How to Solve Any Problem With Root Cause Analysis?

Uncover the secrets of effective problem-solving with root cause analysis. Learn proven techniques to prevent recurring issues.

Root cause analysis leads to process improvements that need to be implemented and tracked systematically.

Tallyfy is Process Improvement Made Easy

Summary

- One root cause solves multiple problems - Hospital found 17 reasons for wrong-surgery patient, all stemming from single organizational change need, not seventeen different fixes

- Five Whys reveals process fixes - Keep asking “why” until you identify the specific process requiring adjustment, like driver pre-trip oil check routine becoming mandatory

- 80/20 Pareto principle focuses efforts - 20% of possible causes create 80% of problems, so prioritize resources on highest-impact root causes instead of addressing every minor issue

- Tallyfy enables real-time monitoring - Track revised process implementation immediately without leaving your desk, responding quickly when problems arise. Need help identifying process bottlenecks?

Have you ever had a seemingly unsolvable problem? Sure, you have!

Your business is going all out trying to reach a specific goal or target, but you fall short. Someone says the equipment is to blame. So, you buy better equipment, but the problem persists.

Then, your management team suggests that it is human error, so you dive in with training interventions and performance appraisals. But the problem does not go away.

What you need to do is identify the “root cause” of the problem, the less-than-obvious reason why you are not reaching your goals. If your Root Cause Analysis can find it, you can correct it, stop throwing time and money at it, quit putting out fires, and enjoy the success with which your hard work deserves to be rewarded. By eliminating the root cause of an issue, you can prevent it from happening again.

Ever. Sounds worthwhile?

Let’s see how you would go about doing your Root Cause Analysis as a problem-solving tool.

Many symptoms can have a single cause

Before you even begin, it’s worth noting that you’re going to dig really deep and that by doing so, you could solve multiple problems at once. A single root cause can use can have multiple effects.

As an analogy, think of an illness. It will have several symptoms. If you only treat the symptoms, you have not addressed the cause, and the illness will not go away.

In the business context, solving a single root cause could solve several problems at once. For example, a root cause analysis on why a hospital patient received heart surgery intended for someone else found no fewer than seventeen reasons for why it happened.

The root cause was the need for organizational change. Things like quality issues, late deliveries, and missed targets could all come down to one, single cause. That is the “root” you are looking for.

If you want to weed out problems, just skimming the surface will give you a temporary solution. Remove the problems by the roots, and it’s gone forever.

Root cause analysis: three steps to root cause identification

Root Cause Analysis-based problem solving uses six simple-sounding steps. In practice, navigating them is more easily said than done, but the systematic approach will eventually lead you to that sneaky root cause that’s giving you so many grey hairs. Let’s unpack them:

1. Define the problem

Now, you might think it’s easy to define a problem, but it requires careful thought and possibly a little investigation to get a proper definition. For instance, you could say: “We have an unacceptable number of product defects.” That’s not a good definition.

How many defects are slipping through? What are those defects? What is the effect of the defect or defects?

Returning to the illness analogy, think about a visit to the doctor. You tell your doctor you have got a headache.

Before the doctor starts examining you, he or she will try to get more information about the headache. When did it start? Which part of your head hurts?

Are there any other symptoms that could be related to the problem? What is your medical history?

The more the doctor knows about your ailment, the easier it is to find out what’s causing it. Spend time analyzing the problem so that you can define it in as detailed a way as possible. Don’t start looking for causes yet.

That comes later.

2. What are the reasons for the problem?

Reasons are not the same thing as root causes. They are just the obvious issues which you may already have tried to address.

In some instances, you might end up with several reasons why something went wrong. That is fine. You need the full list.

Confused? Aren’t reasons root causes?

No, they are not! In our experience with workflow automation, we often see teams list five or six “reasons” for process failures - but when we dig deeper with the Five Whys technique, those reasons all trace back to one or two root causes. Here is a simple example. You have a runny nose.

What is the reason for the runny nose? The mucous membranes are inflamed.

If you are an allergy sufferer, you will know that the inflammation is not the root cause of your runny nose. A deeper cause would be an inappropriate response from your immune system, but that is still not the root cause. The real root cause is your exposure to an allergen.

So, you can identify reasons for a problem, but just trying to deal with reasons still will not eliminate the real cause of the problem you defined. You are making progress with your Root Cause Analysis, but you are not there yet.

List all the reasons you found and move to the next step.

3. Root cause identification

There are several tools that you can use to get under the skin of your problem and down to its root cause. Expect to take more time on this step than you needed for the steps you completed so far.

But it’s worth being thorough. Finding a secondary cause might not give you the root cause. Your Root Cause Analysis team has to dig and keep digging until they hit the bedrock of the issue.

Eliminating problems forever is a tantalizing prospect, so Root Cause Analysis is a very popular approach to problem-solving. Over the years, various tools have been developed to help businesses to identify root causes.

The tool you choose will depend on how complex your problem is, how big your business is, and the amount of time and resources you are willing to expend on problem-solving. Here are a few examples of popular Root Cause Analysis Tools:

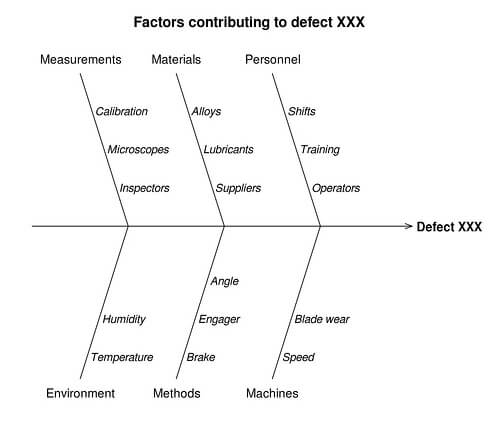

1. Fishbone diagrams

The Fishbone Diagram is a popular Root Cause Analysis Tool - and yes, it looks like a fish! Phrase the problem as a “why” question and place it at the head of the diagram.

The Fishbone Diagram is a popular Root Cause Analysis Tool - and yes, it looks like a fish! Phrase the problem as a “why” question and place it at the head of the diagram.

Now track possible causes using the Fishbone Diagram categories most relevant to your industry type. There are several variations, and it is up to you to decide which ones are the most likely to apply to your problem. Fishbone diagrams will help you to determine contributing factors that led to an issue.

But they may not immediately point to a process-based solution. To get there, try combining your fishbone diagram with the Five Whys.

2. The 5 Whys

The 5 Whys should point to a process that needs adjusting. Will you get there with just five questions?

You might not. Keep asking “why” questions till you reach a point where you can identify the process you need to adjust. Here is an example:

- Why could the vehicle not complete the journey?

The car broke down

- Why did the car break down?

The engine seized.

- Why did the engine seize?

There was not enough oil.

- Why was there not enough oil?

It was not topped up in time.

- Why was the oil not topped in time?

The driver did not check the oil before leaving. Note that the final “why” points to a root cause.

The driver didn’t check the oil. To ensure that this doesn’t happen again, the oil check needs to become part of the routine the driver follows. Simple fix, huge impact. Even this simple example points to a situation in which you have a chance to eliminate multiple problems.

Does the driver have a pre-trip checklist? What about checking tires and radiator water, and what about making sure that lights and indicators work?

3. Pareto analysis

The Pareto Analysis is based on the 80/20 principle. Try it out.

It works for both positive and negative results. Who buys 80 percent of your products? You will probably find that 20 percent of your clients give you 80 percent of your sales.

What causes 80 percent of your problems? Chances are you will find that 20 percent of the possible causes were responsible for 80 percent of them.

You may want to address ALL the possible causes of a problem, but overkill is costly. Use Pareto analysis to determine what your priorities are and where your resources should go.

How to address the root cause you identified and solve your problem

Now that you’ve zoomed in on the real reason why you have a problem, it’s time to do some problem-solving: three more steps, and you’ve arrived!

1. Design a solution

When working on solutions, keep your Root Cause Analysis aim in view. You don’t just want to solve the immediate problem.

You want to prevent the same problem from recurring. Here is a simple example. You have figured out that all the defective products come down to a poorly-maintained piece of production-line equipment.

Just calling in a maintenance crew is not good enough. How will you make sure that maintenance schedules are followed in future?

What symptoms would indicate that the equipment is due for routine maintenance? Who will be responsible for checking whether maintenance should be moved forward? What do they do, and what is their routine?

Do you notice the repetition of “routine”? That is what you want to create: a situation in which the problem is prevented as a matter of routine.

In other words, your solution becomes part of a repeatable process that is performed the same way over and over again. Also, consider whether the changes you plan to make will impact other areas of your business. Changes to processes can have knock-on effects.

Be sure you are not setting yourself up for a new set of problems when you implement the solution. To do this, you need to look at your process flows and how they relate to one another.

Simple example: you decide that your in-house maintenance team must check production-line equipment daily. Do they have the capacity to do this? Will they neglect other tasks if they need to do the daily check?

Should you outsource a task they performed before you reached your conclusion? Beware of overkill.

You probably don’t want duplication slipping in just because you want to be extra-sure of eliminating the root cause of an issue. The final part of the solution design process is to decide on checks and balances that will tell you whether your business is implementing the solution you have devised and whether it works as planned.

2. Implement the solution

Implementation means change, and change must be carefully managed. Everyone concerned needs to know about your solution and the reasoning that led you to believe that you can solve the problem.

So, explain the Root Cause Analysis process and how you arrived at your conclusion. Explain your solution and how you want it to be implemented. Ensure that everyone involved has the knowledge and resources they need to follow through and set a D-Day for testing your new system.

Keep in mind, though, that it is always better to first apply the solution on a small scale. You can never know what could go wrong.

Once you are certain that the new solution brings results, you can start applying it company-wide.

3. Evaluate the results

You are nearly there! Now, you need to know whether you hit the nail on the head.

When you designed the solution, you decided on key indicators that would allow you to see whether the solution works. Use these indicators to follow up. In this instance, you are going to see whether the symptoms are gone.

The presence or absence of the issues that launched you on your Root Cause Analysis and problem-solving initiative will tell you whether you have successfully solved the problem. Remember to watch out for new issues that may arise elsewhere as a result of the changes you made.

4. Software tools for root cause analysis, implementing solutions, and evaluation of solutions

Although the software will never have the flexibility of the human mind, it can do a lot of the legwork for you. If you are using business process management software like Tallyfy, you can use its analytics to pinpoint your problem areas, especially if they are time-related.

At what point did the process start going awry? In other words, you can use it to help you with the all-important first step of defining your problem. When performing your root cause analysis, Tallyfy will help you to identify bottlenecks and delays in the processes related to the problem you defined.

These could be reasons for the problem rather than root causes, but if you follow the root cause analysis process through, you can figure out why they are happening. Once you have identified a solution to your problem (remember, a solution is related to a process), you can start work on the changes you want to make.

Perhaps you discovered that solving your problem requires the elimination of a step in a business process. Simply go to the platform and remove the step. Now, when your employees run the process, the software ignores the step you removed, and the redundant step is out of the equation forever.

But how is your solution working? With Tallyfy, you can follow the implementation of your revised process and look for problems without ever leaving your desk.

Based on hundreds of implementations, we have observed that organizations using real-time process monitoring identify recurring problems 40-60% faster than those relying on periodic reviews. Best of all, it happens in real time, so you can respond quickly and decisively if problems arise.

Templates for tracking and resolving issues

Does root cause analysis work in problem-solving?

There is no arguing it: if you can identify the real root cause of a problem, you can solve it. Examples of successful problem-solving with Root Cause Analysis abound.

Boeing managed to improve its safety record. Wind power company, Clipper managed to solve its wind turbine issues using Root Cause Analysis. The list goes on.

However, obstacles to problem-solving using Root Cause Analysis do exist. The biggest culprits are:

- Failing to define the problem comprehensively.

- Failing to identify the real root cause.

- Poorly-designed or short-short sighted solutions.

- Insufficient attention to implementing and evaluating solutions.

Should you try problem-solving with Root Cause Analysis? Yes! Put on your thinking-cap, mobilize your team, and get to work! Will it not be wonderful when you can feel secure in the knowledge that the problems your business faces now will never rear their ugly heads again?

Do you know the root cause?

Are you hearing this at work? That's busywork

Enter between 1 and 150,000

Enter between 0.5 and 40

Enter between $10 and $1,000

Based on $30/hr x 4 hrs/wk

Your loss and waste is:

every week

What you are losing

Cash burned on busywork

per week in wasted wages

What you could have gained

160 extra hours could create:

per week in real and compounding value

Total cumulative impact over time (real cost + missed opportunities)

You are bleeding cash, annoying every employee and killing dreams.

It's a no-brainer

About the Author

Amit is the CEO of Tallyfy. He is a workflow expert and specializes in process automation and the next generation of business process management in the post-flowchart age. He has decades of consulting experience in task and workflow automation, continuous improvement (all the flavors) and AI-driven workflows for small and large companies. Amit did a Computer Science degree at the University of Bath and moved from the UK to St. Louis, MO in 2014. He loves watching American robins and their nesting behaviors!

Follow Amit on his website, LinkedIn, Facebook, Reddit, X (Twitter) or YouTube.

Automate your workflows with Tallyfy

Stop chasing status updates. Track and automate your processes in one place.