What is operational excellence?

Achieve peak performance across your operations

Summary

"Operational excellence isn't about perfect processes - it's about creating a culture where problems get fixed in days, not quarters."

- Shingo Institute Research

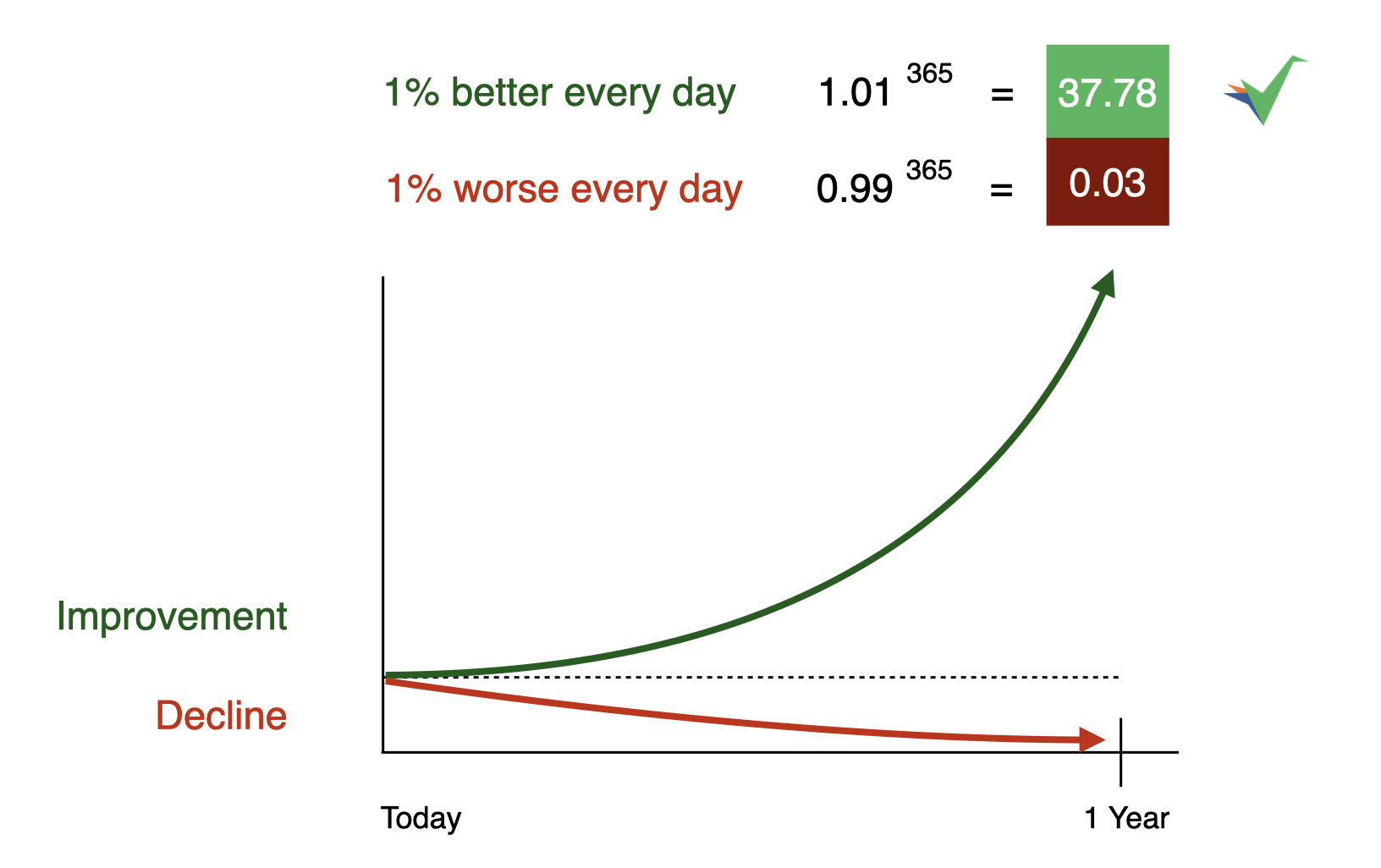

- Operational excellence is cultural, not procedural - Based on feedback from hundreds of operations teams, the breakthrough happens when every person can see how value flows and actively improves it daily through small, compounding changes - not just in annual workshops.

- 70% of operational excellence programs fail - McKinsey research found that most fail not because the theory is wrong, but because execution breaks down between perfect documentation and messy reality.

- Real results from operations teams: A compliance-focused services team achieved $1 million in Year 1 savings and 4x revenue growth by standardizing SOPs with proper version control. An investment operations team saved $150,000 annually while processing 500+ deals by eliminating manual paperwork tracking.

- The key metric that matters: Time from identifying a problem to implementing a solution. In our conversations with operations leaders, world-class teams fix simple issues in under a week. Most companies? Annual planning cycles.

- Ready to see operational excellence in action? Let us walk you through how modern teams make continuous improvement visible and measurable.

You spent three hours in that "process improvement" meeting. Everyone nodded. Charts were shown. And absolutely nothing changed.

Sound familiar? You are not alone - McKinsey found that 70% of operational excellence programs fail to achieve their goals. Not because the theory is wrong, but because the execution breaks down between perfect documentation and messy reality.

What is operational excellence? (The real answer)

Operational excellence is when every single person in your organization can see exactly how value flows - and actively improves it. Not once a year in a workshop. Every day, in small ways that compound.

Think of it like this: It's the difference between having a gym membership (process documentation) and actually being fit (operational excellence). One looks good on paper. The other delivers results.

Most people confuse operational excellence with process perfection. It's not. It's about creating a culture where a warehouse worker feels comfortable suggesting a better picking route, and that suggestion actually gets implemented within days, not months.

The truth about operational excellence vs continuous improvement

Here's what most guides won't tell you: continuous improvement is just doing things better. Operational excellence is knowing which things to do in the first place.

Continuous improvement focuses on incremental changes - making that 5-step approval process take 4 steps instead. Operational excellence asks whether you need approvals at all.

A mid-size manufacturing company in Ohio spent 18 months "continuously improving" their inventory management process. Reduced processing time by 40%. Impressive, right? Then they realized their customers would rather have smaller, more frequent deliveries. All that optimization? Wrong problem.

That's operational excellence - seeing the whole system, not just the parts.

The 10 core principles (with actual examples)

The Shingo Institute awards an annual prize for operational excellence. Here is what actually wins - not the theory, but how it plays out in real organizations. Based on our conversations with operations leaders implementing these principles, these are the patterns that separate success from failure:

Principle #1: Respect every individual

The Shingo Model says everyone has worth and potential. Fine. But what does that actually look like?

At a 300-person financial services firm in Dallas, "respect" meant the CEO started attending the weekly customer service huddle. Not to talk - to listen. Within two months, three major process bottlenecks were fixed because frontline staff finally had a voice. The fixes? Things like auto-populating forms that agents were typing 50 times a day. Simple stuff that saved 90 minutes per person daily.

Want to show respect? Stop scheduling process mapping sessions without the people who actually do the work.

Principle #2: Lead with humility

Leaders admitting they don't have all the answers. Sounds nice. Here's what it actually means.

A healthcare network in Phoenix had their Chief Medical Officer shadow nurses for a full week. Not observing - actually doing the documentation, dealing with the systems, experiencing the 14 different logins required for basic tasks. The result? They scrapped a million-dollar "digital transformation" project and instead spent $50,000 on single sign-on. Nurse overtime dropped 30% in three months.

Humility means experiencing the work before "fixing" it.

Principle #3: Seek perfection (but start with good enough)

Everyone says perfection is impossible. They're right. But that misses the point.

A credit union in Portland aimed for "perfect" member onboarding. Instead of building the ultimate process, they started with one question: "What makes members call us in the first week?" Answer: They couldn't find their account number.

Solution? Text it to them. Implementation time: 2 hours. Member calls dropped 40%.

That's seeking perfection - one specific problem at a time.

Principle #4: Embrace scientific thinking

This isn't about spreadsheets. It's about testing assumptions.

An e-commerce fulfillment center assumed faster picking meant better service. They tested it: Group A got standard 2-day shipping with accurate tracking. Group B got expedited picking but vague delivery windows. Customer satisfaction? Group A won by 20 points.

Scientific thinking means measuring what customers actually care about, not what you think they should care about.

Principle #5: Focus on the process

When the quarterly report is wrong, who gets blamed? The analyst who prepared it. But here's what actually happened at an accounting firm in Chicago:

The analyst had to pull data from seven different systems. Three required VPN access that expired randomly. Two had different fiscal calendar settings. One crashed if you exported more than 1000 rows. The process was broken, not the person.

They fixed the process with automated data pulls and standardized formats. Errors dropped 85%. Same analyst. Better process.

Principle #6: Assure quality at the source

Quality control catches defects. Quality at the source prevents them.

A medical device manufacturer was inspecting finished products and finding 3% defect rates. Acceptable? They didn't think so. Instead of adding more inspectors, they gave assembly workers the authority to stop the line if something felt wrong. Defects dropped to 0.3% within six months. Why? Workers knew the subtle signs - a screw that turned too easily, a click that didn't sound right.

Quality at the source means trusting the people doing the work.

Principle #7: Flow and pull value

Your customer needs something. How many stops does that request make before they get it?

A software company tracked a typical feature request: Customer to Support to Product Manager to Developer Meeting to Sprint Planning to Development to QA to Deployment Committee to Release. Timeline: 3-6 months.

They switched to: Customer to Product Team to Daily Deployment. Timeline: 1-2 weeks for simple features.

That's flow - removing the stops between need and delivery.

Principle #8: Think systematically

Marketing hits their lead targets. Sales misses quota. Success? Not if marketing is generating the wrong leads.

A B2B software company discovered their highest-converting leads came from specific LinkedIn posts, not their expensive Google Ads. But marketing was measured on lead volume, not quality. System thinking led them to measure marketing on qualified pipeline, not lead count. Revenue per marketing dollar increased 3x.

Systems thinking means optimizing for the whole, not the parts.

Principle #9: Create constancy of purpose

"We're customer-focused" is not a purpose. "We help small businesses process payments in under 2 seconds" is.

A regional bank had five different "strategic initiatives" running simultaneously. Employees couldn't explain what mattered most. They simplified to one purpose: "Make banking take less than 5 minutes." Every project, every process, every decision filtered through that lens. Customer acquisition costs dropped 40% because everyone knew what mattered.

Purpose isn't a poster. It's a filter for decisions.

Principle #10: Create value for the customer

A logistics company surveyed customers about delivery preferences. Everyone said "faster." So they invested millions in expedited shipping. Customer satisfaction stayed flat.

Deeper research revealed the truth: Customers didn't need faster delivery. They needed to know exactly when delivery would happen. The company added 30-minute delivery windows. Same speed, better information. Customer retention increased 25%.

Value isn't what you deliver. It's what customers actually want.

The three most effective methodologies (and when each actually works)

Methodology #1: Lean manufacturing - When you have repeatable processes

Lean works brilliantly when you're making the same thing repeatedly. Toyota assembles thousands of identical Camrys. Perfect for Lean.

But here's where it breaks: A marketing agency tried applying Lean to creative campaigns. They standardized their "ideation process" into seven mandatory steps. Creativity died. Clients left. Lean failed because creativity isn't manufacturing.

Use Lean when:

- You do the same thing more than 10 times per month - Repetition is where Lean shines

- Variation is your enemy - Manufacturing, fulfillment, standard services

- Quality means consistency - Customer expectations are predictable

Skip Lean when:

- Every project is unique - Creative work, custom consulting

- Innovation is your differentiator - R&D, product development

- Your value is customization - Bespoke services, luxury goods

The seven wastes Lean targets are real. But in knowledge work, the biggest waste isn't motion or inventory - it's killing ideas with process.

Methodology #2: Six Sigma - When variation is expensive

Six Sigma aims for 3.4 defects per million opportunities. Fantastic for heart surgery or airplane parts. Overkill for your monthly newsletter.

A pharmaceutical company saved $2 million annually using Six Sigma on their packaging line. A software startup spent $500,000 on Six Sigma training and consultants. Result? They moved 5% slower and lost their competitive edge. Why? In pharma, variation kills people. In startups, variation teaches you what customers want.

DMAIC (Define, Measure, Analyze, Improve, Control) works when:

- You have thousands of data points

- Small variations cause big problems

- The process is stable and won't change dramatically

A mid-size insurance company used DMAIC on claims processing. They had 10,000+ claims monthly - perfect for statistical analysis. Processing time dropped 30%. But when they tried applying it to their 50 monthly commercial underwriting decisions? The framework was heavier than the process itself.

Methodology #3: Kaizen - When you need cultural change

Kaizen means "change for the better." It's not a project. It's a mindset.

A furniture manufacturer in North Carolina implemented Kaizen. Not the version where consultants run a workshop. The version where anyone can submit an improvement idea on a simple form, and it gets tested within a week. First year: 847 ideas submitted, 312 implemented. Savings: $1.8 million. More importantly: Workers started caring because their ideas mattered.

The power isn't the methodology. It's the message: Everyone's ideas count.

Real-world operational excellence transformations

The theory is nice, but what does operational excellence actually look like in practice? Here are patterns we have observed across different industries:

A global hospitality management group operating 50+ hotels across 23 countries needed to standardize revenue operations and reservation procedures. Their challenge: every property was tracking bookings differently, making it impossible to understand where revenue was actually coming from. By implementing standardized market segment codes and guarantee policies across all properties, they achieved consistent revenue visibility and eliminated the confusion that came from each hotel using its own categorization system.

A large enterprise technology team running quarterly financial planning coordination was losing an estimated $7,500 per quarter (50 hours at $150/hour) just on one planning process - and that was before counting the knock-on effects to other teams. Their pain: "People were suffering with flowcharts, forms, and email coordination. Piles of emails causing confusion and delays." By making the 27-step quarterly process visible and trackable with clear handoffs, they eliminated the email ping-pong that was creating friction across regions.

A property management operation managing 3,500+ rental properties transformed from relying on memory with no formal tracking to standardized operations across their entire portfolio. The key insight: "Business continuity - someone else can pick up right where they left off." Field staff needed mobile access to processes, and the risk of human error, complacency, and inconsistency was affecting tenant relationships.

A payroll processing team reduced onboarding time from 14 days to 5 days per team - a 64% reduction. Their specific problem: "Lack of quality assurance controls over collected information" combined with multi-state tax compliance creating complex documentation requirements. Teams had frustrated people due to unclear processes and lengthy timelines.

Why traditional operational excellence fails (and what actually works)

Here's what nobody talks about at conferences: Most operational excellence programs are designed for the 1990s. Large manufacturers with stable processes and hierarchical structures. That's not your reality.

Your reality is:

- Remote teams across time zones

- Processes that change monthly, not annually

- Knowledge work that's different every time

- Five different collaboration tools that don't talk to each other

- Documentation that's outdated before it's published

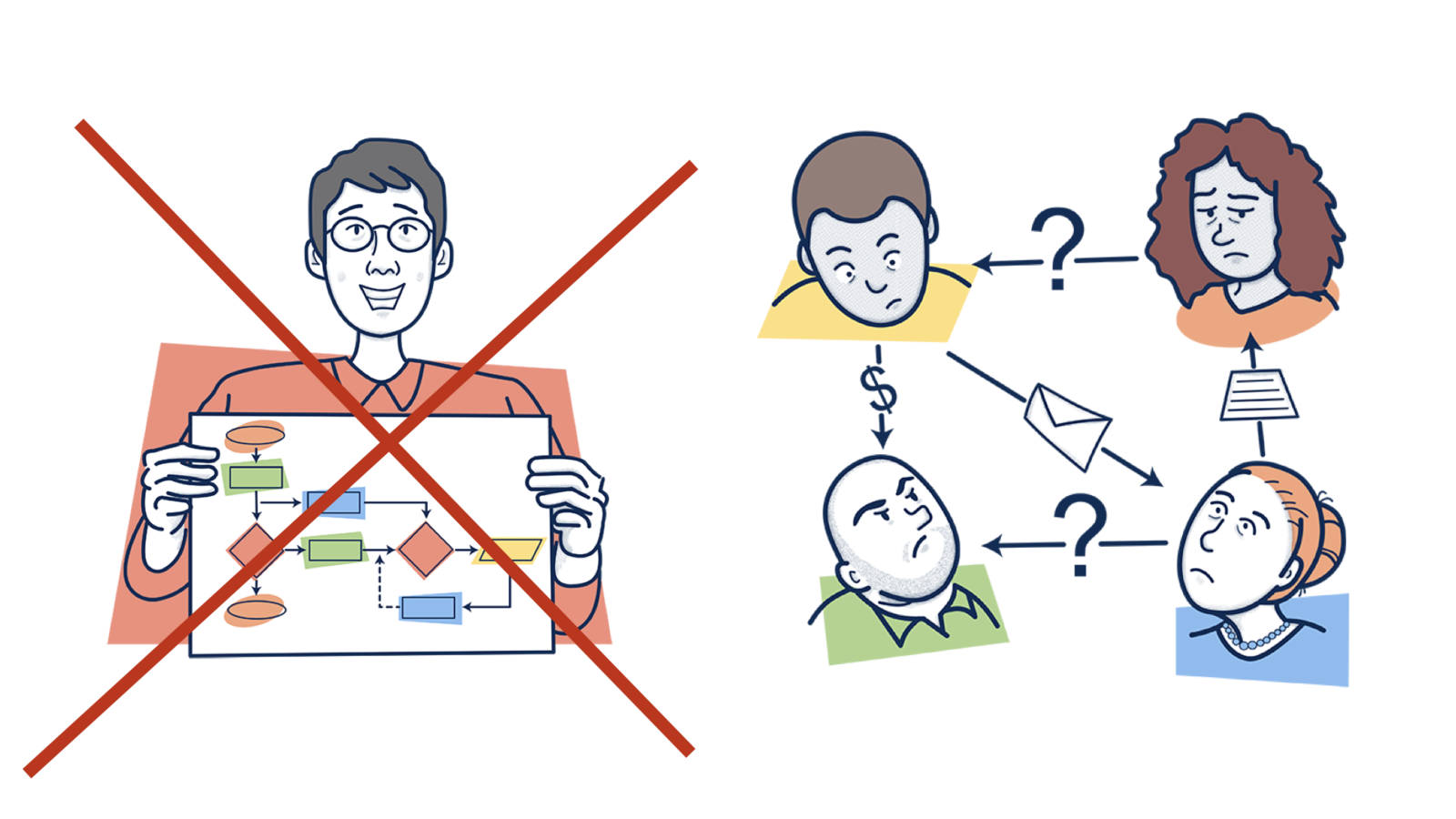

The problem with legacy BPM (Business Process Management)

Traditional BPM software promised to solve everything. Map your process in a flowchart. The system enforces it. Perfect processes forever. Here's what actually happened:

A financial services firm spent $3 million on a leading BPM platform. Two years later:

- 90% of processes were "exceptions" that bypassed the system

- IT spent more time maintaining the BPM than improving processes

- Users created shadow processes in Excel to get actual work done

- The vendor required $500,000 in consulting to make "simple" changes

Why? Because BPM was built for IT departments, not business users. It assumes processes are stable, predictable, and complicated. But most processes aren't complicated - they're just unclear. There's a difference.

What modern operational excellence looks like

Forget flowcharts. Think clarity.

Modern operational excellence is not about perfect processes. In our experience working with hundreds of operations teams, it is about visible workflows that actually get followed. Here is what works:

Visibility Over Documentation

- Everyone can see what's happening in real-time

- No more "what's the status?" emails

- Problems surface immediately, not in quarterly reviews

Automation Over Enforcement

- Routine tasks happen automatically

- People focus on decisions, not data entry

- The system adapts to how people actually work

Improvement Over Perfection

- Changes can be made in minutes, not months

- Every process has a feedback mechanism

- Small improvements compound daily

A 200-person professional services firm switched from traditional BPM to modern workflow automation. Results after 6 months:

- Client onboarding time: 5 days to 1 day

- Status update meetings: Eliminated (everything's visible)

- Process improvement ideas: 10x increase (because people could actually implement them)

- IT involvement: Zero after initial setup

This pattern repeats across industries. A government contractor managing ISO 9001 and CMMC certifications reduced pre-onboarding from 1-2 weeks down to 2-3 days (71-86% reduction) and cut onboarding from 5-7 days to 2-3 days (57-71% reduction). One HR person now efficiently manages 10-20 simultaneous onboardings, with 16 compliance workflows running automatically - eliminating manual tracking entirely.

Making operational excellence real (not theoretical)

Start here: The 30-minute reality check

Feedback we have received from operations teams is consistent: start with the process that annoys everyone. Not the most important. The most annoying. Maybe it is expense reports. Or requesting time off. Or getting marketing approval. Something that should take 5 minutes but takes 50.

Map the reality, not the theory:

- Who actually does what? (Not what the manual says)

- Where does it get stuck? (The real bottlenecks)

- What would "good enough" look like? (Not perfect)

- What's the smallest change that would help? (Start there)

A tech company did this with their laptop provisioning for new hires. Official process: 24 steps across 4 departments. Reality: IT guy named Steve did everything. Solution: Give Steve an assistant and a simple checklist. New hire Day 1 readiness went from 60% to 95%.

Templates to kickstart operational excellence

The power of making work visible

Work that is invisible cannot be improved. This is one of the most consistent patterns we see across implementations. A consulting firm made one change: Every project got a simple status board visible to everyone. Not complex project management. Just: Not Started, In Progress, Stuck, Done.

Results:

- "Stuck" items got unstuck 3x faster (people helped each other)

- Status meetings dropped 75% (everyone could see status)

- Client complaints about communication: Nearly eliminated

Building improvement into daily work

The best operational excellence programs don't feel like programs. They feel like Tuesday.

An accounting firm added one question to their daily standup: "What wasted your time yesterday?" Not to fix everything. Just to capture it. After a month, they had a heat map of inefficiency. Top annoyance? Hunting for client tax ID numbers. Solution? A simple searchable database. Time saved: 30 minutes per person per day.

That's 2.5 hours per week. 130 hours per year. Per person. From one question in a daily meeting.

The technology reality check

Everyone says "digital transformation" will solve everything. Here is the truth based on what we have seen across hundreds of implementations: Adding technology to a broken process just helps you fail faster.

But the right technology - simple, focused, adopted by actual users - changes everything. Modern workflow tools that anyone can set up in minutes, not months. Automation that handles the mundane so humans can handle the meaningful. Visibility that eliminates the constant checking and chasing.

Practical operational excellence for different industries

Healthcare: Where seconds save lives

A 400-bed hospital in Atlanta reduced ER wait times by 40% without adding staff. How? They stopped optimizing the wrong things.

Instead of faster triage (already pretty good), they focused on the dead time between steps. Patient sees nurse, waits. Nurse documents, patient waits. Doctor orders tests, patient waits. They added one role: Flow coordinator. Someone whose only job was to eliminate the waits between steps. No medical training required. Just someone watching for when room 3 was ready for the next step.

Manufacturing: Beyond Lean

A mid-size electronics manufacturer in Michigan was already "Lean." They'd eliminated waste, standardized work, implemented 5S. Margins were still shrinking.

The breakthrough? They stopped thinking like manufacturers and started thinking like a service company. Instead of just shipping products, they added usage monitoring. When a customer's machine showed declining performance, they proactively shipped replacement parts. Customer retention increased 40%. Same factory, same products, different excellence.

Financial services: Speed without sacrifice

A regional credit union competed with big banks offering instant loan decisions. Their process took 3-5 days. Instead of rushing to match the speed, they asked: "What do our members actually value?"

Turns out, members valued understanding over speed. The credit union created a "loan coach" role - someone who'd walk members through the process, explain decisions, and suggest improvements for next time. Loan volume increased 30%. Not by being faster, but by being better.

Professional services: The billable hour trap

A consulting firm realized their operational excellence problem wasn't efficiency - it was effectiveness. Junior consultants were incredibly efficient at billing hours. They were also burning out and leaving within 18 months.

The fix? They changed the metric from billable hours to client outcomes. Suddenly, automation was good (it freed up time for high-value work). Collaboration improved (sharing knowledge helped everyone deliver better outcomes). Employee retention increased 50%. Revenue per consultant increased 35%.

Common operational excellence myths (debunked)

Myth 1: "We need to map all our processes first"

A software company spent 6 months mapping 200+ processes. Beautiful flowcharts. Comprehensive documentation. Implementation success rate? 5%.

Meanwhile, their competitor picked their top 5 customer-touching processes and made them visible and trackable. Customer satisfaction increased 30% in 3 months. You don't need to map everything. You need to improve something.

Myth 2: "Operational excellence is for large companies"

A 12-person marketing agency implemented operational excellence principles. Not Six Sigma or elaborate frameworks. Just simple rules:

- Every project has a clear owner

- Every task has a deadline

- Every process has a feedback mechanism

Result? They doubled revenue without adding staff. Small companies have an advantage: They can actually change things.

Myth 3: "We need expensive consultants"

Consultants have their place. But the best operational excellence comes from inside. Your receptionist knows why customers get frustrated. Your warehouse workers know where time gets wasted. Your sales team knows which processes kill deals.

A distribution company saved $2 million using employee suggestions. Cost of the suggestion program? $50,000 in rewards and recognition. ROI: 40x.

Myth 4: "Technology will solve our process problems"

A law firm bought practice management software to improve efficiency. Lawyers ignored it. Paralegals worked around it. IT supported two systems (the new one and the Excel sheets everyone actually used).

Two years later, they started over. This time, they fixed the process first - standardized how cases moved through the firm. Then they found simple technology that supported that process. Adoption rate: 95%. Because the technology fit the work, not the other way around.

Measuring operational excellence (metrics that matter)

Traditional metrics vs reality metrics

What Most Companies Measure:

- Process cycle time

- Defect rates

- Compliance percentages

- Cost per transaction

What Actually Matters:

- How often do people bypass the process?

- How many "urgent" requests break the system?

- How long before new employees can work independently?

- How many customer complaints mention "process" or "system"?

A retail chain tracked elaborate inventory metrics. Turns out, the best predictor of customer satisfaction? How often employees said "let me check in the back." They simplified to one metric: Product availability on the floor. Everything else followed.

Leading vs lagging indicators

Revenue is a lagging indicator. By the time it drops, the problem happened months ago.

Leading indicators for operational excellence:

- Employee suggestion rate (engagement)

- Time to implement changes (agility)

- Process exception rate (reality vs theory)

- Customer effort score (not satisfaction)

A SaaS company tracked customer support tickets as a lagging indicator. They switched to tracking feature confusion in user testing - a leading indicator. They could fix problems before customers experienced them.

The only metric that matters

If you track one thing, track this: Time from identifying a problem to implementing a solution.

- World-class: Less than a week for simple fixes

- Good: Less than a month

- Average: Quarterly review cycles

- Poor: Annual planning processes

A logistics company averaged 6 months from problem identification to solution. They set a goal: 30 days for any customer-facing issue. They hit it by giving front-line managers authority to make changes without committee approval. Customer retention increased 20%.

The new approach: Incremental excellence

Start where you are

You don't need to transform everything. Start with one team, one process, one annoying problem that everyone wants fixed.

A marketing team started with one issue: Creative approvals took forever. They didn't redesign the entire creative process. They just added a simple rule: Feedback within 24 hours or it's approved. Campaigns launched 50% faster. One rule. Massive impact.

Build trust through quick wins

People don't believe in operational excellence because they've seen too many failed initiatives. Build trust with visible, quick improvements.

- First: Pick something broken that affects everyone

- Then: Fix it (good enough, not perfect)

- Next: Celebrate the fix publicly

- After that: Ask "what's next?"

An insurance company did this with parking. Silly? Maybe. But when employees saw that management fixed the parking situation in two weeks (after years of complaints), they started believing other changes were possible.

Make improvement everyone's job

Continuous improvement shouldn't be a department. It should be a reflex.

A manufacturing plant tried something radical: Every employee could spend $100 to fix something without approval. Only rule: Share what you did and why. First month: Chaos. Second month: Amazing ideas. Third month: Culture change. Workers started thinking like owners because they had owner-like authority.

The hidden costs of poor operational excellence

The talent drain

Your best people don't leave for money. They leave because they're tired of fighting broken processes to do good work.

A tech company surveyed exiting employees. Top reason for leaving wasn't compensation (ranked #4). It was "inefficient processes that prevented me from doing my best work." They lost 40% of their top performers over two years to operational friction. The cost of replacing them? 2x their annual salaries, plus the knowledge that walked out the door.

The innovation block

When people spend 60% of their time on process overhead, when do they innovate?

A product development team tracked their time. Results:

- 35% in status meetings

- 25% updating documentation

- 20% waiting for approvals

- 20% actual product development

They eliminated half the meetings, automated status updates, and gave teams approval authority up to $10,000. Innovation velocity doubled. Not because they hired more people or worked harder. They just removed the friction.

The customer experience gap

Your operational problems become your customer's problems.

A B2B software company had great products. And lost 30% of customers annually. Why? Onboarding took 6 weeks and involved 5 different people who didn't talk to each other. Customers got conflicting information, repeated themselves constantly, and started relationships frustrated.

They consolidated onboarding to one person with one clear process. Churn dropped to 15%. Same product. Better operations.

Related questions

What is operational excellence in simple terms?

Operational excellence is when your entire team can see exactly what needs to happen, when it needs to happen, and how to make it better - without meetings, emails, or confusion. Imagine if everyone just knew what to do next and had the power to fix what's broken. That's operational excellence. It's not about perfect processes on paper. It's about work that flows smoothly in reality.

What's the difference between operational excellence and continuous improvement?

Think of it this way: Continuous improvement is going to the gym regularly. Operational excellence is being actually fit. You can continuously improve the wrong things for years (like optimizing a process nobody needs). Operational excellence ensures you're improving what actually matters to customers. One is activity, the other is results.

What are the 4 pillars of operational excellence?

The real four pillars that matter are: People (engaged and empowered), Process (visible and adaptable), Technology (simple and adopted), and Culture (improvement is everyone's job). Traditional frameworks might list different pillars, but these are what actually work in practice. Miss any one, and the whole thing collapses.

How do you measure operational excellence?

Forget complex scorecards. Measure three things: How fast can you fix a customer problem? How often do employees suggest improvements? How many processes actually match reality? If problems get fixed in days not months, if everyone's contributing ideas, and if your documented processes match what people actually do - you're operationally excellent.

Why do most operational excellence programs fail?

They fail because they're designed for the wrong era. Traditional programs assume stable processes, hierarchical organizations, and plenty of time for implementation. Your reality is different - remote teams, constant change, and the need for speed. Most programs also focus on process perfection instead of process clarity. Perfect processes that nobody follows are worthless.

Can small businesses achieve operational excellence?

Small businesses have a massive advantage - they can actually change things quickly. A 20-person company can implement a process improvement by lunch. A 20,000-person company needs six committees and a steering group. Start small: Fix one annoying process that affects everyone. When people see it work, they'll want to fix more.

What's the first step toward operational excellence?

Stop documenting and start observing. Pick your most painful process and watch what actually happens. Not what the manual says - what people really do. You'll find the official process and reality diverged long ago. Fix the reality first, then update the documentation. Most companies do it backwards and wonder why nothing improves.

How long does it take to achieve operational excellence?

You can see meaningful improvements in 30 days if you start with something specific. A client onboarding process, expense approvals, whatever drives everyone crazy. Full organizational excellence takes 18-24 months of consistent effort. But here's the secret: You don't need to be perfect. You just need to be better than you were yesterday.

What role does leadership play in operational excellence?

Leaders set the tone, but they don't own excellence - everyone does. The best leaders do three things: Remove barriers that prevent improvement, celebrate wins publicly (especially small ones), and ask "what's broken?" more than "what's working?" When the CEO personally thanks someone for identifying a problem, the culture shifts overnight.

How is technology changing operational excellence?

Technology used to mean expensive enterprise systems that took years to implement. Now it means tools that anyone can set up in an afternoon. Modern workflow automation doesn't require IT degrees or consulting armies. It just requires clarity about what you want to achieve. The technology should be invisible - people just see their work flowing better.

What is the ROI of operational excellence?

Real companies see 20-40% productivity gains within the first year. According to Gartner research on operational excellence, the bigger ROI is in what does not happen: You do not lose your best people to frustration. You do not miss opportunities because you are too slow. You do not waste millions on the wrong improvements. A mid-size company saving 2 hours per person per day across 200 people? That is $3 million annually at average salaries.

Specific examples from operations teams: A legal team doubled the number of cases each attorney handles by replacing Excel spreadsheets with systematic process templates - eliminating the need for staff to memorize 100+ steps for estate proceedings. A media production team achieved $57,480/year savings through process automation while tripling revenue in 4 months. An investment firm saved $150,000 annually by avoiding operations hires while saving 5 hours per deal across 500+ investments.

How do you sustain operational excellence over time?

Make it part of daily work, not a separate initiative. Every meeting ends with "what could be better?" Every new hire asks "why do we do it this way?" Every complaint triggers a process review. When improvement is woven into regular work instead of special projects, it sustains itself.

What's the biggest misconception about operational excellence?

That it's about eliminating all variation and standardizing everything. That works for manufacturing widgets. It kills knowledge work. Modern operational excellence is about clarity and visibility, not rigid standardization. You want consistent outcomes, not identical processes. There's a difference.

How do you get employee buy-in for operational excellence?

Start by fixing something that annoys them, not something that annoys management. When employees see their suggestions implemented quickly, they'll suggest more. When they see real problems solved (like that printer that jams every Tuesday), they'll believe bigger changes are possible. Buy-in comes from visible action, not vision statements.

What is the connection between operational excellence and satisfaction?

Your operational chaos becomes someone else's problem. Every internal handoff that fails, every approval that delays, every process that confuses - people on the receiving end feel it. Fix your operations and satisfaction follows automatically. A company that reduced internal handoffs from 7 to 3 saw satisfaction scores increase 25% without changing anything else.

How do multi-location or global teams achieve operational excellence?

The challenge for distributed teams is that "processes existed in people's heads" - and those heads are spread across time zones. A hotel management group operating across 23 countries solved this by standardizing codes and procedures so every property tracked operations the same way. The key insight: you need to align systems (reservation, financial, property management) so they speak the same language. Without that standardization, you cannot compare performance across locations or identify where improvements are needed most.

What happens when work is scattered across multiple tools?

Tool sprawl kills operational excellence. Teams consistently report work scattered across Salesforce, Trello, Airtable, DocuSign, and email - with manual data entry causing duplicates and errors. A Dubai property management team running 400+ daily workflows found that paper-heavy renewal processes with missed steps were creating "unclear accountability." The fix was not another tool - it was consolidating processes into a single visible workflow that eliminated the sprawl. Processing times improved 75% once people stopped hunting through multiple systems.

The path forward: From theory to reality

Operational excellence is not achieved through massive transformation programs. It is built one improvement at a time, one team at a time, one day at a time.

Here is the truth based on what we have learned from hundreds of implementations: You do not need complex methodologies or expensive software. You need clarity about what matters, visibility into what is happening, and the ability to change things quickly when they are not working.

The companies winning at operational excellence are not the ones with perfect processes. They are the ones where a warehouse worker can suggest a better picking route on Monday and see it implemented by Friday. Where feedback leads to actual changes, not just reports. Where the time from "this is broken" to "it is fixed" is measured in days, not quarters.

Moving beyond traditional BPM

Remember that comparison table from earlier about legacy BPM versus modern approaches? The landscape has shifted dramatically. While traditional BPM platforms require massive IT investment and months of implementation, today's operational excellence is about getting started immediately with tools anyone can understand.

The old model - complex flowcharts, rigid processes, IT-owned systems - simply doesn't work for modern businesses. You need something that business users actually want to use. Something that makes their work easier, not harder. Something that can change as fast as your business does.

If you're curious how modern teams are achieving operational excellence without the complexity and cost of traditional BPM, it might be worth exploring how work can be made visible and trackable in minutes, not months. Where every process has built-in feedback loops for continuous improvement. Where tracking and scaling happen automatically, not through expensive consulting engagements.

The path to operational excellence doesn't have to be complex. Sometimes it's as simple as making work visible, trackable, and continuously improving - one process at a time. The question isn't whether you need operational excellence. It's whether you're ready to move beyond theory and into practice.

Ready to streamline your workflows?

See how Tallyfy makes workflow management simple and effective for teams of all sizes.

About the Author

Amit is the CEO of Tallyfy. He is a workflow expert and specializes in process automation and the next generation of business process management in the post-flowchart age. He has decades of consulting experience in task and workflow automation, continuous improvement (all the flavors) and AI-driven workflows for small and large companies. Amit did a Computer Science degree at the University of Bath and moved from the UK to St. Louis, MO in 2014. He loves watching American robins and their nesting behaviors!

Follow Amit on his website, LinkedIn, Facebook, Reddit, X (Twitter) or YouTube.