Total Quality Management is an approach that covers everything your business does, whether it’s for an external client or an internal one. Since that sounds pretty vague, we’re going to dive in and explaining how to use it for your organization.

Total Quality Management (TQM) Definition

TQM is an approach to quality in which every person in an organization is tasked with contributing to process, product, and service improvement and quality control. It becomes part of the working culture of the organization and contributes to continuous improvement.

Like most definitions, this one says quite a lot in just a few words. But what are the guiding principles you need to consider when implementing TQM in your business?

1. The Customer Has the Final Say

Isn’t it frustrating when you invest tons of time or money into improving quality, and your customer shrugs and says: “So what?” All the same, we know that the customer is always right (even when we might think he or she is wrong). The start and end point of any total quality management initiative is the internal or external customer.

Essentially, you need to walk a mile in your customer’s moccasins. See the customer experience from the customer point of view. No matter how much we tell our clients that they ought to be pleased with what we do, they’ll still make up their own minds as to whether they’re happy or not.

Remember Coca Cola’s new recipe? The company thought they were onto a big improvement, but in the end, it was the customers who decided – and they wanted Classic Coke. The moral of the story? It doesn’t matter if you think you’ve made an improvement. Your customers have the final say.

2. Every Employee Involved

Every employee becomes a quality controller and has a voice in the company’s ongoing drive towards ever-greater excellence. There’s no such thing as going home at the end of the workday to bluster about the way management could be doing things better.

Instead, every employee feels safe and comfortable with reporting issues and making suggestions for improvement. And they get feedback on what management has decided and credit where credit is due.

From the floor sweeper to the general manager, every single employee is quality focused. There are eyes and ears everywhere, and people at the coalface can discuss the quality issues they face in their daily work without being seen as complainers and bring suggestions without being seen as pushy.

This can make the company significantly more efficient – the management might not have that good of a look at company processes. The field-employees, however, live and breath their work, so it shouldn’t be that surprising that they have an idea or two on how to improve things.

3. It’s Process-Focused

A strong business is built on solid, standardized processes. Total Quality Management means looking for ways to improve and tighten up and improve business processes for greater efficiency and a better-quality result. It may mean developing new ways of working, new standards to govern work, or even complete restructuring of processes. However, the goal remains clear: business process improvement that targets customer satisfaction and quality.

4. Integrated Throughout the Organization

To deliver the best results, Total Quality Management should be embedded into every part of the organization. The horizontal interfaces between departments and teams are of particular interest. Smoother, more economical, and more effective process flows mean greater efficiency and greater customer satisfaction.

5. Continuous Improvement

Total Quality Management is not a once-off or periodic drive. It becomes part of a business culture in which every staff member contributes to continuous improvement. Who better to look at ways of improving the sales process than the people who do the job day in and day out every day?

Who better to suggest production improvements than the people who are engaged in the production process? Small improvements could have big results.

Continues improvement also implies lifelong learning. Relevant training that can help employees to perform their functions better is part of the deal.

7. Based on Performance Facts

TQM employs real data to make decisions. And following the principle of continuous improvement requires real-life data on which management can make decisions and measure results. That means gathering and analyzing data and then acting on any inefficiencies or quality problems you spot.

The more comprehensive your data-gathering, the more likely you are to see the full picture. For example, if you’re producing an unacceptably high percentage of faulty products, where does the problem lie? The more data you have on the processes that are leading to these results, the more likely you are to be able to target the problem area quickly and effectively.

Total Quality Management Tools

While TQM seems to be something extremely beneficial for any business, it isn’t that easy to implement. It’s one thing to say, “let’s make our organization process & improvement focus” and another to thing to actually do it.

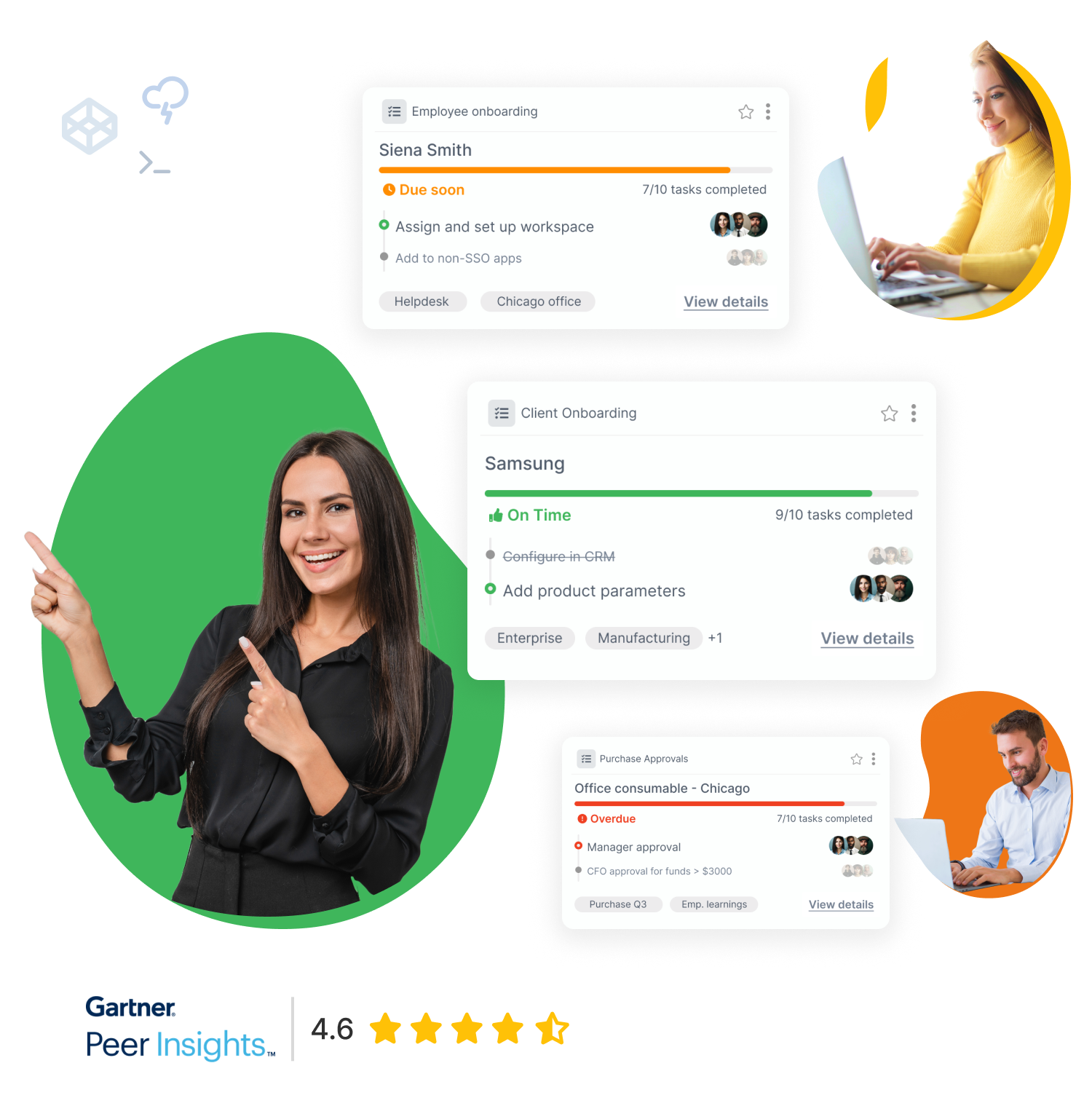

Using the right tools, however, can make this much easier. Workflow management software allows you to digitize and track your business processes, making process improvement accessible to an organization of any size.

Learn more about how Tallyfy can help your business take advantage of TQM by scheduling a free consultation.

Related Questions

What are the 4 principles of total quality management?

Total Quality Management Evaluation of the Four Principles TQM is based on four general principles; customer-centred, continuous improvement, employee participation, and data-driven decision making. These pillars help create a culture of excellence in which every part of an organization is focused on great quality. When organizations put the customers first, improving processes repeatedly, enabling people to take ownership and making data-driven decisions, they can accomplish amazing results and lead from the front in the competitive environment today.

What are the 5 elements of total quality management?

TQM focuses on five key areas: Customer-centric, leadership, process, engagement, and improvement. When put together, these elements create a powerful structure that reshapes organizations from the inside out. Companies that make every decision carefully, lead smartly, invest in processes, include all employees from the top to bottom of the hierarchy, and refuse to rest on their laurels feel alive; quality is an innate trait, and there is room for improvement and progress every step of the way.

What are the 8 principles of TQM?

But the 8 principles of TQM are the key ideas taken further: customer focus, leadership, engagement of people, process approach, system approach to management, continual improvement, factual approach to decision making and mutually beneficial supplier relationships. This broader set of principles creates a broader brushstroke of how organizations can stitch in quality through every fiber of their fabric. These principles serve as a guide for building a company that can pursue quality, from developing partnership relationships with suppliers to recognizing the whole company as a unified system.

Why is TQM important?

TQM is important because it changes the way organizations do things, resulting in better products and services, higher customer satisfaction, and improved competitiveness. By encouraging a culture of quality, TQM can help companies minimize errors, reduce costs, and increase efficiency. It also empowers employees which ignites innovation and creativity. TQM provides organizations the necessary tools to thrive and differentiate in a fast-paced, worldwide marketplace. It’s not only about better products but also better businesses.

What Does Total Quality Management Do?

Total Quality Management as an Accelerating agent It transforms company culture, tuning every process, decision and action to the pursuit of better quality. TQM eliminates silos, promoting an end-to-end ownership of quality and collective responsibility in organization. It enables employees at all levels to take responsibility and pride in their work as quality champions. Finally, by promoting data-driven decision-making, Total Quality Management helps organizations understand areas of needed improvement and measure progress, creating a cycle of continuous improvement that leads to lasting success.

How Does Total Quality Management (TQM) Work?

TQM is about blending quality-centered processing in every area of a business. It begins at the leadership level and pervades to all levels of the entity, building a collective vision of excellence. TQM utilizes an array of tools and methods to identify and eradicate inefficiencies, including statistical process control, Six Sigma, and lean manufacturing. This creates an environment where everyone takes ownership of quality, by encourages open communication, teamwork and problem-solving. TQM facilitates an organization in making data-driven decisions and measuring the success of initiatives through continuous data collection and analysis.

What are the challenges of Total Quality Management?

Implementing TQM can be challenging. Some common hurdles include resistance to change, lack of leadership commitment, difficulty in measuring intangible improvements, and maintaining momentum over time. Organizations may struggle to balance short-term goals with long-term quality initiatives. Another challenge is ensuring that TQM principles are applied consistently across all departments and levels. Additionally, in today’s fast-paced business environment, companies may find it tough to dedicate the time and resources needed for comprehensive TQM implementation. Overcoming these challenges requires patience, persistence, and a genuine commitment to the TQM philosophy.

Can TQM be applied to any type of organization?

Yes, the principles of TQM have been widely considered from a variety of types of organizations including, manufacturing firms, service to non profit to government agencies. Although TQM started in the field of Manufacturing, its fundamental principles, which include customer focus, continuous improvement, and employee involvement, are applicable anywhere. The point is to contextualize TQM to the unique needs and dynamics of the organization. A hospital could have strong emphasis on patient satisfaction and safety, a software company could care more about bug-free code and user experience. The generalizability of approach helps TQM to enhance the quality of goods and services gotten from different areas and businesses.