Continuous process improvement: definition and techniques

Continuous process improvement (CIP) is the ongoing effort to improve product, services or processes through incremental or breakthrough changes.

Summary

- Build improvement culture top-down - Start with C-suite encouraging management, which then trickles to shop-floor employees. Use systems like the Kaizen Corner where all employees submit suggestions in three stages: evaluate all ideas with clear reasoning, train employees on process analysis, and offer incentives for participation

- Balance incremental and breakthrough innovation - Frontline employees excel at finding minor process faults (incremental improvements), but you need a specialized team of engineers for breakthrough innovation that can make processes 2x more effective through technology adoption or complex solutions

- Map before you improve - Create business process flowcharts to understand the hows and whys of your processes. One six sigma team spent time streamlining information flows but did not question if the data was needed - once they did, they eliminated much of it and freed up thousands of hours for customer-facing work

- Ready to document your processes? See how Tallyfy makes process improvement systematic

Continuous process improvement (CPI) ensures that your business survives and strives in the long-term. By constantly re-evaluating and improving business processes, your organization will be more efficient, innovative and agile.

If you look at all the big or successful companies today, you will rarely find one that does not audit and analyzes their processes or products systematically.

What is continuous process improvement (CPI)?

By definition, Continuous process improvement (CPI) is the act of implementing improvements to a product, service or process. These changes can either be incremental (over time) or breakthrough (all at once).

The key here is continuous - CPI isn’t a one-time initiative. You don’t just optimize a certain process once, pat yourself on the back, and call it a day. Once you succeed with a process improvement initiative, you need to periodically look back and see whether there are any changes you could make. Think, adopting new hardware, software, methodology, etc.

If you are familiar with other process management terms, you might be a bit confused where CPI stands. Here’s how it’s different from other methodologies…

Business Process Improvement (BPI) - As the name suggests, BPI is the act of improving a process. Continuous process improvement involves carrying out a BPI initiative whenever it is needed.

Business Process Management (BPM) - BPM is a methodology that helps you manage processes. While Continuous process improvement is an essential part of BPM, a company that does CPI doesn’t necessarily employ BPM.

Kaizen - Kaizen is more related to company culture rather than process improvement. It involves building a culture of innovation and contribution, which allows for continuous process improvement.

If you want to make CPI a systematic part of how your organization operates, dedicated software can help you track improvements, gather feedback from frontline employees, and ensure changes actually stick.

Tallyfy is Process Improvement Made Easy

Continuous process improvement (CPI) techniques

Enforcing continuous process improvement in your company is up to you. You will need to ensure that your employees are motivated enough to carry out BPI initiatives (we will explain how to do that in a bit). To help you with actually improving processes, you can use one of the many continuous improvement tools…

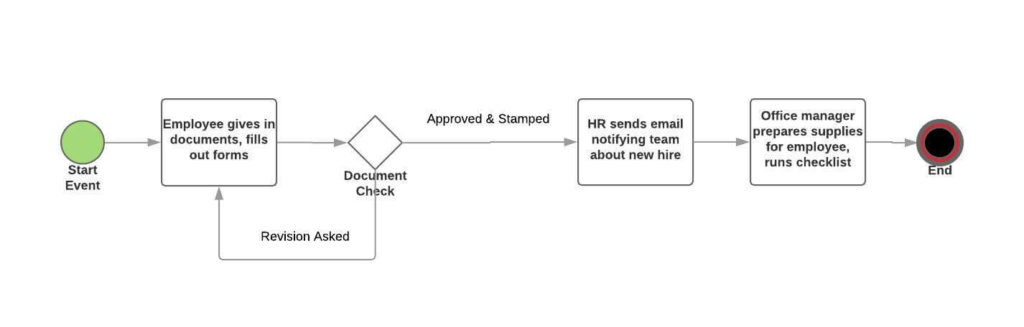

Business process mapping

Chances are, you don’t really know every one of your business processes by heart. To get a better idea of the hows and whys of the process you are working on, you will need to create a business process map. The simplest way is to create a flowchart including different process steps. So, for example, here is a process map for employee onboarding…

Process templates you can improve continuously

For creating the map, you have three options…

- Pen & Paper - The easiest way is to just grab a piece of paper and draw the flowchart.

- Flowchart Software - Dedicated software for creating process maps. The benefit here is that you can share it with your employees digitally.

Once you have a process map, you can use the Deming Cycle technique to improve the process.

Still not sure how, exactly, process mapping works? We don’t blame you, creating a process map isn’t that easy. Read up our guide to learn the exact steps you need to take in order to successfully map your business processes.

Deming cycle (PDCA)

The Deming Cycle, also known as PDCA, is a concept introduced by Dr. Edwards Deming. There are 4 steps to it…

- Plan - Identifying a goal or purpose, formulating a theory, defining success metrics, and putting a plan into action

- Do - Implementing the plan on a small scale to prove or disprove its validity

- Check - Measuring and monitoring outcomes to test the validity of the plan. This allows for identification of potential problems and areas for improvement

- Act - Taking the knowledge gained from the previous steps and putting it to use. This can either mean implementing it on a wider scale or restart the cycle and apply the lessons learned to change the plan for the better

Want to learn more about the Deming Cycle? Read up our complete guide to PDCA

Process management software

Once you make improvements to a process, you need to make sure that they stick. Business Process Management Software (BPMS) allows you to do that and more. You can also gather feedback for improvement from the people doing the work.

You can create a digital process and the software will take care of its execution. At Tallyfy, we’ve seen that instead of having to manually notify employees of process changes, you simply update it within the system and they get automatically notified.

In addition, BPMS automatically routes tasks between your employees, making sure that everyone gets the job done.

Want to learn more about how the software works? Check out our guide to different BPM solutions.

Creating the culture for continuous process improvement (CPI)

If you, the manager, personally lead every single process improvement initiative, you aren’t likely to make any lasting change. More often than not, it’s the employee that knows how to work with the process best, not their supervisor. In our conversations with COOs at healthcare non-profits and professional services firms, we have heard this confirmed repeatedly - one organization managing volunteer onboarding told us that when they started tracking their 60-day member onboarding process properly, they saw a 50% improvement in member retention simply because frontline staff could now identify and intervene when people were falling behind. You want to empower them with the tools and ability to carry out process improvement when need be.

The key to establishing a culture of continuous process improvement is to make it a part of company culture. It should start top-down from the organization - the C-suite should encourage the management to make suggestions on process improvement. This, in turn, will trickle down from the management to shop-floor employees.

As a given, there should be a system that rewards initiative. Anyone that contributes an idea or two (whether it’s implemented or not) should be encouraged and rewarded.

An example of a system you can use is the “Kaizen Corner.” It’s a place where all of your employees can go and hand in suggestions on how to improve processes. This usually works in three stages…

-

Everyone’s suggestions and considered and evaluated. The employees are made aware of the reasoning for accepting certain suggestions and rejecting others. This helps show your team that their input is valued, whether their suggestions are implemented or not.

-

To ensure that the employees do a better job in the long-term, you hold training on process analysis.

-

Offer different incentives for employees to help with process improvement. This can be in the form of bonus pay, physical gifts, etc.

Once you have got the culture down, you should also consider creating a special team for breakthrough innovation. Your average employees are great at helping with incremental innovations - finding minor faults in the process and proposing suggestions.

For breakthrough innovation, you’ll probably need a more specialized team consisting of engineers. There will be times when adopting new technology, for example, could make a process 2x more effective. A team of specialists will help find such situations and create more complex solutions.

Process consultant and author Ron Ashkenas describes the need for and benefits of this type of balance:

Question whether processes should be improved, eliminated, or disrupted. … For example, a six sigma team in one global consumer products firm spent a great deal of time streamlining information flows between headquarters and the field sales force, but did not question how the information was ultimately used. Once they did, they were able to eliminate much of the data and free up thousands of hours that were redeployed to customer-facing activities.

A combination of incremental and breakthrough innovation will ensure that your company is as efficient as it could be, giving you an edge over any competition.

Ready to make continuous improvement systematic in your organization? See how Tallyfy helps teams document, track, and improve their processes.

Related questions

What are the 5 steps of the continuous improvement process

The improvement itself is based on a simple but powerful five-step cycle. First thing is to recognize the problem or opportunity.

Second, assess our current situation and collect data. Third, generate solutions and pick the best one. Step 4 - Pilot The preferred solution is tried in a small scale.

Finish by testing your results and tweaking as necessary. This cycle, while it is commonly referred to as the PDCA (Plan-Do-Check-Act) cycle, can be used as a means for organizations to continuously improve and march steadily towards its goals.

What are the 5 key principles of continuous improvement

The foundation of continuous improvement is five underlying principles that shape an organization’s endeavors towards excellence. The first of these is customer obsession, which means always pushing to exceed what customers expect.

Second is employee involvement, the belief that workers themselves often know better than management how to make things better. Third is process-based thinking (seeing the organization as a system of processes). Then there is data-driven decision making, which can help you to base your decisions on what is known rather than what is assumed.

And finally, continuous learning and iteration, a love for change and a welcome of failure as a chance to evolve.

What is the approach to continuous process improvement

Continuous process improvement is about taking small steps over time. Rather than looking for an explosive, overnight change, this method is championing small, incremental ones.

It engages all employees, from front-line labor to levers at the top, in identifying and applying improvements. This methodology is supportive of experimentation, learning from failure, and acknowledging success. Organizations can realize substantial long-term benefits in efficiency, quality, and customer satisfaction by making improvement a daily habit.

What are the 3 phases of the continuous improvement process

The improvement effort is broken down by the three primary phases of the continuous process of improvement. Phase 1: Planning In this phase, problems are identified, goals are established, and “blueprints” of possible solutions are created.

The execution phase is the second phase, which consists of carrying out the selected improvements and collecting data. The third phase is reflect, in which results are reviewed, lessons are drawn, and the cycle commences again. These phases generate a cycle of continuous improvement, meaning businesses never become stagnant and instead continue to develop and adjust in response to emerging challenges or opportunities.

What are the benefits of continuous process improvement

Ongoing improving your offers so many advantages to company. Doing so contributes to operational efficiencies, with unnecessary steps removed and alternate workflows used.

The earlier you catch and fix errors, the better the quality. And because products and services improve, customer satisfaction increases. Employee engagement increases when employees are empowered to create positive change.

Companies are more flexible and resilient, better able to cope with changes in the market. And, as importantly, that CI leads to a culture of innovation where creative problem solving is simply part of the DNA.

What to look for when choosing a continuous process improvement tool

A number of important factors are important for end users considering a tool for continuous process improvement. Seek intuitive interfaces to drive broad adoption throughout your company.

Look for solutions that are equipped with advanced data analytics features that can empower you to make data-driven decisions. Features for collaboration are also critical, as they provide teams the ability to work together more easily. Being able to see processes diagrammed out by flow charts or pictures can be very beneficial.

Interoperation with the existing systems is important to ensure smooth external introductions. Lastly, think about solutions that can be customized to meet your specific requirements and easily scaled to match the development of your business.

About the Author

Amit is the CEO of Tallyfy. He is a workflow expert and specializes in process automation and the next generation of business process management in the post-flowchart age. He has decades of consulting experience in task and workflow automation, continuous improvement (all the flavors) and AI-driven workflows for small and large companies. Amit did a Computer Science degree at the University of Bath and moved from the UK to St. Louis, MO in 2014. He loves watching American robins and their nesting behaviors!

Follow Amit on his website, LinkedIn, Facebook, Reddit, X (Twitter) or YouTube.

Automate your workflows with Tallyfy

Stop chasing status updates. Track and automate your processes in one place.