7 Basic Quality Tools for Process and Product Improvement

The 7 basic quality tools are graphical techniques used for troubleshooting issues related to product or process quality.

The 7 basic quality tools drive improvements that need to be tracked and measured with process improvement software.

Tallyfy is Process Improvement Made Easy

Summary

- Seven graphical techniques identify quality issues - Kaoru Ishikawa, University of Tokyo engineering professor, developed these tools for controlling and managing quality in any organization, fixing product and process problems visually

- Each tool serves distinct analysis purposes - Flow charts map complex processes to find commonalities, histograms measure distributions between variables, cause-and-effect diagrams reveal root causes, check sheets organize data, scatter diagrams show variable relationships, control charts monitor stability and predictability, Pareto charts prioritize biggest impacts

- Visual problem-solving works across all fields - Break down complex processes, understand root causes of daily business problems, analyze relationships between values, monitor performance, and determine which parameters matter most. See how Tallyfy improves business processes

The 7 quality tools were first conceptualized by Kaoru Ishikawa, a professor of engineering at the University of Tokyo. In our conversations with operations leaders across manufacturing, aviation, and professional services, these tools come up repeatedly when discussing quality improvement initiatives. They can be used for controlling and managing quality in any organization.

The 7 basic quality tools are, essentially, graphical techniques used to identify & fix issues related to product or process quality.

7 basic quality tools: the complete list

The 7 basic quality tools are as follows:

- Flow Chart

- Histogram

- Cause-and-Effect Diagram

- Check Sheet

- Scatter Diagram

- Control Charts

- Pareto Charts

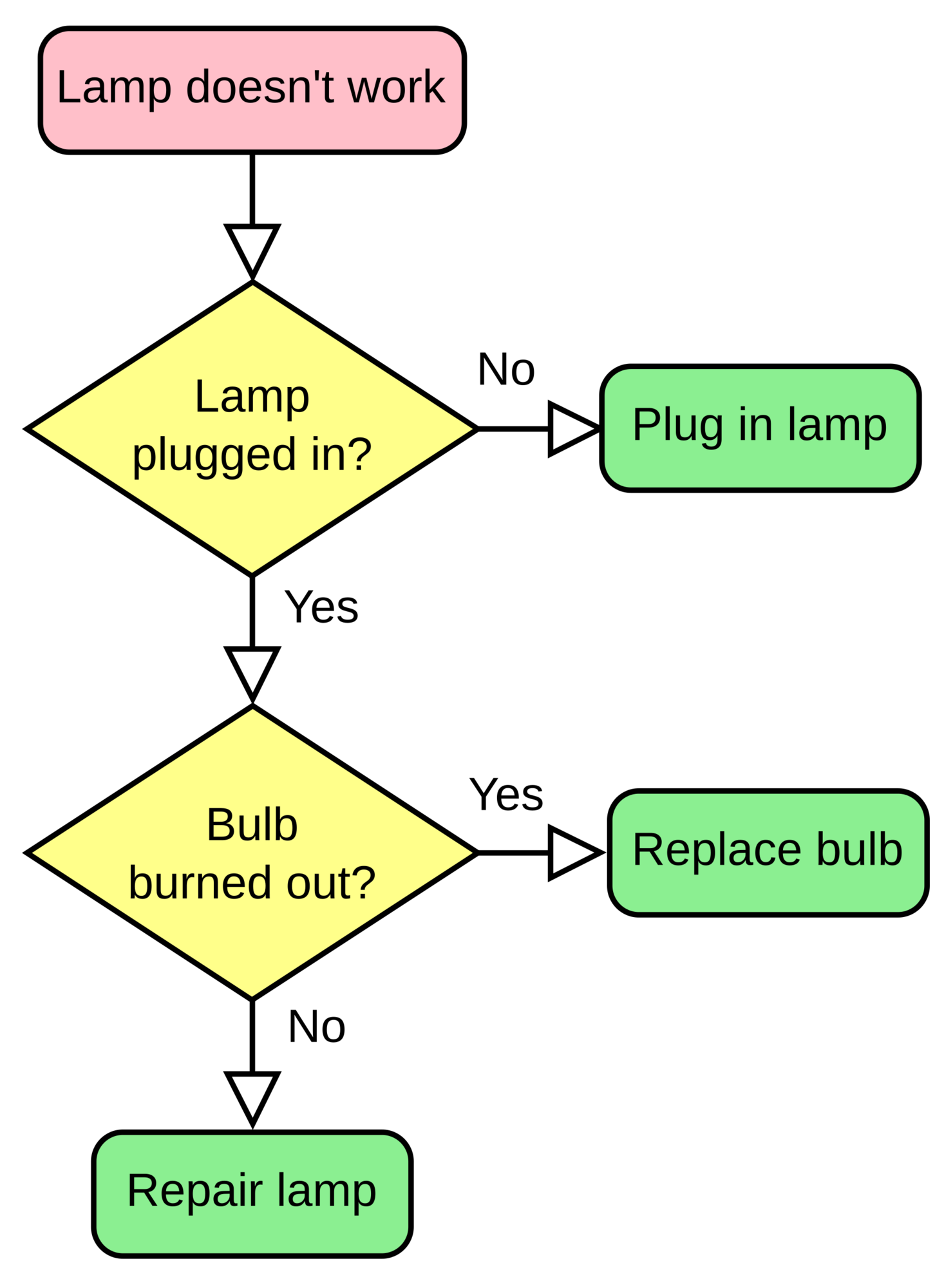

Flow charts: Flow charts are one of the best process improvement tools you can use to analyze a series of events. They map out these events to illustrate a complex process in order to find any commonalities among the events.

They are also one of the most common methods of creating a workflow diagram.

Flow charts can be used in any field to break down complex processes in a way that is easy to understand. You can then go through the business processes one by one, identifying areas for improvement.

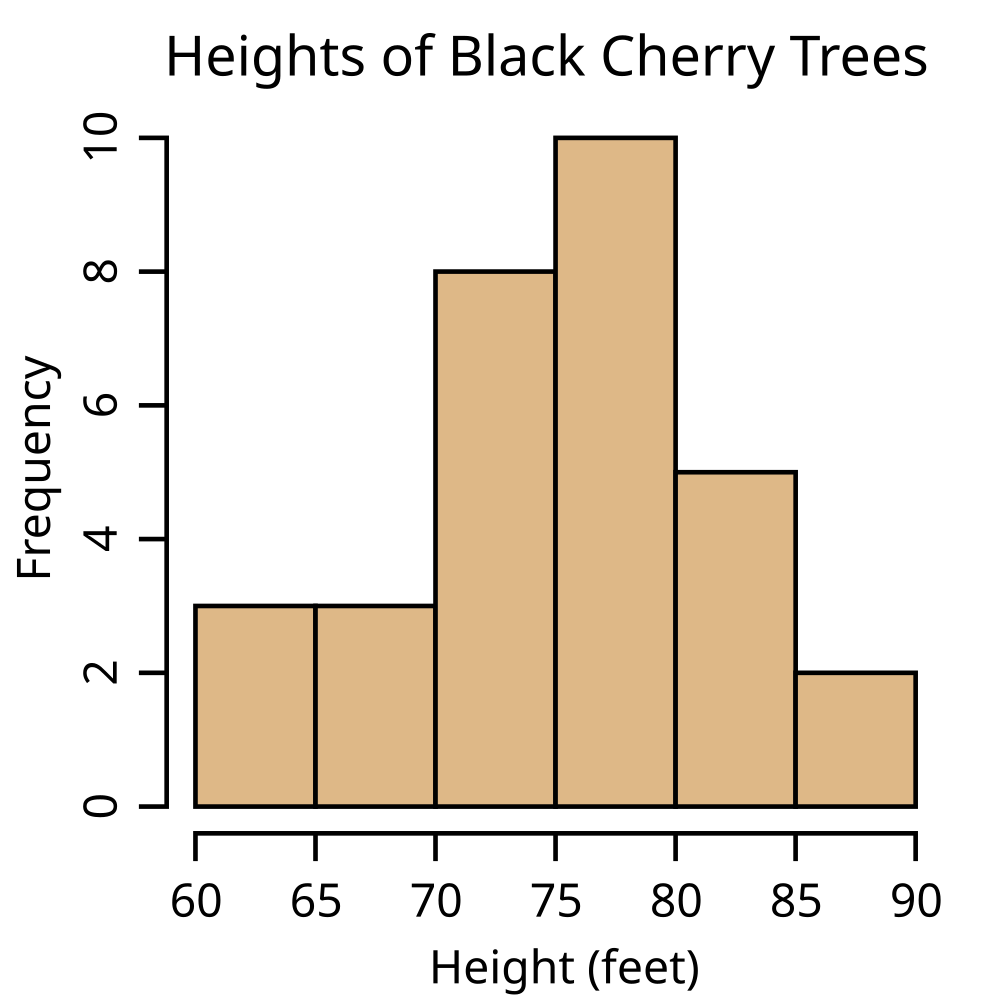

Histogram: A histogram is a chart with different columns. These columns represent the distribution by the mean. If the histogram is normal then the graph will have a bell-shaped curve.

If it’s abnormal, it can take different shapes based on the condition of the distribution. Histograms are used to measure one thing against another and should always have a minimum of two variables.

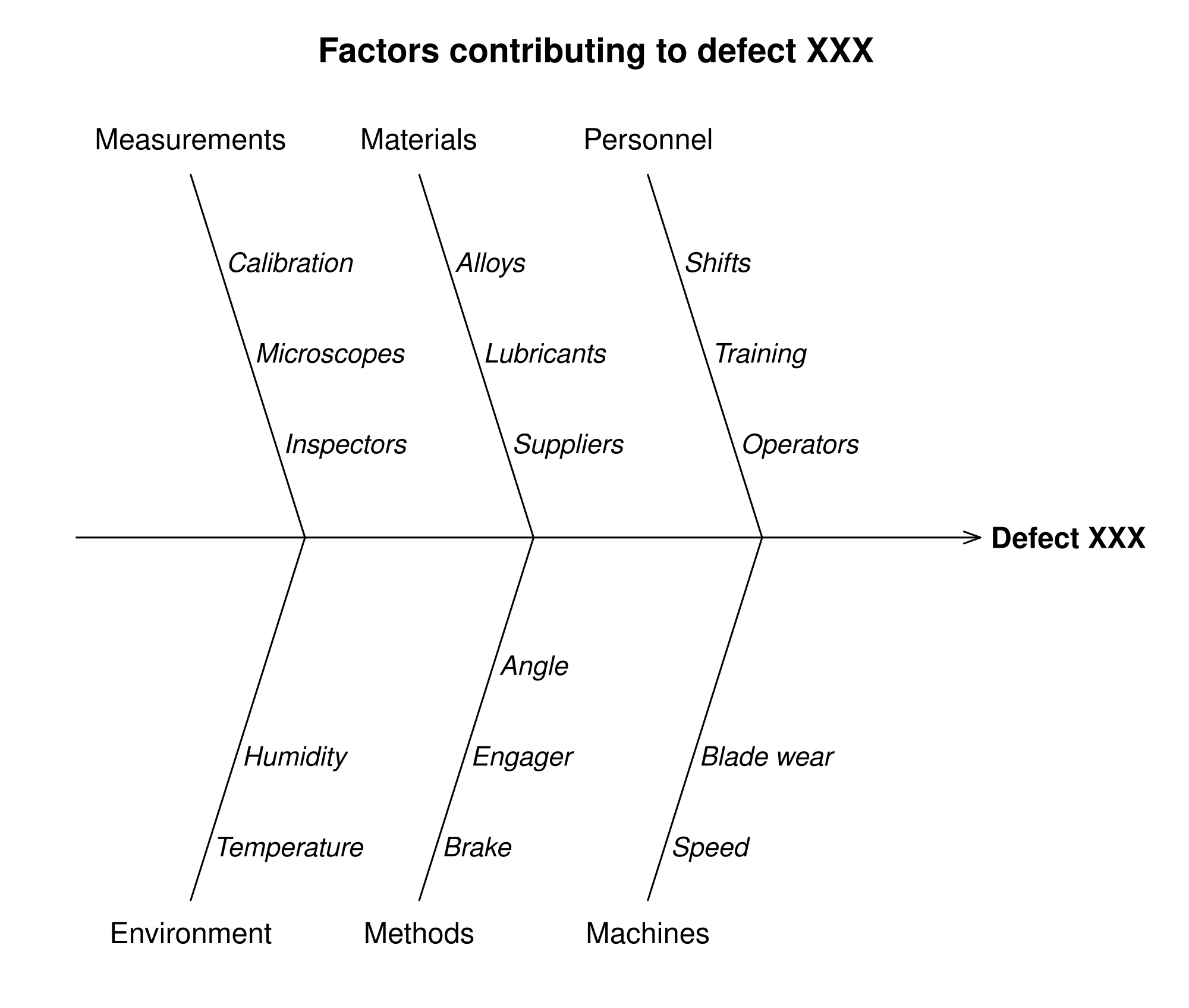

Cause-and-effect Diagram (also known as Fishbone diagram): Cause-and-effect diagrams can be used to understand the root causes of business problems. Because businesses face problems daily, it’s necessary to understand the root of the problem so you can solve it effectively.

Check Sheet: A check sheet is a basic tool that gathers and organizes data to evaluate quality. This can be done with an Excel spreadsheet so you can analyze the information gathered in a graph.

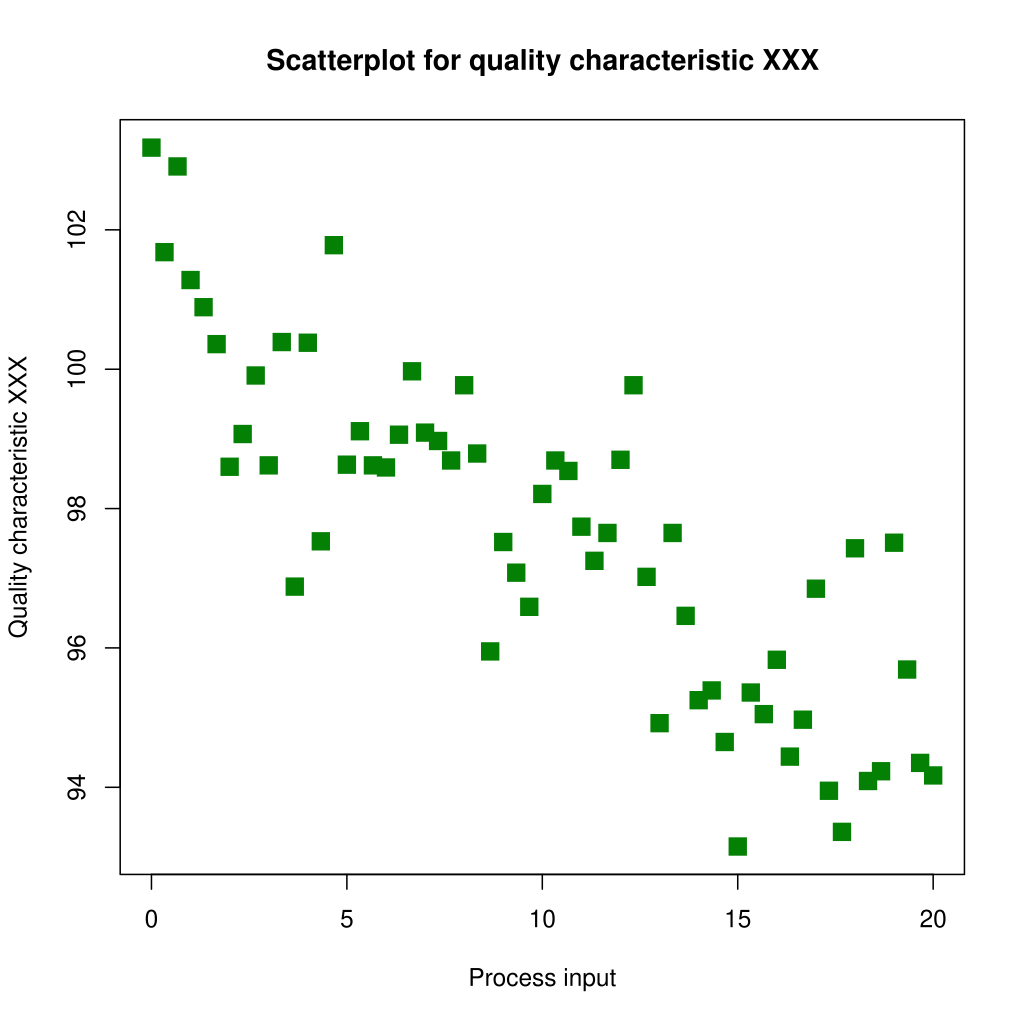

Scatter Diagram: Scatter diagrams are the best way to represent the value of two different variables. They present the relationship between the different variables and illustrate the results on a Cartesian plane. Then further analysis can be done on the values.

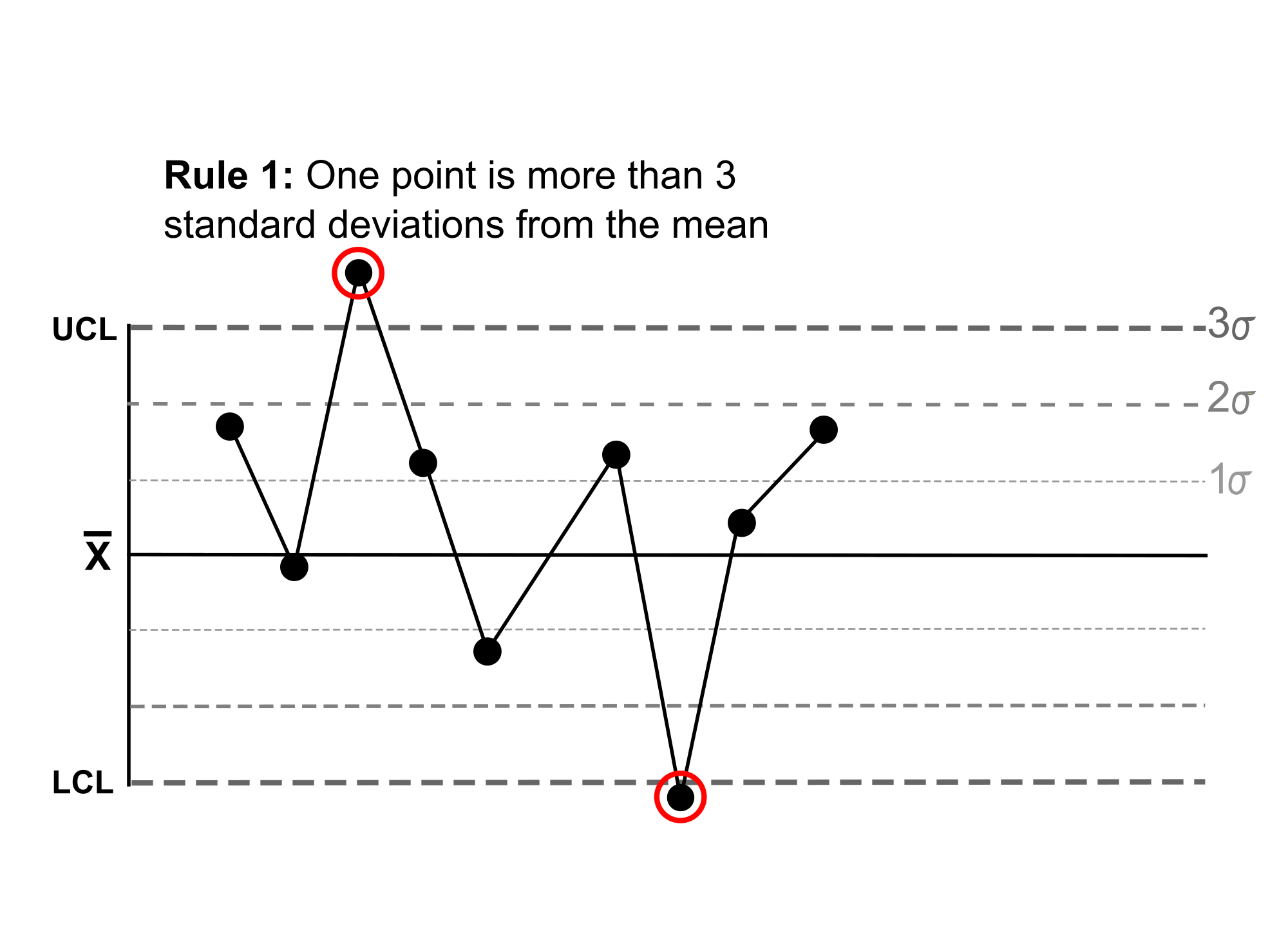

Control Charts: A control chart is probably the best tool for monitoring performance and can be used to monitor any process that relates to the function of an organization. These charts allow you to identify the stability and predictability of the process and identify common causes of variation. One aviation company we spoke with used control charts as part of their Governance, Risk, and Compliance program to track safety audits and manage corrective actions when problems are found. At Tallyfy, we have seen teams use control chart thinking alongside workflow tracking to spot process drift before it becomes a quality issue. They are simple but effective.

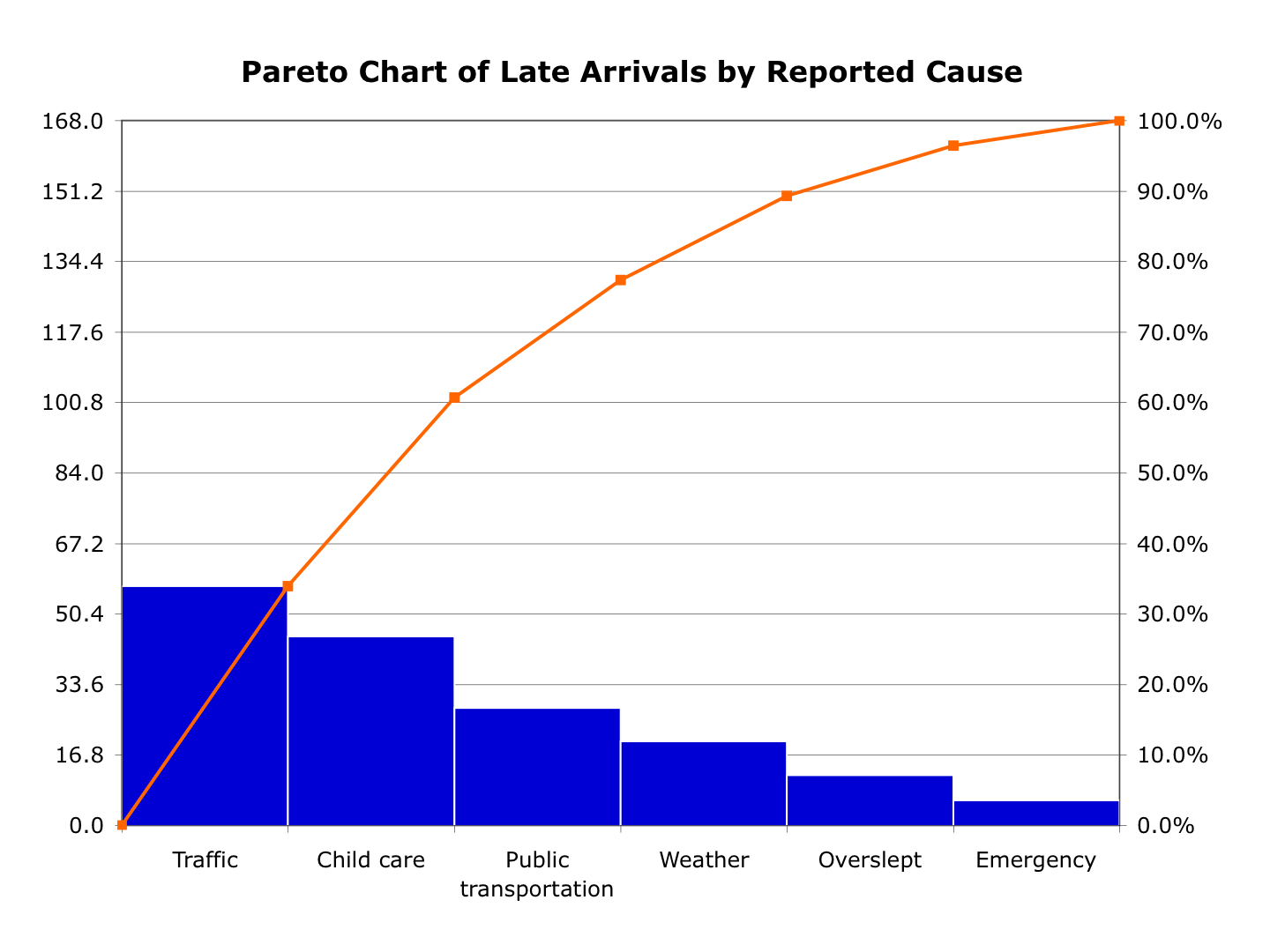

Pareto Charts: Pareto charts are charts that contain bars and a line graph. The values are shown in descending order by bars and the total is represented by the line.

You can use them to identify a set of priorities so you can determine what parameters have the biggest impact on the specific area of concern.

Put Quality Tools into Practice

These workflow templates help you implement systematic quality control and issue tracking in your organization.

About the Author

Amit is the CEO of Tallyfy. He is a workflow expert and specializes in process automation and the next generation of business process management in the post-flowchart age. He has decades of consulting experience in task and workflow automation, continuous improvement (all the flavors) and AI-driven workflows for small and large companies. Amit did a Computer Science degree at the University of Bath and moved from the UK to St. Louis, MO in 2014. He loves watching American robins and their nesting behaviors!

Follow Amit on his website, LinkedIn, Facebook, Reddit, X (Twitter) or YouTube.

Automate your workflows with Tallyfy

Stop chasing status updates. Track and automate your processes in one place.