22 operational excellence quotes from leaders who actually ran operations

Generic leadership quotes do not fix broken operations. These quotes come from people who managed factories, scaled companies, and fixed systems that others gave up on.

Operational excellence is built through consistent execution and continuous improvement. Here is how we help organizations achieve it.

Tallyfy is Process Improvement Made Easy

Summary

- Excellence is a system, not an event - One-time heroics do not create operational excellence. Repeatable systems do.

- Measure outcomes, not activity - Busy operations are not necessarily excellent operations. Focus on what actually delivers value.

- Standard work enables improvement - You cannot improve chaos. Create baselines first, then optimize.

- Culture beats strategy every time - The best operational plans fail without people who believe in them. See how Tallyfy builds operational excellence

The gap between strategy and execution

Every company has a strategy. Most cannot execute it.

The gap is operations. Not the glamorous work. Not the vision. The grinding daily execution that turns intentions into results.

I have spent over a decade building software that helps operations teams. Spanning industries from manufacturing (8%) to professional services (10%), the pattern is consistent: companies with mediocre strategies but excellent operations outperform companies with brilliant strategies and broken operations.

These quotes capture what operational excellence actually looks like in practice.

On defining excellence

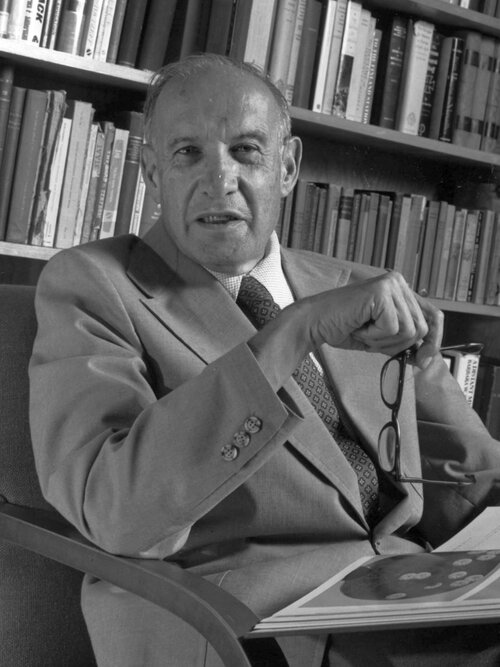

Management Consultant & Author

1909-2005

Austrian-American management consultant widely regarded as the father of modern management. His writings on management theory influenced business practices across the world and helped establish management as a legitimate discipline.

Jeff McNeill, CC BY-SA 2.0, via Wikimedia Commons

Efficiency is doing things right; effectiveness is doing the right things.

— Peter Drucker

Drucker made this distinction in the 1960s, and organizations still confuse the two. You can be incredibly efficient at the wrong work. You can optimize a process that should not exist.

Operational excellence requires both. First, determine if you are doing the right things. Then do them efficiently. The order matters. Tallyfy customers often discover during process mapping that entire workflows should be eliminated, not optimized.

There is nothing so useless as doing efficiently that which should not be done at all.

— Peter Drucker

This is Drucker at his most provocative. Before you perfect an operation, ask: should it exist?

I have watched companies spend months optimizing processes that added no value. They got faster at waste. The best operational improvement is often deletion.

Statistician & Quality Management Pioneer

1900-1993

American engineer, statistician, and management consultant who taught Japanese manufacturers post-WWII quality methods. His 14 Points for Management and concept that 85% of problems are systemic transformed manufacturing worldwide.

Public domain, via Wikimedia Commons

Quality is everyone’s responsibility.

— W. Edwards Deming

Deming rejected the idea that quality belongs to a quality department. When quality becomes everyone’s job, it becomes no one’s excuse.

This is why we built Tallyfy to involve everyone in process execution. Not just managers reviewing dashboards. The people doing the work are the first line of quality assurance.

On execution discipline

CEO of Berkshire Hathaway

1930-present

American investor and CEO of Berkshire Hathaway, widely regarded as one of the most successful investors in history. Known for his long-term value investing philosophy and candid shareholder letters on business principles.

Mark Hirschey, CC BY-SA 2.0, via Wikimedia Commons

The difference between successful people and really successful people is that really successful people say no to almost everything.

— Warren Buffett

Buffett is talking about personal productivity, but the principle applies directly to operations. Excellence comes from focus. Companies that try to be excellent at everything are excellent at nothing.

The most operationally excellent companies I have observed do fewer things. They just do them extraordinarily well. In discussions we have had with COOs at mid-size professional services firms, the companies that achieve excellence often start by eliminating 20-30% of their processes before optimizing what remains.

Chains of habit are too light to be felt until they are too heavy to be broken.

— Warren Buffett

Operational habits compound. Good habits create excellence over time. Bad habits create dysfunction that becomes impossible to untangle.

This is why standardizing processes early matters. The habits form whether you design them or not. Better to design them intentionally.

Someone’s sitting in the shade today because someone planted a tree a long time ago.

— Warren Buffett

Operational excellence is not built in a quarter. It is built over years of consistent improvement. The companies with exceptional operations today started building them years ago.

We built Tallyfy for the long game. Not quick wins that fade. Sustainable operational improvement that compounds.

On systems thinking

Statistician & Quality Management Pioneer

1900-1993

American engineer, statistician, and management consultant who taught Japanese manufacturers post-WWII quality methods. His 14 Points for Management and concept that 85% of problems are systemic transformed manufacturing worldwide.

Public domain, via Wikimedia Commons

A bad system will beat a good person every time.

— W. Edwards Deming

Deming told this to executives who blamed workers for quality problems. His insight was radical: 85% of problems come from the system, not the people in it.

When operations fail, the reflexive response is to blame individuals. But if the system is broken, replacing people changes nothing. Fix the system first.

In God we trust; all others must bring data.

— W. Edwards Deming

Deming insisted on data-driven decisions. Not opinions. Not intuition. Not HiPPO (highest paid person’s opinion). Data.

Operational excellence requires measurement. You cannot improve what you cannot see. Tallyfy tracks every process automatically, so the data exists without manual reporting.

Creator of Theory of Constraints

1947-2011

Israeli business management guru who developed the Theory of Constraints. His novel 'The Goal' became one of the best-selling business books ever, teaching constraint management through storytelling.

Wikimedia Commons, CC BY-SA 3.0

The goal is not to improve one measurement in isolation. The goal is to reduce operational expenses AND reduce inventories AND increase throughput simultaneously.

— Eliyahu Goldratt

Goldratt’s Theory of Constraints teaches that optimizing one metric while ignoring others creates false progress. Real operational excellence improves the whole system.

Companies often improve response time by adding staff, which increases costs. Or reduce costs by cutting quality, which increases rework. Excellence finds ways to improve multiple dimensions simultaneously.

Every action that does not bring the system closer to its goal is a waste of time and resources.

— Eliyahu Goldratt

This is the essence of lean thinking applied to operations. Every step in every process is either moving you toward your goal or it is waste.

When we help companies map their processes in Tallyfy, the waste becomes visible. Steps that seemed necessary often serve no purpose when examined against the actual goal.

On building culture

CEO of Microsoft

1967-present

Indian-American CEO of Microsoft since 2014, credited with transforming the company's culture from competitive infighting to collaborative growth mindset. His leadership tripled Microsoft's market value.

Microsoft, CC BY-SA 4.0, via Wikimedia Commons

Our industry does not respect tradition. It only respects innovation.

— Satya Nadella

Nadella transformed Microsoft’s culture from cutthroat competition to collaborative growth. The operations that worked in the past will not work in the future.

Operational excellence requires continuous adaptation. What worked last year may be obsolete now. At Tallyfy, we’ve seen that the companies that thrive treat their operations as living systems, not fixed procedures.

Hit refresh on individual mindset, on company culture, on products.

— Satya Nadella (paraphrased from Hit Refresh, 2017)

Nadella’s turnaround of Microsoft was not about new products. It was about refreshing how the company operated. Culture change preceded product change.

The operations team sets the tone. When operations resist change, the whole company stagnates. When operations embrace continuous improvement, innovation follows.

The learn-it-all does better than the know-it-all.

— Satya Nadella

This phrase defined Microsoft’s cultural transformation. Excellence comes from curiosity, not certainty. The best operations teams question their own processes.

We built feedback loops into Tallyfy because operational knowledge should flow from the people doing the work. They see what is broken. They know what could be better.

On measurement and improvement

What gets measured gets managed, but what gets measured badly gets managed badly.

— Variation on Drucker (common business wisdom)

The original Drucker quote is often misused to justify measuring everything. But measuring the wrong things creates worse outcomes than measuring nothing.

Operational excellence requires careful selection of metrics. Measure outcomes, not just activity. Measure value delivered, not just tasks completed.

The bottleneck is always at the top of the bottle.

— Peter Drucker

Drucker pointed out that operational constraints often come from leadership, not the front line. When executives create broken incentives or unclear priorities, excellence becomes impossible.

The best operations leaders I have seen protect their teams from organizational dysfunction. They create clarity even when the company creates chaos.

Father of the Toyota Production System

1912-1990

Japanese industrial engineer who developed the Toyota Production System, the foundation of Lean manufacturing. His innovations in just-in-time production and waste elimination revolutionized manufacturing globally.

Wikimedia Commons, CC BY-SA 4.0

Costs do not exist to be calculated. Costs exist to be reduced.

— Taiichi Ohno

Ohno’s Toyota Production System was relentlessly focused on waste elimination. Accounting tells you what you spent. Operations determines whether you needed to spend it.

This mindset shift transforms how companies think about operations. Every cost is a question: is this necessary? Could it be reduced? Should it exist at all?

The Toyota style is not to create results by working hard. It is a system that says there is no limit to people’s creativity.

— Taiichi Ohno

Ohno rejected the idea that operational excellence comes from working harder. It comes from working smarter. Creativity is not just for product teams. It belongs in operations.

The best process improvements at Tallyfy customers come from front-line workers who see opportunities that managers miss.

On consistency and standards

Founder of Kaizen Institute

1930-present

Japanese organizational theorist who introduced the concept of Kaizen (continuous improvement) to the Western world. His book 'Kaizen: The Key to Japan's Competitive Success' defined the philosophy of incremental, ongoing improvement.

Kaizen Institute, CC BY-SA 4.0, via Wikimedia Commons

Where there is no standard, there can be no kaizen.

— Masaaki Imai, Kaizen: The Key to Japan’s Competitive Success (1986)

You cannot improve chaos. Standardization creates a baseline that makes improvement possible.

This does not mean rigid bureaucracy. It means defining how things currently work so you can make them work better. Without a standard, improvement is just random variation.

Kaizen means ongoing improvement involving everybody, without spending much money.

— Masaaki Imai

Excellence is not an expensive initiative. It is a daily habit. Small improvements by everyone compound into dramatic results.

We designed Tallyfy so that anyone can suggest process improvements, not just managers. When improvement becomes everyone’s job, excellence becomes inevitable.

On leadership in operations

Former CEO of PepsiCo

1955-present

Indian-American businesswoman who served as CEO of PepsiCo from 2006 to 2018. Her 'Performance with Purpose' strategy integrated social responsibility with business performance, demonstrating that values and profits can coexist.

World Economic Forum, CC BY-SA 2.0, via Wikimedia Commons

The one thing I have learned as a CEO is that leadership at various levels is vastly different. When I was leading a function or a business, there were certain demands. But when you are in the job of leading an entire organization, there are far more variables that affect the outcomes.

— Indra Nooyi

Nooyi led PepsiCo’s operations through massive transformation. Her insight: operational leadership requires different skills at different scales.

What works for a team does not work for a division. What works for a division does not work for an enterprise. Excellence at each level requires different approaches.

The distance between number one and number two is always a constant. If you want to improve the organization, you have to improve yourself.

— Indra Nooyi

Operational excellence starts with leadership. The organization cannot outperform its leaders’ commitment to improvement.

This is not about heroics. It is about modeling the behavior you expect. When leaders cut corners, teams cut corners. When leaders demand excellence, teams deliver it.

What operational excellence actually requires

After years of working with operations teams and building Tallyfy, the pattern is clear:

Excellence is consistency, not heroics. The best operations are boring. They work the same way every time. The drama is removed.

Measurement enables improvement. Without data, you are guessing. The operations that improve fastest are the ones that track everything.

People make systems work. Technology enables excellence. People create it. Invest in both.

Simplicity beats complexity. The most excellent operations are often the simplest. Complexity creates failure points.

Improvement never stops. Excellence is not a destination. It is a direction. The moment you stop improving, decline begins.

These principles shaped how we built Tallyfy. Not as another task manager. As an operational excellence platform that makes consistency easy and improvement inevitable.

Because the goal is not to track work. The goal is to make work work better.

About the Author

Amit is the CEO of Tallyfy. He is a workflow expert and specializes in process automation and the next generation of business process management in the post-flowchart age. He has decades of consulting experience in task and workflow automation, continuous improvement (all the flavors) and AI-driven workflows for small and large companies. Amit did a Computer Science degree at the University of Bath and moved from the UK to St. Louis, MO in 2014. He loves watching American robins and their nesting behaviors!

Follow Amit on his website, LinkedIn, Facebook, Reddit, X (Twitter) or YouTube.

Automate your workflows with Tallyfy

Stop chasing status updates. Track and automate your processes in one place.