them all. Looks organized on paper. In practice, errors discovered late require rework on the entire batch. The one-at-a-time approach catches problems immediately - you fix one invoice completely before touching the next. Total throughput actually goes up because you’re not shuffling papers multiple times or tracking down context you’ve already forgotten. Manufacturing figured this out decades ago; knowledge work is still catching up.

Focusing on continuous process improvement

Process improvement is not a one-and-done affair. Well-run businesses focused on growth needs to maintain continuous improvement.

As those process improvements positively impact the bottom line, further investments in making operations more effective can be made.

Is improvement optional?

Are you hearing this at work? That's busywork

Enter between 1 and 150,000

Enter between 0.5 and 40

Enter between $10 and $1,000

Based on $30/hr x 4 hrs/wk

Your loss and waste is:

every week

What you are losing

Cash burned on busywork

per week in wasted wages

What you could have gained

160 extra hours could create:

per week in real and compounding value

Total cumulative impact over time (real cost + missed opportunities)

You are bleeding cash, annoying every employee and killing dreams.

It's a no-brainer

Some continuous process improvement examples include:

Ideation and think tank sessions

Companies should consider hosting regular ideation sessions, either open to all employees or strategically held to bring in key team members from each team or department. These sessions should also include key members of leadership.

This way all ideas and perspectives are considered when generating new ideas for workplace improvements.

Rather than have a free for all of the ideas, you might want to have an agenda or list of topics to discuss. Then each individual or team is given the opportunity to present possible solutions.

Time audits

One key approach to continuous improvement comes in auditing time. Set measurable benchmarks so you can track the time it takes to complete any specific job or task.

This is not done at the employee or even leadership level. Instead, a professional researcher observes the work that is performed and makes a record of the time needed to complete the task.

Once this data is recorded, a study can be run to examine the data and establish the standards by which that process or task should be completed in the future. While the primary focus should always be on the effectiveness of process improvements, you should still target task efficiency to better control the costs involved in the production.

Monthly training and cross training

Ongoing training is a smart choice for inclusion in ongoing process improvement. When you cross-train employees to work in multiple positions, you are protecting your processes from bottlenecks that occur as a natural result of people-centric processes.

Anything from a sick day to a vacation can have a negative impact on production.

Having trained staff that can rotate and fill a position helps to avoid any slowdown in production. For this reason, schedule monthly training programs that continually educate your staff.

Poll everyone

The people who work directly within your processes have the best insight into the root cause of errors, and where things could potentially be improved. From what I’ve seen across thousands of customer conversations, the savviest and watchful employees could likely give you a list, right now, of improvements that could be made. One consulting firm told us their biggest problem was steps being missed or done out of order. Within weeks of documenting their processes, they reported “fewer mistakes” because forcing themselves to write out the steps exposed gaps nobody had noticed.

Introduce surveys that go out to your vendors as well as your employees and stakeholders, each with unique questions, to help you understand the impact of your process improvement efforts. In my experience implementing feedback systems across our mid-market (55%) and enterprise (45%) customer base, organizations that survey regularly catch problems before they become crises.

The surveys can also provide a great deal of insight into things you did not even realize were a problem - or potential issue. There are some key questions your surveys should include:

- What are you doing that they believe to be satisfactory - how do you delight them?

- What could be done to improve the quality of products and services?

- What changes would they like to see in the future (let them prioritize what is most important to them.)

Take the data from those surveys, done at regular intervals, to score how your company operates, and how previous changes have (or have not) improved your processes.

Related questions

What is considered a process improvement?

It has been suggested that process improvement is akin to “your work methods getting a makeover”. It’s a matter of figuring out smarter, faster, cheaper ways of doing things.

Picture you are assembling deli sandwiches. If you rearrange your ingredients so that they’re more accessible, or find a shortcut for spreading butter, that’s process improvement. It’s all about adjusting the way we work in tiny ways to make life easier, save time or enhance quality.

Often it’s a small change, such as adding a new tool, and other times it’s a seismic shift, like completely reimagining the way a team can work together. From what I’ve seen across our mid-market and enterprise customer base, the small changes usually add up faster. A pharmaceutical company we worked with identified six specific problems with their existing approach - ownership gaps, missed reminders, unclear review processes, scattered email submissions, limited global collaborator access, and lack of real-time updates. Each small fix compounded into major improvement.

What are the four areas of process improvement?

Consider process improvement as a four-part puzzle. There are efficiencies, for one - making or using things more quickly or with less waste.

Second: quality - making sure our work is of the highest quality and error-free. Third is customer satisfaction - keeping our users (yes, all of us) happy and coming back for more. Finally, of course, is a need to save money - to save without cutting corners.

All four of these components work together in perfect harmony. We can, for instance, pay to become more efficient, and with more efficient systems often come higher quality, happier customers and reduced costs.

You’re killing four birds with one stone!

What is an example of a process improvement goal?

Let us say you own a pizza parlor. A good process improvement target could be: “Lower delivery time to 80% of prior time in 90 days without sacrificing any pizza.” This goal is specific (faster by 20%), measurable (we can time deliveries), achievable (it’s not asking the impossible), relevant (faster delivery makes customers happy), and time-bound (three months).

How might you do that? By changing the layout of your kitchen, by teaching your staff faster ways to make pizza, by optimizing your delivery routes. And here’s the beauty of this goal: It’s not just about going faster; it can also get you happier customers, lower costs and maybe even more orders.

It’s as if you gave a turbo boost to your entire pizza operation!

About the Author

Amit is the CEO of Tallyfy. He is a workflow expert and specializes in process automation and the next generation of business process management in the post-flowchart age. He has decades of consulting experience in task and workflow automation, continuous improvement (all the flavors) and AI-driven workflows for small and large companies. Amit did a Computer Science degree at the University of Bath and moved from the UK to St. Louis, MO in 2014. He loves watching American robins and their nesting behaviors!

Follow Amit on his website, LinkedIn, Facebook, Reddit, X (Twitter) or YouTube.

Automate your workflows with Tallyfy

Stop chasing status updates. Track and automate your processes in one place.