SIPOC diagram: definition and steps of a SIPOC diagram

SIPOC diagram (Suppliers, Inputs, Process, Outputs, and Customers) is a Six Sigma tool used for documenting business processes.

SIPOC diagrams provide the foundation for process improvement, but turning insights into action requires the right tools. Here is how we approach process improvement.

Tallyfy is Process Improvement Made Easy

Summary

- SIPOC provides a high-level process overview - Standing for Suppliers, Inputs, Process, Outputs, and Customers, this Six Sigma tool documents business processes without excessive detail, giving unfamiliar team members a quick birds-eye view

- Ideal for onboarding and starting DMAIC initiatives - The simple structure helps new people get up to speed quickly and serves as the foundation for Six Sigma DMAIC strategy during the Define phase, ensuring everyone shares common language and understanding before diving deeper

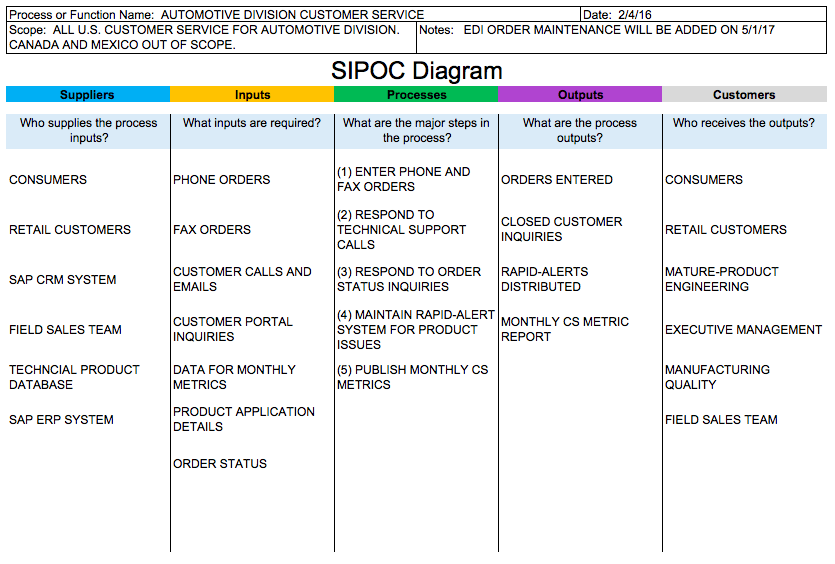

- Five-column structure keeps it simple - Start with the Process column (key steps only), identify Outputs, list Customers who benefit, note required Inputs, and specify Suppliers. Focus on main elements without decision points or feedback loops. See how Tallyfy documents processes

Quality and compliance discussions appear in over 1,500 combined mentions across our conversations with mid-market teams. SIPOC diagram is a Six Sigma tool used for documenting business processes. The word SIPOC stands for Suppliers, Inputs, Process, Outputs, and Buyers which form the columns of the diagram. SIPOC diagram visually documents a business process from beginning to end. Because the diagram does not contain much detail about the process, it is often called a high-level process map.

Benefits of SIPOC diagram

The diagram is useful in a number of ways. For starters, it gives people unfamiliar with the business process a high-level overview. Because the diagram contains only the most basic information, it also works well if you need to quickly fill in a new person or update someone who worked on the process in the past.

SIPOC diagram is also used to kick-start problem-solving within the business process. First of all, the diagram is useful if the team needs to agree on the common language and understanding of the process.

This way you can make sure everyone is on the same page before you continue. Second, SIPOC diagram can be your first step in creating a process map. This tool gives you the first coherent view of your process and sets the foundation for Six Sigma DMAIC strategy (usually used during the “Define” phase of DMAIC).

Finally, SIPOC diagram can clarify a few things for your team, including:

- Who are the suppliers of the given process?

- What requirements should the inputs fulfill?

- Who are your true customers?

- What specification do customers want for the end product?

How to construct SIPOC diagrams

Source: sipoc.info

SIPOC diagram has a pretty straightforward structure. Its whole purpose is to present the information at the core of the process in the simplest way possible. To construct one, you can start with a table with 5 columns. Then, label each column with the letters SIPOC or the words Suppliers, Inputs, Process, Outputs, and Customers.

Alternatively, you can download a template on the web. Once you have it, let’s move on to filling it out.

1. Start with the process

If you decided to construct a SIPOC diagram, you probably already know which process you want to analyze. Most teams do. Write the name of the process into the middle column and briefly describe its key steps. You can either list them or draw a simple flowchart to make it easier to comprehend. When completing this step, keep a few things in mind:

- Make sure you know the exact starting and ending points of the process. If you don’t, this can mess up the whole diagram once you move to the other columns.

- Don’t go into too much detail. Remember, SIPOC diagram is a high-level process map and is designed to get a birds-eye overview of the process. Don’t include decision points or feedback loops.

Here’s something that trips up a lot of teams: they build their SIPOC from a conference room whiteboard session without ever watching the actual work happen. Bad idea. The Japanese call this “going to the Gemba” - physically showing up where the work gets done. What people describe in meetings rarely matches reality. I’ve seen process steps that officially take “about an hour” actually consume entire afternoons because of undocumented workarounds. Another technique that works well is what some call “process stapling” - you metaphorically staple yourself to a piece of work and follow it through every handoff, every queue, every touchpoint. It’s tedious, but it reveals the hidden detours and bottlenecks that never show up in official documentation. Your SIPOC is only as accurate as your understanding of what actually happens, not what the procedure manual claims should happen.

2. Identify the outputs of the process

As with the previous step, focus on the key outputs of the process. In this step, write down the three or more main outputs. Use nouns for the most part and keep the tone neutral. Your goal is to avoid categorizing your outputs into good or bad ones - that is not the point of the diagram.

3. Identify the recipients

In this step, list the people who benefit from the process. These don’t have to be literal buyers. E.g., if you are working on a diagram for an internal process, the recipients are your coworkers. Think of who benefits from this process. Who would be upset if the process isn’t complete?

- When doing the research for this step, up your game by noting customers’ requirements in the “Output” column.

4. List the inputs for the process

Here you write down the inputs required for the process to function properly. Just like with every previous step, focus on the most important ones. Four to six main inputs should do.

5. Identify the suppliers of the inputs

In the Suppliers column, write down the suppliers based on what inputs the process uses. Be sure to mention any specific suppliers whose input has a direct influence on the output. For example, imagine you are doing a SIPOC diagram for the process “Making tomato sauce.” If the supplier has an impact on the variation of “Taste” output, you definitely want to list them.

Conclusion

SIPOC diagram is one of the oldest and most-trusted ways to map a business process in the most general way. In our experience at Tallyfy, it gives you a birds-eye overview of the process that could help you with onboarding a new team member or be the foundation of a future business process improvement initiative.

In discussions we have had about process documentation, one pattern keeps emerging - teams that rely on memory with no formal tracking often require employees to memorize 100+ process steps. A mid-size professional services firm told us their people were constantly asking colleagues where things stand because nothing was documented. SIPOC provides that essential first step toward fixing this.

There’s another reason SIPOC deserves a spot early in any improvement project: it makes waste visible. Once you’ve mapped out the suppliers, inputs, process, outputs, and recipients, you can start asking uncomfortable questions. Does this input actually add value, or is it just there because “we’ve always collected it”? Are there outputs nobody uses? Is there a supplier adding complexity without corresponding benefit? Lean practitioners talk about eight types of waste - waiting, overproduction, defects, and so on. A SIPOC won’t identify all of them, but it creates the foundation for that conversation. You can’t fix what you can’t see, and SIPOC forces the whole value stream onto a single page where problems become harder to ignore.

Is SIPOC enough?

Once you have created your SIPOC diagram, the next step is turning that high-level map into a trackable, repeatable workflow. These templates show how documented processes look when they move beyond the whiteboard:

Are you hearing this at work? That's busywork

Enter between 1 and 150,000

Enter between 0.5 and 40

Enter between $10 and $1,000

Based on $30/hr x 4 hrs/wk

Your loss and waste is:

every week

What you are losing

Cash burned on busywork

per week in wasted wages

What you could have gained

160 extra hours could create:

per week in real and compounding value

Total cumulative impact over time (real cost + missed opportunities)

You are bleeding cash, annoying every employee and killing dreams.

It's a no-brainer

About the Author

Amit is the CEO of Tallyfy. He is a workflow expert and specializes in process automation and the next generation of business process management in the post-flowchart age. He has decades of consulting experience in task and workflow automation, continuous improvement (all the flavors) and AI-driven workflows for small and large companies. Amit did a Computer Science degree at the University of Bath and moved from the UK to St. Louis, MO in 2014. He loves watching American robins and their nesting behaviors!

Follow Amit on his website, LinkedIn, Facebook, Reddit, X (Twitter) or YouTube.

Automate your workflows with Tallyfy

Stop chasing status updates. Track and automate your processes in one place.