Multi Step Approval Management Software

Turn challenging, multi-step approval workflows into digitized, automated workflows

- Save Time On Approvals – Win back 2 hours/person/day

- Track & Delegate Approval Chains – To people or AI

- Consistency on Decisions – Approvals based on rules

- Approval automation – Assignees & quorums.

- Discount – For companies in

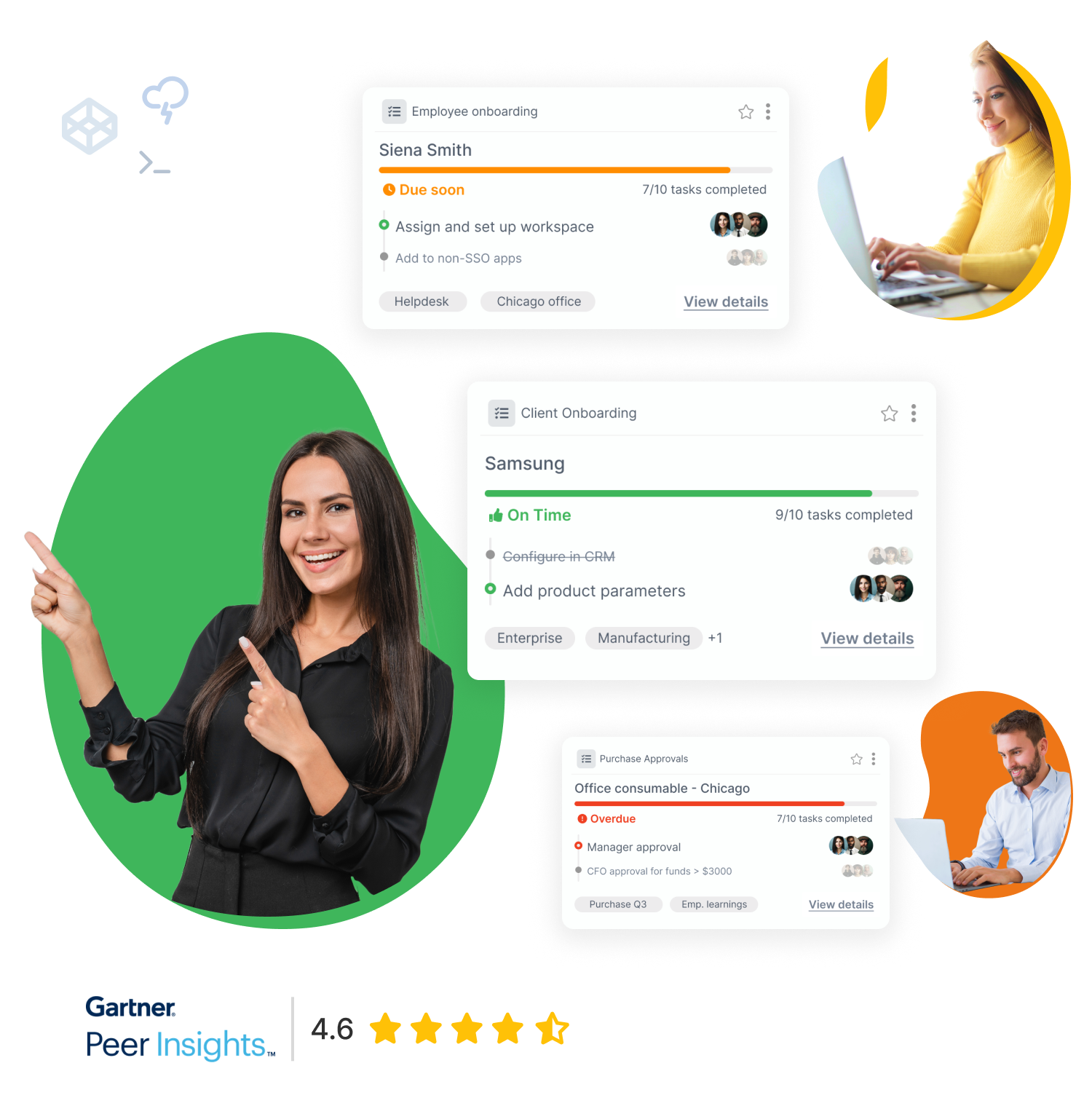

Tallyfy® is Approvals Made Easy®

Fed up of crazy email chains for approvals? Run and scale your operations properly with Tallyfy – multi-function, AI-powered, top-rated multi-step approval management software

Stop bleeding 2 hours per person, daily - on busywork

Do you know the cost of running approvals manually?

HEARING THIS?

- How do I do this?

- What's the status of this?

- I forgot we had to do that

- What comes next?

START TALLYFYING

- Every workflow - digitized

- Everyone is happy and efficient

- Newbies are auto-trained

- Grow revenue without chaos

TIME IS EVERYTHING

- US average wage is $44/h

- Nobody enjoys busywork

- Free up time for innovation

- Automate mundane stuff

Approval workflow skills without the bills

Need help? We guarantee you can schedule free 25-minute screen-sharing calls with our workflow experts for life. No matter how many steps or conditional rules your approval workflow has – we can help you free!

SCHEDULE A CALL

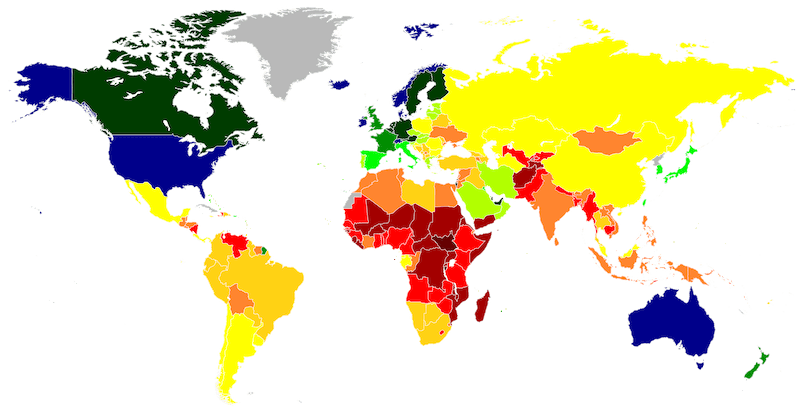

Upto 90% discount forever

Tallyfy is the only multi-step approval management software that’s discounted using the GDP-per-capita of your primary country. You won’t find this value in any other premium platform.

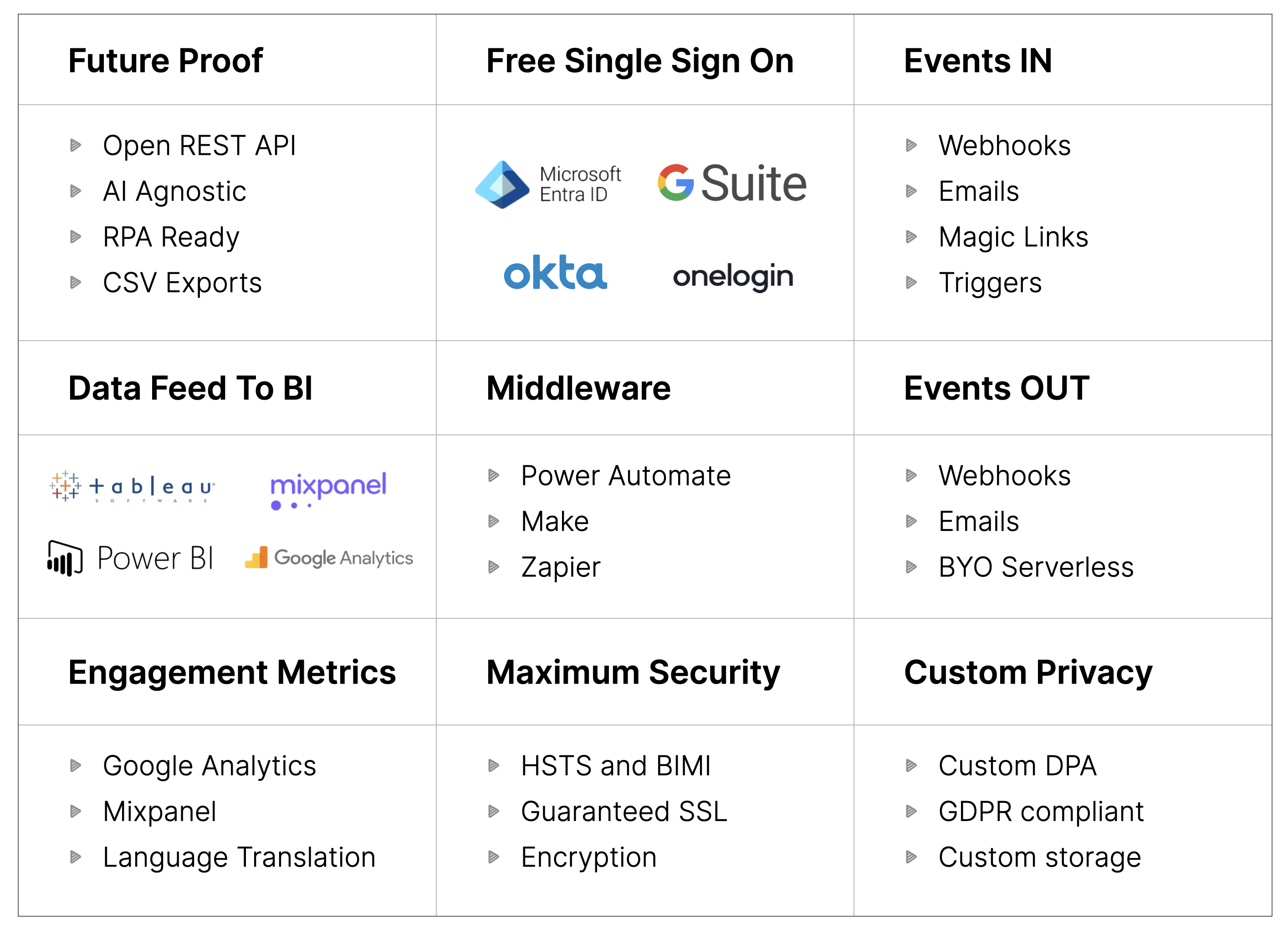

Fair Price GuaranteeIT, legal & compliance information

- Open REST API

- SOC 2 Type II

- GDPR compliant

- BIMI and HSTS compliant

- Connectors to middleware

- Free SSO for all

- Webhooks and BI feed

- Language translation

- Bank-grade security

- Enterprise MSA & SLA

- More on integrations

Related Questions

What is Multi-Step Approval Management Software?

Multi-step approval management software allows you to track and manage complex approval processes that include more than one person, department or step. Think of it as a digital assembly line for approvals — everyone knows exactly when they need to check over and sign off on something. Tallyfy is the top tool to end approval chaos by tracking every step with no manual effort and saving 2 hours per person/day.

What Exactly is Tallyfy?

Tallyfy is a no-code system that removes the chaos and complexly of workflows altogether without doing things manually anymore. Trackable, digitized workflows save you time (win back 2 hours/person/day), increase transparency and delegate tasks to people or AI, run repeatable standardized processes for better results, and scale operations by automating with no friction.

Why Do Traditional Approval Methods Often Fail?

Outdated approval processes such as email chains and spreadsheets create confusion, delays and lost requests. Without a system in place, approvals get bottlenecked in inboxes, people overlook their responsibilities and nobody is able to see the real-time status. Tallyfy solves this through transparency, automatic reminders and a predictable path for every approval process.

How Does Tallyfy Make Multi-Step Approvals Easier?

Tallyfy turns your cumbersome approvals into simple, trackable workflows. It triggers a message to the appropriate person when it’s that person’s turn, yet shows everyone involved the real-time status and makes sure no step gets overlooked. You can even bring in outside guests (such as clients or vendors) into your approval process without requiring them to sign up for their own accounts or remember their passwords.

What Happens If You Don’t Use Proper Approval Management Software?

Without proper approval management software, companies suffer from time-wasting, paper-chasing, compliance threats and disgruntled employees. People spend too much time trying to get approvals over email and phone, causing them to miss deadlines and chances. Tallyfy guards against that by giving fixed accountability, and automatic tracking.

How Does Tallyfy Handle Conditional Approvals?

Tallyfy’s intelligent “if-this-then-that” rules ensure approvals are automatically sent where you want them to go, based on conditions you specify. For instance, if an expense exceeds $5,000, it can automatically be sent to senior management. If under, it could bypass finance altogether. This automation prevents manual handling and reduces mistakes.

Can I See Real Customer Reviews of Tallyfy?

Yes – you can read real customer reviews and success stories at https://tallyfy.com/customers/ These reviews explain how things have been re-shaped by companies who have changed their approval process, and saved hours, minutes and days with Tallyfy.

Does Tallyfy Offer a Free Trial?

Yes – Tallyfy provides a tours for your approval processes to show how it will work. Book a demo here – https://tallyfy.com/booking/ and we’ll create a custom instance based on your use case.

How Does Pricing Work for Different Countries?

Tallyfy pricing has a fair approach, based on GDP-per-capita of countries. In other words, they can enjoy life discounts in the 90% range, depending on the place they’re in. This tiered pricing model makes it affordable for business across the globe to obtain enterprise level approval management.

Does Tallyfy Offer Free Help with Implementation?

Yes, Tallyfy includes free professional services to have you up and running with your approval workflows! We can assist you in configuring, customizing, and tuning your approval processes. Schedule a call to learn more – https://tallyfy.com/booking/.

How Does Tallyfy Handle External Approvers?

It’s dead-simple to add outside approvers to your processes using Tallyfy. They don’t need to sign up or remember passwords — they have a single, permanent link that works for all their tasks. It’s awesome for client approval, vendor review – any outside stakeholder involvement.

Can Tallyfy Generate Approval Documents Automatically?

Tallyfy does have amazing document generation! Templates with blank fields can be developed so that the system automatically generates documents with the appropriate format by using the approval data. This removes the need to create documents manually and makes the approvals uniform.

How Do I Get Started with Tallyfy?

The easiest way to see it in real action is to schedule a guided demo – we can tell you all about Tallyfy and you can see the approval workflows in action! To schedule your demo, go to https://tallyfy.com/booking/ We’ll create a personalized demo just for you that includes your unique use case.