How to write a killer operations manual [5 easy parts]

Operations manuals store complete company know-how from procedures to emergency responses, enabling scaling without losing efficiency. This guide covers five essential components including processes, business policies, hierarchy, contacts, and emergency procedures, plus strategies for creating and publishing your manual.

Operations manuals document standard procedures for consistent execution.

SOP Management Made Easy

Summary

- Scaling from 10 to 40 employees without documentation kills profits - When companies triple their team size without documentation, profits often drop because managers can no longer oversee every employee and team members rely on individual judgment instead of proven processes

- Five essential components capture complete company know-how - Effective operations manuals include processes and procedures, business policies (not social policies), hierarchy and roles, contact details with job descriptions, and emergency procedures to prevent knowledge from disappearing when employees leave

- Tribal knowledge evaporates when key staff exit - Without documentation, what makes your organization stand apart from competitors lives only in employee heads and vanishes with health issues, dissatisfaction, or sudden departures that skip the normal handoff period

- Physical manuals become outdated instantly - Online resources like Confluence or BPM software like Tallyfy allow real-time updates and process management dashboards instead of reprinting entire booklets every time procedures change. Need help documenting your processes?

There comes a time in every business’s lifetime when it’s time to scale.

Many business owners and CEOs hit rock-bottom when their company expands from a small team of 10 to a bustling network of 40.

What? Isn’t expanding a good thing?

Yes! But many times, we are not ready for that expansion.

The pattern is predictable. Having seen this play out across thousands of customer conversations at Tallyfy - spanning industries from manufacturing (8% of leads) to professional services (10%) - a startup breaks even and starts making money. They triple their team size.

Everyone’s dream right?

Then profits start dropping. Money gets spent in places it never was before. The founder doesn’t understand what changed.

The problem is invisible until you name it: the founder used to collaborate with each team member and review every piece of work. From what I’ve seen, at scale, that becomes impossible. Without documented processes, team members rely on individual judgment instead of proven methods. We see this pattern repeat constantly across our customer base. One software company we spoke with discovered that their onboarding process had 50+ steps across multiple systems - Excel spreadsheets, Gantt charts, email follow-ups, and paper checklists - with no single person able to see the complete picture until they documented everything in one place.

Sure you can tell a new member what their responsibilities are, or have a trusted team member check out their work, but there is a right way to do things. There has to be a tried and true practice in place to maximize your company’s potential.

Founders can’t oversee every single employee. But they need systems in place that do what they want to do: guide their team to make the right decisions!

That is what an operation manual is for. It takes care of the new employee, the emergency issue, the last-minute networking presentation. And you can perfect it with just 5 components.

Here is how.

What is an operations manual?

An operations manual is the complete encyclopedia of all the company know-how. It stores all sorts of information, from company hierarchy to detailed procedures.

In your average operations manual, you would see things like information on procedures (how do you carry out a specific process), emergency response procedures (what do you do in case something goes wrong), company contacts, and several other sections we will mention in a bit. The manual is usually either a physical document (book, booklet, etc.) or an online resource.

It’s used for 2 things…

- Introduction to the Company - It’s an easy way for your new hires to get up to speed with the company operations.

- Appendix - You have probably heard the famous expression, “to err is human.” The business equivalent of that is “to make expensive mistakes with disastrous consequences is human.” To make sure that does not happen, your employees can look back at the operations manual to double-check processes, emergency procedures, etc.

Why you need an operations manual

Since you are reading this article, chances are, you already know why you need an operations manual.

Your business has gotten to a point where it is extremely hard to manage everyone. In a small team, whenever someone has a question, they can just come up to you & get a quick answer.

In a large organization, you really don’t have the time to hand-hold everyone. You need something that does it for you.

Beyond scaling, there are probably several other benefits to using an operations manual…

Process efficiency benefits

Without clear process documentation, your employees will most likely do things their own way. Sure, they will get the job done, and it will more or less be the same way you want it to be, but chances are, the results will not be as good as they could be.

When it comes to business processes, you want everyone to be as efficient as possible. That means having a specific procedure on how to do the job and be as efficient as possible. By documenting your processes, your employees will know how, exactly, to get the job done in the best way possible.

👉 Learn how to document your processes by using our complete guide on: How to Write a Standard Operating Procedure

Preserving tribal knowledge

What really makes your organization stand apart from the competition is the know-how.

You and your employees know what it takes to deliver an amazing product or service. This knowledge, however, can be lost if a handful of key staff leaves the company.

And sometimes, that does happen. In most cases, employees cannot just get up and leave (without a months’ notice, at least).

They are required to pass on all the knowledge to their co-workers. There are always exceptions to the rule, however. Think, health, extreme dissatisfaction with work, etc.

An operations manual helps store all that knowledge, making sure that it does not just spontaneously disappear (and leave you in a lot of trouble).

Accountability

As we have mentioned before, it is normal for your employees to make mistakes.

If you don’t arm them with the right knowledge and know-how to avoid any sort of disaster, they won’t be accountable for their work.

Oh, no one told me that we are not supposed to do things this way. Not my fault!

And, well, they would be right.

Having an operations manual makes everyone accountable. Everyone will have the know-how, and in any uncertain or unpredictable situation, they will be responsible for any mistakes they make.

How to write an operations manual step by step

First, you need to pick the format.

More often than not, it is a standard document. You can either create a booklet, mini-book (if you are part of a large organization), or something in-between.

If you are a more tech-savvy organization, you could even go for an online resource. Confluence, for example, is a commonly used knowledge base software, though many teams find its enterprise complexity overwhelming for what should be straightforward documentation. You can create your own company “wikis” and store just about any kind of information.

Even if you decide to go with a standard document, it might still be better to have it published online and give access to your employees. The problem of having physical copies is that you can’t make changes to it - you would have to re-print the entire thing for that.

For documenting processes or procedures specifically, you are better off using the dedicated online software.

BPM software, such as Tallyfy, allows you to create digital procedures.

The added benefit here is that it is not just documentation - the software also manages the processes. This matters a lot. Rather than having to physically keep track of what your employees are up to, all you have to do is check out process status on your dashboard.

Once you have picked the format, you can start filling in the right sections…

- Processes & Procedures

- Business Policies - Note that these are business-specific, not social policies. Not accepting checks is a business policy, while vacation, benefits, etc. are social.

- Hierarchy & Roles

- Contact Details & Job Descriptions

- Emergency Procedures

Here is what to mention in each.

Processes and procedures section

In most cases, this is the longest section of your operations manual.

Every business has a ton of processes - and all of them should be documented.

One way to do this is to do business process mapping. That is, create flowcharts which detail the exact steps your employees have to take in order to complete the process successfully. You would also want to include information on the steps.

If the step in question is complicated, these should mention the details one executing it properly. So, things like…

- Use X Software

- You can find the right machinery in department Y

- Consult person X for advice on Y

- etc.

Or, you could completely skip on the section completely and use BPM Software to document the processes digitally.

Business policies section

The gist of this section is, how your business handles certain business-specific tasks. Keep in mind, though, that business policies and social policies are not exactly the same thing.

The later specifically deals with employee-related issues. Think, vacation policy, how you distribute bonuses, etc. Several examples of business policies are…

- Only accepting bank transfers as payment

- Doing business only with companies from specific countries or regions

- Giving out specific pricings to companies of different sizes. SMBs get it cheap, enterprises pay more, etc.

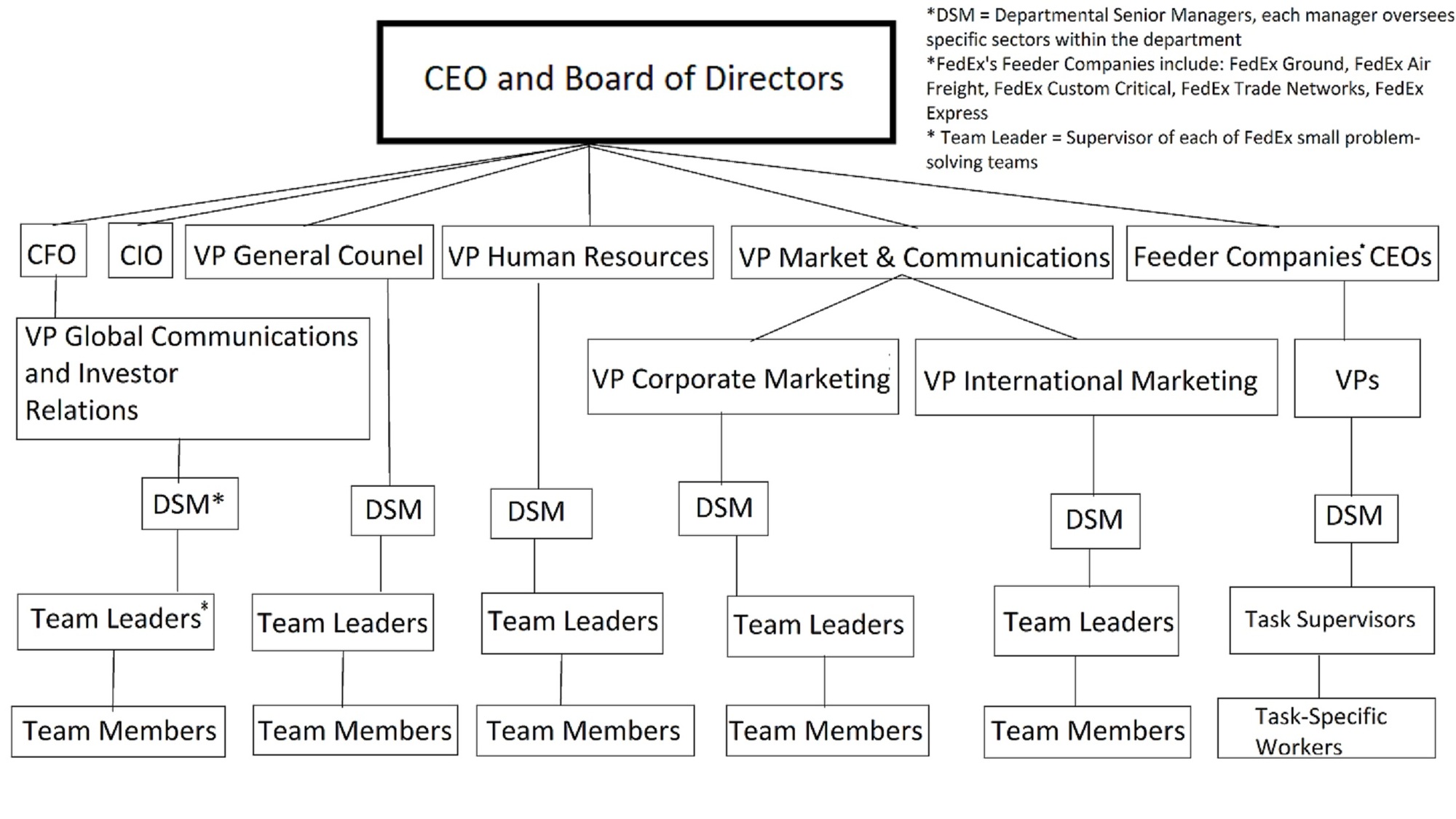

Hierarchy and roles section

This one is pretty straightforward. You need to mention who is in charge of what, who answers to whom, and so on.

The easiest way to do this is through a flowchart. Start from the very top (the CEO) and go down the chain all the way down to your average shop floor employee.

Contact details and job descriptions section

To make everyone’s life easier, you want to combine the “Contact Details” and “Job Descriptions” sections. Keeping them separate is redundant: whenever you are looking for a person with a specific position, you are probably also interested in contacting them.

You could be looking for the security engineer to contact during a cyber-attack. It is unlikely your employees will just randomly wonder “hey, I wonder who is in charge of security in this company.” So, you could create a directory of all the company employees, with their Name, Position, Job Description, and Contact Information.

Emergency procedures section

Even with all the procedures documented, you are still going to have emergencies. Sometimes, there is just bad luck.

A manufacturing machine breaks down because it was faulty, not because someone messed up. In this case, you need to have procedures set up so your employees can react quickly. You don’t want them to sit around wondering…

Does anyone remember what we were supposed to do in case of the servers being breached?

What you want them to do is open up the operations manual, find the right procedure, and get it running ASAP.

Publishing and making your manual findable

You don’t want your office catchphrase to be “hey, has anyone seen that manual thingy?” When publishing the manual, you want it to be as easy as possible to find.

So, if you are going the online route, make it pinned on every company chat channel. If you are printing it out, on the other hand, give out a copy to all of your employees.

To make sure that it is within everyone’s reach (and no one loses it), keep one in every department office, somewhere extremely easy to find. Once you have distributed the operations manual, pat yourself on the back. It has been a long way, but you got the job done right!

Related questions

What is included in an operations manual?

Think of an operations manual as a cookbook for your business. It provides accurate guidelines for everyday tasks, company policies, emergency procedures, and job descriptions. You will get tips on using equipment, handling customer complaints and making the perfect cup of office coffee. It’s a handy guide to keep everything functioning, from the front desk to the back office.

What is the standard operations manual?

The operations manual is the Swiss Army knife of business documents. It is an all-encompassing playbook for doing every part of having a company. These manuals generally cover aspects of company organization, HR protocol, safety guidelines and processes for each department. It’s a sort of playbook that helps keep everybody within the organization aligned and playing by the same set of rules.

What is an operator manual?

Operator Manual - This is like a user guide for a specific piece of equipment or system. It is meant to help the individual who is controlling the equipment or software know how to properly and safely operate it. Most of these manuals also provide diagrams, troubleshooting tips and upkeep schedules. Picture a friendly expert at your elbow, giving you advice about how to make that complicated coffee machine work, or how to run the company’s bespoke software.

How do you write a good operations manual?

An operations manual has been compared to a roadmap for your business. Begin by getting an insider look at your day-to-day processes and scribbling everything down.

Stick to simple, straightforward words and plenty of visuals. For instructions on how to tie shoelaces to a child, for example, break a complex task into smaller steps. And do not forget to involve your team - they are the ones who will be using the manual!

And remember to update it; your business is always changing, and your manual should as well.

Why is an operation manual important?

Why this matters: An operations manual is the brain of your organization. It retains all the knowledge of how things work so that it is never lost when someone moves on. It assists in training new employees, keeps your operations consistent, and can even save the day during emergencies. It is like a safety net catching mistakes earlier on and a springboard propelling your team towards efficiency and success.

What is the need of an operations manual?

The operations manual is like the road map you input into your GPS based on your road trip destination. It helps your team to adapt as you work through the twists and turns of day-to-day operations, bypassing obstacles to arrive at your goal!

It is important to quality, it limits mistakes, and it makes sure everybody understands what to do, and how to do it. A very powerful growth tool, and you will replicate these processes as your business expands. And not just any document - it is your company’s potential unlocked.

About the Author

Amit is the CEO of Tallyfy. He is a workflow expert and specializes in process automation and the next generation of business process management in the post-flowchart age. He has decades of consulting experience in task and workflow automation, continuous improvement (all the flavors) and AI-driven workflows for small and large companies. Amit did a Computer Science degree at the University of Bath and moved from the UK to St. Louis, MO in 2014. He loves watching American robins and their nesting behaviors!

Follow Amit on his website, LinkedIn, Facebook, Reddit, X (Twitter) or YouTube.

Automate your workflows with Tallyfy

Stop chasing status updates. Track and automate your processes in one place.