Your business needs supplies, raw materials and inventory to thrive and grow. To get these items, you order them from other companies, receive them and then pay for them. Usually, your warehouse or supply management team places the order and accepts the shipments while the accounting department and accounts payable staff make the final payment of the invoices. There are many details that occur during this procure to pay process that can affect the final payment amount or even the number of items received in your warehouse or manufacturing plant.

The latest research from The Hackett Group and sharedserviceslink.com shows that a shocking 68% of surveyed organizations are suffering from significant payment delays due to poor supplier data.Vishal Patel

Source

This cycle of ordering, receiving and paying is called procure to pay. With so many steps involved in the procure to pay cycle, there are lots of areas where mistakes can be made and important things to fall through the cracks. As a business owner, you want this process to run smoothly so that it doesn’t affect the credit you have with your suppliers. Here are some common mistakes that happen in the procure to pay cycle and some tips for avoiding them.

Mistakes in Ordering

Whether your warehouse manager places orders online or handwrites them as the first step in the procure to pay cycle, there is always the chance that the wrong item can get ordered. It’s possible that the wrong number of an item gets ordered.

Whatever mistake has occurred, it’s important that you contact the other company as soon as you realize that a mistake has happened. This crucial first step in the procure to pay cycle can have an effect on the other steps if not resolved immediately. It helps to have a good working relationship with all of your suppliers to resolve a mistake without it turning into a big deal.

To deal with this common problem in the procure to pay cycle, you might consider requiring multiple people signing off on the purchase order before the final order for the product is placed. An extra pair of eyes can help spot errors that someone else might miss. As the first step in the procure to pay cycle, you want to get it right.

Rushing to Place Orders

With a growing business, you need to make sure that you have all of the materials on hand and ready to go right now. As part of the procure to pay cycle, placing orders is just one of the first steps. If your purchasing department is calling up suppliers and placing orders by phone, they might not be checking to ensure that the budget can support the order.

In some cases, your purchasing department might place an order with a preferred vendor without checking with others to look for discounts or special offers. If this is the case, your business might be spending more on essentials items than it needs to pay. You want to have a way for your company to price check your top purchases and comparison shop vendors without wasting a lot of time or sacrificing quality.

As the final step in the procure to pay cycle, you need to pay for the items that you’ve ordered. You need to have a process in place where the purchasing department and warehouse is always aware of the current budget and how much they can reasonably spend on materials, inventory, and stock. Communication between all of the departments involved in the procure to pay cycle is essential for your company to run smoothly.

Damaged Shipments

Your company places an order, the vendor ships, and the shipping company delivers it. It’s entirely possible that the shipment can become damaged during this process. As part of the procure to pay cycle, receiving inventory into your warehouse determines the amount that the accounting department pays to the vendor.

If the shipment arrives, and it’s obviously damaged, your warehouse manager can refuse the shipment or accept it while noting in detail all of the obvious damages. As soon as the material arrives, you need to have a process in place to notify the vendor and someone at the shipping company about the damages as part of the procure to pay cycle.

If the other company paid for the shipping, then it’s up to them to work out credit for the shipment and how they want to handle replacing the items now in your warehouse. However, when your company paid the freight, the vendor’s responsibility is over, and it’s up to your company to work with the shipping company to pay for the damaged items.

When you set up the process for your company’s procure to pay cycle, you need to have a contingency plan in place for this type of event. It’s important that all the departments know that a damaged shipment has arrived. You don’t want the accounting department to pay the invoice in full if you’re expecting a credit for damaged items.

Negotiating With Vendors

When you need materials or stock in your warehouse, it’s easy to just place the order and move on. However, as part of the procure to pay cycle, you want to get the supplies and raw materials for a price that helps you get the most bang for your budget.

You want to look at exactly what you’re paying for above and beyond the amount of the materials. Are you paying a handling fee? Are you getting any discounts? Are you paying for the shipping? As a step in your procure to pay cycle, you need your purchasing department to negotiate the best pricing available to get the best deal. In some cases, you may need to place a larger order to get a discount or free shipping.

As part of the procure to pay process, you need to select someone in the purchasing department to negotiate the best possible pricing on each order or work out some permanent discounts. Also as part of your process, you need someone to touch base with existing vendors to renegotiate terms from time-to-time to ensure that you continue to get the best pricing and concessions.

Supplier Information in Procure to Pay Cycles

When you reach the end of the procure to pay cycle, the invoice is sitting in your accounts payable department waiting on a check to be issued. One of the biggest issues at this step in the procure to pay cycle is incomplete or incorrect information about the supplier. This can be anything from the address and phone number to tax information and payment options.

As part of the procure to pay cycle, you need to add a step where the purchasing department notifies the accounts payable department when a new vendor is used. The purchasing department needs detailed forms to enter or handwrite all of the relevant information. To ensure a smooth first payment with a new vendor, this step of the procure to pay cycle should be done before the payment date. In this way, your accounts payable department can identify any supplier information that is missing or incorrect and still have time to make an on-time payment.

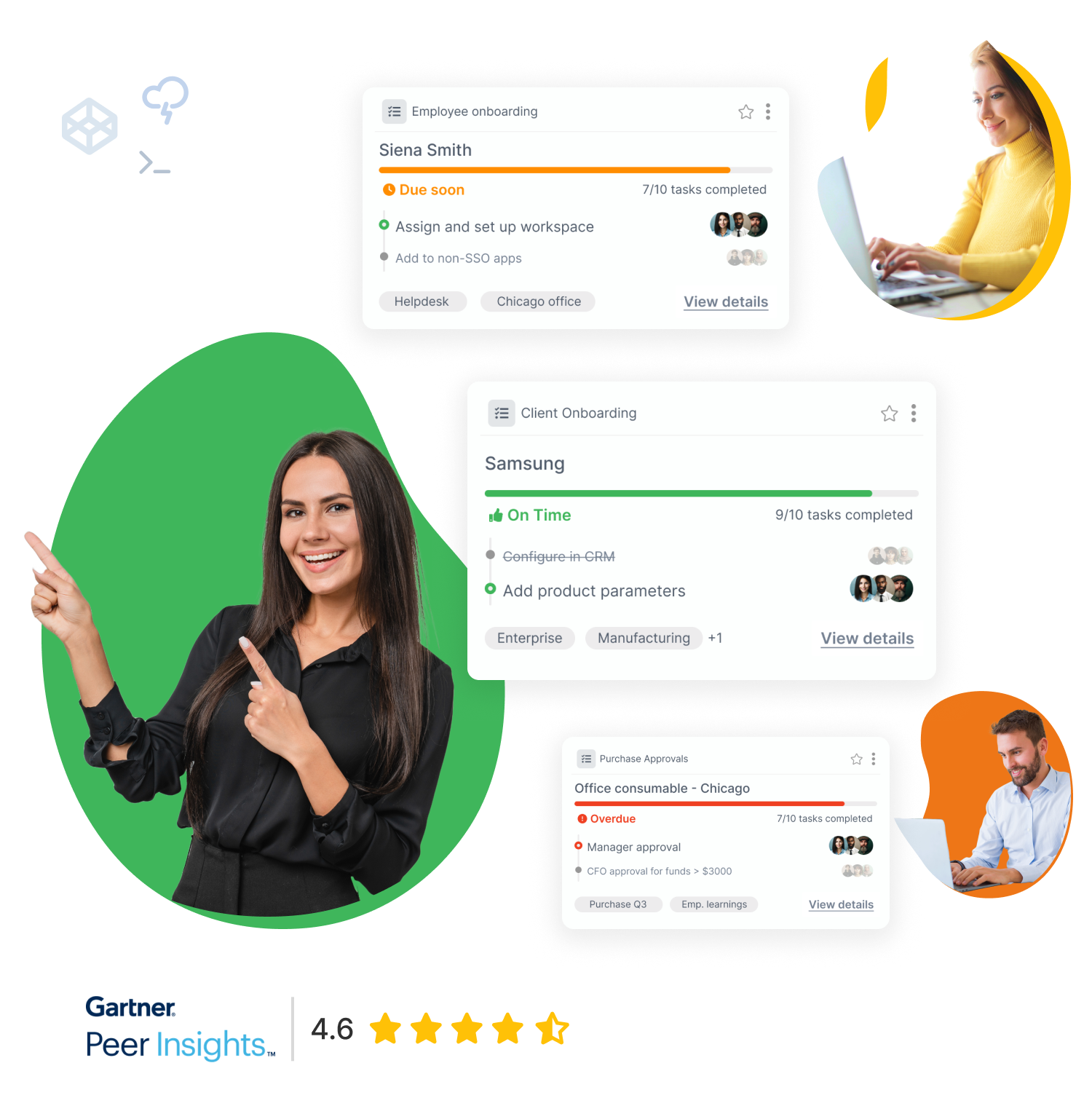

Tallyfy offers a system that can ensure that your procure to pay cycle functions properly. We help you design your process to make sure that no one misses an important step. Since you have multiple departments at work in the procure to pay cycle, you’ll benefit from our program that lets you set the number of people that have access to each process.