How to write a standard operating procedure in simple steps

If your organization is experiencing a lot of growth, you will need to start coming up with procedures to make sure the new employees do their job right. The best way to do this is by writing and implementing standard operating procedures. Here is how to do that in 5 easy steps.

Well-written SOPs reduce training time and ensure consistency.

SOP Management Made Easy

Summary

- SOPs solve two critical problems - Documentation onboards new employees faster by giving them step-by-step guidance, while enforcing best practices ensures every team member follows the most efficient variation of a process, not their own improvised approach

- Scope definition prevents document bloat - When processes span multiple departments, create separate SOPs for each team; marketing doesn’t need to know the writer’s workflow, and vice versa, keeping documentation focused and usable

- Three documentation options serve different needs - Basic checklists work for simple linear tasks, workflow diagrams handle complex processes with multiple decision points, while business process management software adds real-time tracking and bottleneck identification

- Metrics enable continuous improvement - You can’t improve what you don’t measure; defining process metrics (product output, leads generated, cycle time) reveals streamlining opportunities, automation potential, and outsourcing candidates. See how Tallyfy improves processes

Procedures are essential for making your business as efficient as possible. Your business already has processes - they are the repeatable work your employees do every day.

Think, approving an invoice, fulfilling orders, etc. A Standard Operating Procedure (SOP) is, on the other hand, the documentation of the process. It helps establish things like what are the different steps, what is the scope, who is in charge, etc.

Workflow automation is at the core of what we discuss with organizations at Tallyfy, with employee onboarding alone appearing in over 300 of our customer conversations. In our experience helping teams document their processes, SOPs are helpful for 2 things…

- Onboarding employees - It’s hard to remember the exact step-by-step of every process. Documentation makes it easy for your employee to get up to speed on how to execute processes

- Enforcing best practices - There is always an instance of a process that is more efficient than the others. You can establish this process as the “best practice” with a standard operating procedure, making sure that all of your employees follow the best variation of the process.

Both of these benefits can have a significant impact on your business, making the work of your employees more efficient.

In our experience helping teams document their processes, I have seen SOPs transform operations dramatically. One services company we spoke with went from 65+ employees down to 15 - not through layoffs, but by using SOPs for OSHA compliance and eliminating redundant and outdated tasks from their operations. The SOPs revealed that much of what they were doing was unnecessary duplication across four execution levels within the organization.

Now, you are probably wondering - where do I start? Well, in this guide, we are going to explain…

- What sections to include in your standard operating procedure

- How to create standard operating procedure documents (in 5 simple steps!)

- How to map and document your business processes

- How and why document your SOPs using business process management software

How to write a standard operating procedure in 5 steps

Before we dive into the nits and grits of how to write an SOP, you should have a good idea of what the document includes. Of course, this depends on your specific business needs (making the document meet ISO-9000), for example. Usually, though, the SOP would include…

- Title page - This can include the name of the process, the name of the department that the SOP applies to, etc.

- Table of contents - If the document is too long, you can always make a table of contents to make it easier to navigate.

- The procedure(s)

- Scope - Some processes can span different departments, teams, etc. To make sure you don’t make the SOP document overcomplicated, specify the scope of the procedure you are documenting.

- Terminology - Define any complicated term. Think, abbreviations, acronyms, etc.

- The procedure - Process documentation, map, etc.

- Supplementary information - This can be just about anything, depending on the process. For example, Information on the machinery and equipment (where is what), health and safety warnings, etc.

- Metrics - Being able to measure process efficiency is always useful. By defining the metrics in your SOP, you can always check back on whether the process is efficient over time. If, for example, you discover that a process is not as efficient as usual, there might be something wrong with the machinery.

Most of the information we have mentioned is pretty explanatory. You don’t need to be a rocket scientist to create a title page, table of contents, etc. Documenting the procedure, however, can be hard for someone that is not skilled at process management. Here is how to do it right…

Gather the team

Before you can even document the process, you will need to pinpoint all the important information. Chances are, you are not the one who carries out the process on a daily basis.

While you may have a good general idea of what the process consists of, you probably don’t know all the small details that can really affect the outcome. So, to really get the procedure down correctly, you need to consult with the employees that do it on a regular basis. Set up a meeting and call all the relevant employees.

Ask them to take you through the process step-by-step, explaining every little detail.

Define the scope

Sometimes, processes are interconnected. They can span different teams, departments, etc. If you start documenting the process without really defining the scope, the end result might end up being too long and complicated. From what I’ve seen, this is where most SOP projects fall apart. For a real-life example, we can look at our procedure for publishing content…

- The writer creates a draft of a blog post

- The editor reviews it and gives feedback

- The process is looped until the article is ready to be published

- The editor uploads the article on WordPress and optimizes it for SEO

- The marketing team gather relevant contact information for backlink outreach

- The marketing team send out emails for outreach

Depending on what the purpose of the Standard Operating Procedure is, you would probably divide the process into 2 parts. The writing team really do not need to know what the marketing team does for steps 5 and 6, and vice versa. If you are hiring a new writer, they only need to know steps 1 through 4, while marketers would need 5 and 6. So, depending on which department you need the SOP for, you would limit the scope accordingly.

Documenting the procedure

This is the bulk work of writing a standard operating procedure - actually creating the documentation.

The most basic option here is using a checklist or SOP template. This tends to look less like a SOP and more like a grocery list.

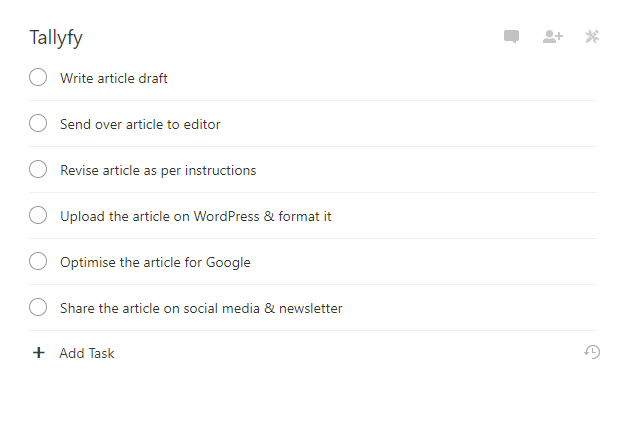

Basic publishing process checklist using Todoist

You write down the exact tasks needed to be completed for the process to be successful. Then, you either print it out and keep it at the office or publish it somewhere online for your employees to use as a reference.

Checklists, however, are very limiting. For more complex processes, you have different events and outcomes, so you cannot really fit all that into a simple to-do list. In that case, you would want to use a workflow diagram.

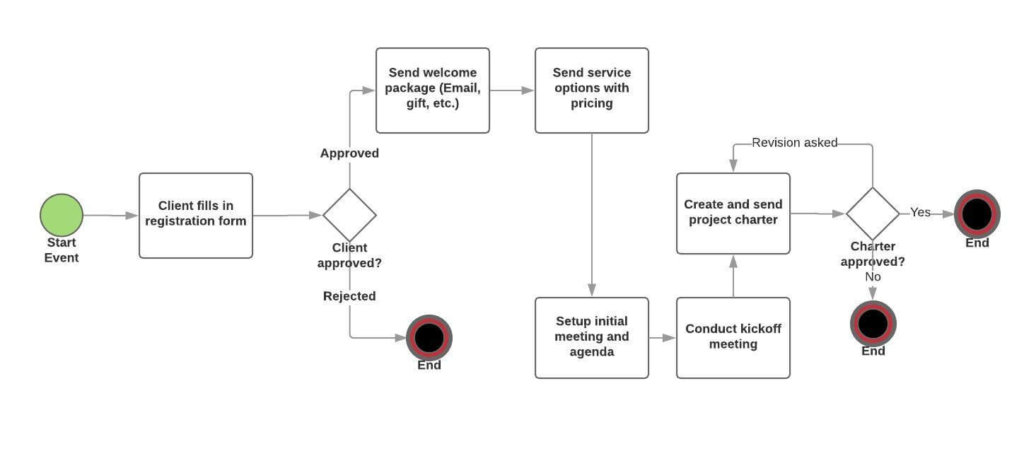

Client onboarding procedure flowchart

The gist of it is, you create a flowchart (or any other flow diagram) that details the different steps of the process, as seen in the example above. The simplest option here is a process flowchart, but you can also go for other map types, such as a Swimlane Diagram or SIPOC.

Finally, you can also use business process management software. Instead of creating a physical (or online) process map, you can use the software to do it digitally. This has several added benefits as opposed to the conventional options.

You can, for example, also use the software to keep track of the procedure online. Rather than having to check on your employee whether they are doing their job right or not, all you have to do is look at the dashboard.

The software lets you know of any problems that might come up - missed deadlines, bottlenecks, etc. That visibility matters. As a result, your processes become much more efficient.

Feedback we have received suggests this digital approach works especially well for regulated industries. A lab testing company we worked with needed SOPs for sample handling procedures with complete traceability for compliance requirements. Their pain point was “managing lab testing service processes with accuracy” - the digital SOP became both their training tool and their audit trail simultaneously.

List relevant information

In most cases, simply looking at a process flowchart is not enough to give you all the information about how to carry out the procedure. You might, for example, need to know where a certain piece of equipment is located.

Or, you might need to know the login credentials for some online software. Hence, you should list out any information that is necessary to finish the process. This can be things like…

- Methodology - What is the right way of carrying out a process step? This can be just about anything. For example, let us say you are onboarding a new employee. The process step could be “input employee information to HR software.” The additional information would be the type of information - name, last name, date of birth, etc.

- Necessary tools - If you need to use certain tools to complete a process step, you should mention how to do that. For example, “use machinery in room 201” or “use madeupcrmsite.com and use the credentials provided at randomlink.com”

- Health and safety warnings - If the procedure can be hazardous to someone’s health, you mention that in the SOP, as well as any necessary precautions needed for working on the process.

Define metrics, improve the process and update the SOP

At this point, you have already got the standard operating procedure down. At this point, you can call it a day, skip this step and start implementing the SOP.

You might have, however, realized that there are several potential improvements you could make to the process. This is pretty standard. Most organizations don’t look back at their processes after defining them, having a “don’t fix what isn’t broken” attitude.

More often than not, though, there are a lot of benefits to be gained from improving the process. First, you need to define the right metrics.

You can’t really improve something you can’t measure. For manufacturing, it could be product output. For marketing, leads generated per month.

Then, you can try using either one of the following process improvement techniques…

- Streamline the process - Are there any steps within the process that are taking too much time or resources? Is there any way to cut them out or replace them?

- Process automation - Is there any way to automate certain parts of the process? Most of the time, this can be done with software. You could, for example, automate customer support with Intercom Auto Messages.

- Process outsourcing - Are certain parts of the process grunt work? If it is something just about anyone can do, you could outsource it to a Virtual Assistant through UpWork.

Is writing SOPs enough?

Are you hearing this at work? That's busywork

Enter between 1 and 150,000

Enter between 0.5 and 40

Enter between $10 and $1,000

Based on $30/hr x 4 hrs/wk

Your loss and waste is:

every week

What you are losing

Cash burned on busywork

per week in wasted wages

What you could have gained

160 extra hours could create:

per week in real and compounding value

Total cumulative impact over time (real cost + missed opportunities)

You are bleeding cash, annoying every employee and killing dreams.

It's a no-brainer

Implementing the SOP

First off, congrats! At this point, you know everything on how to make a standard operating procedure.

Your work, however, isn’t done just yet. You need to implement the SOP. Meaning, you should make it easily accessible for all of your employees.

The best option here is to make it online. You either put the document on your favorite file-sharing software like Google Docs, or use process management software like Tallyfy if you are going digital.

As a given, all of your key employees should have access to either software. Or if you are more old-fashioned, you can always just print out the document and distribute it around the office. It is usually also a good idea to keep a few extra copies lying around, in case someone needs to find the SOP document in case of an emergency.

Start with proven SOP templates

Standard operating procedure for requesting purchases. Covers when approval is needed, spending limits by role, preferred vendors, and how to submit requests. Following this process ensures purchases are tracked and budgets are not exceeded.

View templateRelated questions

Why are standard operating procedures important?

SOPs are the safety net and roadmap for any enterprise. They stop them making mistakes and save time, and enable new people to learn fast. Consider them a recipe book for your business - they ensure that everyone cooks the dish the same way every time. SOPs also help protect your business when key people leave because their knowledge is already documented.

What is an example of an SOP?

Coffee Shop Example One obvious example is the method a coffee shop uses to make a latte. The SOP would contain each step: heating the milk to exactly 150 degrees F, pulling the espresso shot for 25-30 seconds, pouring the milk in a particular way. Another example is the routine for opening a retail store - say unlocking the doors, counting money in the cash register, and turning on lights and booting up computers - in that order.

How long should an SOP be?

An SOP should be as long as it needs to be to make the process transparent, but not a word longer. The best SOPs are 2-5 pages, although some complex procedures will require longer. The trick is to divide information into small pieces that are easy to swallow. Think of it as giving someone directions - you need enough information to prevent wrong turns, but not so much that the person ends up lost in the instructions.

What are the must-have elements of an SOP?

All good SOPs are complete with a descriptive title, purpose statement, scope of use, checklist of materials needed, step-by-step instructions and history of changes. If this were a recipe, you would think of all of the components as your list of ingredients and your cooking instructions; together, they give you all the information you need.

Should SOPs include pictures or diagrams?

Visual supports can increase the effectiveness of SOPs, and this is especially true for tasks that are complex. Just as assembly instructions with pictures and diagrams often present what would be difficult to put into words alone … so too listing images, as long as they do not “stand alone.” PC-only screenshots for PC tasks, flowcharts for decision-making and photographs for physical actions can also prevent confusion and accelerate the learning curve.

How often should SOPs be updated?

SOPs should be reviewed annually, at a minimum, though updates may be in order more often if processes, equipment or problems have changed. Think of it like you would updating the apps on your phone - if you update them regularly, they help keep the whole system running cleanly and patch any bugs that emerge.

Who should write the SOP?

The best people to write SOPs are a team that includes the people who do the work and the people who supervise it. Just as a cookbook can benefit from the curated experience of both chefs and home cooks, SOPs profit from diverse viewpoints. Managers might overlook key details that the people in the job every day are aware of.

What is the difference between an SOP and a work instruction?

SOPs generally deal with processes at a high level, possibly in multiple departments, while work instructions are the nitty gritty pieces of getting something specific done. Think of the SOP as a view of the entire trip, and work instructions as navigational instructions for each stop along the way.

How do you test an SOP before implementation?

New SOPs need to be trialed by asking someone not familiar with the task to follow them verbatim. It is similar to getting a friend to proofread your writing - she will catch things you missed, because you are way too close to the work. This dry run also helps to find any ambiguous or omitted instructions.

Can SOPs be too detailed?

Yes, details can make SOPs difficult to follow and hard to keep up with. The trick is to hit the right balance between too vague and too specific. As in a good story, the richness is in the detail; they illustrate the point far more convincingly than a simple statistic. Do not go so overboard that you lose readers in a sea of irrelevant information, but do not scrimp, either.

About the Author

Amit is the CEO of Tallyfy. He is a workflow expert and specializes in process automation and the next generation of business process management in the post-flowchart age. He has decades of consulting experience in task and workflow automation, continuous improvement (all the flavors) and AI-driven workflows for small and large companies. Amit did a Computer Science degree at the University of Bath and moved from the UK to St. Louis, MO in 2014. He loves watching American robins and their nesting behaviors!

Follow Amit on his website, LinkedIn, Facebook, Reddit, X (Twitter) or YouTube.

Automate your workflows with Tallyfy

Stop chasing status updates. Track and automate your processes in one place.