Summary

The best companies obsess over operations management. The mediocre ones outsource it.

- Michael Hammer, Business Process Pioneer

- Based on feedback from hundreds of operations teams we work with, the biggest wins come from eliminating tribal knowledge and making processes visible - one enterprise finance team calculated $7,500 lost per quarter from a single poorly-coordinated process

- The most successful operations managers master both technical skills (process design, Six Sigma, supply chains) and human skills (change management, team motivation) - McKinsey research confirms the human side accounts for 70% of transformation success

- Modern operations has evolved beyond manufacturing - it now orchestrates technology, people, and processes across every department to create competitive advantage, with some teams managing workflows across 80+ countries and 20+ languages

- Start with one painful process everyone hates, fix it completely, then build momentum - we have seen teams achieve 75% efficiency gains by standardizing just one critical workflow

Operations management is the administration of business practices aimed at ensuring maximum efficiency within a business, which in turn helps to improve profitability.

It involves resources from staff, materials, equipment, and technology, converting these inputs into efficient and effective outputs on both day-to-day and strategic levels within an organization.

If you think that sounds super theoretical, we agree - it does. As with most business buzzwords, it can be a bit hard to understand in terms of REAL practice. And that is what we are going to simplify - how to use operations management to improve your business.

In this guide, you are going to learn:

- What is operations management, exactly?

- What does an operations manager do?

- The 4 Vs framework that defines your operations

- Skills you need to succeed in operations

- Why Operations management is important

- How to put operations management into practice with 4 of the most popular methodologies

What is operations management

Operations management is basically people management. Most business departments focus on very specific goals - marketing means getting more sales for your business, HR keeps your employees happy, and so on.

Operations management, on the other hand, involves getting the most out of your company resources. These can involve your employees (doing more work that creates value), technology (maximum efficiency in manufacturing, for example), equipment (help employees do more work), and so on.

As you have probably figured, operations management involves dealing with a lot of different areas. Hence, it is important for your COO (chief operations officer) to have a background in all sorts of disciplines, from manufacturing to people-management.

Actually, here is something most articles will not tell you: operations management emerged from early 20th-century manufacturing practices and became increasingly important after World War II. Military logistics research highlighted the power of process optimization - and businesses took notice. Fast forward to today, and it has evolved into something far more comprehensive than just factory floor management.

What does an operations manager do

Depending on the organization, an operations manager can be responsible for a lot of different things.

Unlike other executive positions, operations management is cross-department. A CMO specifically works with the marketing department, CFO with finance, and so on. A COO, on the other hand, might need to work with just about every department (if there is need for it).

In most cases, their work involves:

- Process Design - Figuring out the exact steps needed to be carried out so that the organization meets its business goals. This can mean helping plan out a one-time project or creating procedures for repeatable work. A real-life example of operations in projects would be, for example, creating a timeline for developing some software for the client. For a process example, the COO could create a structured employee onboarding procedure to make the whole onboarding more efficient. Learn how to create your first operational template here.

- Standard Management - Helping create and optimize budgets, scheduling equipment maintenance, ensuring that the employees are following standard procedures, etc. Document your operations properly with the right tools.

- Process Improvement and Optimization - Most businesses have a "do not fix what is not broken" policy towards their processes. More often than not, though, you could potentially get a lot more from your business if you constantly check on your processes. The COO is supposed to make sure that all your processes are as efficient as they can be. Discover systematic approaches to process improvement.

But here is what they do not teach in business school: the best operations managers spend 60% of their time on the human side - getting buy-in, managing change resistance, building improvement culture. The technical stuff? That is the easy part. In our conversations with operations leaders across industries, this pattern comes up repeatedly - McKinsey research confirms the human element determines success or failure far more than the tools or frameworks chosen.

We have seen this firsthand with a global aerospace team managing expertise transfers - their structured 2-24 month knowledge handover process prevented years of institutional knowledge from walking out the door when senior engineers retired. Without it, new hires were essentially starting from scratch.

The 4 Vs of operations - understanding your operational reality

Every operation is different. McDonald's and a boutique consulting firm both have operations, but they could not be more different. That is where the 4 Vs framework comes in - it is how you understand what makes your operations unique.

Volume

How much do you produce? High volume operations (think Amazon warehouses) focus on standardization and efficiency. Low volume operations (custom software development) focus on flexibility and expertise.

The thing is, most mid-size companies fall somewhere in between. You are not cranking out millions of widgets, but you are also not doing everything custom. This middle ground is actually where smart automation makes the biggest difference - standardizing what you can while keeping flexibility where you need it.

Variety

How many different products or services do you offer? High variety means complexity. Each variation needs different processes, skills, maybe even equipment.

Here is the catch: variety kills efficiency if you are not careful. The solution? Template-based operations. Create standard frameworks that can flex for different needs without starting from scratch each time. Manage variety with flexible workflows.

Variation in demand

Does your workload look like a roller coaster or a flat line? Most businesses deal with peaks and valleys - tax season for accountants, holidays for retail, Monday mornings for IT help desks.

Smart operations managers build capacity for peaks without wasting resources in valleys. This might mean cross-training staff, using flexible scheduling, or automating routine tasks so humans can handle the complex stuff when things get busy. Learn more about scaling operations with consistent processes.

Visibility

How much can customers see of your operations? In a restaurant, they see everything. In a data center, they see nothing.

Higher visibility means higher pressure to get things right every time. But here is the opportunity: making your operations more visible internally (even if customers cannot see them) drives accountability and improvement. When everyone can see the workflow status, bottlenecks become obvious. Problems get fixed faster.

A global food and beverage company we worked with had their procurement team constantly asking "Where is my purchase order?" - they had SAP, Ariba, and multiple other systems but no unified view of order status. The lack of visibility across disconnected systems meant no one could answer a simple question: has this supplier been paid?

Why operations management is important

In smaller companies, operations are very simple and straightforward. Everyone takes part in managing the processes, and more or less, things go smoothly.

The same, however, does not apply to companies with 20+ employees. That is when things start getting complicated. You cannot just rely on your employees to do work right - you need to have standardized procedures to ensure that everything as efficient as possible.

Feedback we have received from operations teams consistently highlights the same pain points. Here is what happens without good operations management:

- The knowledge cliff - When Sarah from accounting leaves, nobody knows how month-end closing actually works. Three months of chaos while someone figures it out. This tribal knowledge problem costs companies millions.

- The efficiency leak - Death by a thousand paper cuts. Each inefficiency seems small - an extra approval here, a redundant data entry there. Add them up? You are hemorrhaging 30% of your capacity. One global enterprise told us their 163-person operations team was costing $11M+ annually with significant rework and duplication.

- The quality lottery - Different people, different quality. Customer experience depends on who handles their case. A quantitative trading firm we worked with found 4-10x productivity differences between staff on the same procedures - simply because best practices were not documented consistently.

If done right, operations management can lead to:

Better Output - The operations manager optimizes and improves processes that have a heavy impact on the product or service. This usually leads to higher output, lower defect rates, lower costs, and so on. Achieve operational excellence with proven methods.

Competitive Advantage - Better output leads to a better product or service. This allows your organization to stand out from the competition, gaining new customers.

Higher Profits - As a combination of the first two, you end up improving the company bottom line and making more profits.

But here is the real kicker: good operations management makes work not suck. Employees stop fighting broken processes. They stop doing redundant work. They actually get to use their brains instead of following outdated playbooks. Build an operations manual that actually gets used.

Core frameworks and methodologies

Sadly, there is no step-by-step guide to operations management. Unlike most fields, it involves knowing a lot of different things, from finance to HR.

Knowing your way around process management, though, will make operations significantly easier.

While there are a lot of different approaches there, the following 4 are the most popular.

Business process management (BPM)

BPM is something every operations manager should have a good hang of. Chances are, you have heard the term before - and no, it is not just another buzzword.

Business process management is the methodology of constantly analyzing, improving and automating processes. It is not something you do just once, though - you need to be on a constant lookout for potential improvements.

Putting that into practice, you should have a general idea of what the BPM lifecycle consists of. i.e, the exact steps you need to take to work on any given process.

The steps are:

- Design - Every company has processes. Not all of them, however, are really outlined. More often than not, they are implicit. The "design" part means identifying a process and figuring out where it starts, what it consists of, and where it ends. To learn more about business process design, check out our guide.

- Modeling - Once you have identified a process, you need to put it down on paper. Without something to look at, the analysis part can be quite hard. Usually, you would go for a workflow diagram if the process is simple, or one of the many business process mapping techniques, if it is not. To learn more about business process modeling, check out our guide.

- Analysis - Now that you have a workflow diagram ready, you can start analyzing it. Are there any steps within the process that do not really add value? Are there any ways to remove them? Are there any steps you could just automate using software? To learn more about business process analysis, check out our guide.

- Monitoring - You cannot improve a process without knowing how well it is performing as-is. Plus, you should also be able to figure out whether the changes you are making have a positive impact or not. So, gather the benchmark data for the process as-is and compare it to the data you get post-improvements. Learn how to use analytics for process insights.

- Improving or Automating - Use the insights you have identified in the "analysis" step to make changes to the process. You can either improve it by working with the process steps or automate certain steps using software or hardware. To learn more about business process improvement or automation, check out our guides. See how process improvement software can accelerate your efforts.

Quick reality check: Gartner research shows that most BPM initiatives fail because they are too ambitious. Based on hundreds of implementations we have supported, the pattern is clear - start with one annoying process everyone hates. Fix that. Build momentum. Then tackle the bigger stuff. A publishing team we worked with scaled from 3 to 60 people by obsessively standardizing their core workflows before growing. Learn about continuous process improvement approaches.

Business process reengineering

Sometimes, improving processes is not the most efficient thing you can do. Instead, you want to re-engineer it (not just a business buzzword, we promise!). Meaning, instead of improving a process, you re-create it from scratch.

In most cases, this is done with the help of technology. After all, you cannot really change something fundamentally just like that.

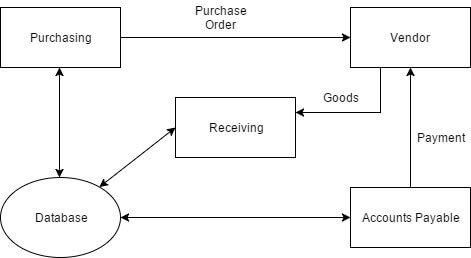

To give you a better idea of how this works, we will look into an example of how Ford completely re-engineered their accounts payable department.

The major problem was that the department was significantly overstaffed. They employed 500 people, as opposed to 5 in the same department at Mazda (a partner company).

Ford launched a BPR initiative to figure out why they were underperforming. The old process worked as follows:

- The purchasing department receives a purchase order. The copy is forwarded to the accounts payable

- Material control receives the goods and send a copy of the delivery document to accounts payable

- The vendor sends a receipt to accounts payable

- The accounts payable matches the three separate documents, and only then is the payment issued

Or, as it would look like in a graph...

As you have probably already guessed, this makes the whole thing extremely time-consuming. Hence, you would need a lot of employees to keep doing this on the go.

Realizing this, Ford completely re-engineered the process. Instead of doing everything manually, they created an online database which was used to match the different documents.

Accordingly, an operations manager can use business process reengineering to make significant improvements to company processes.

The lesson here? Sometimes incremental improvement is not enough. When a process is fundamentally broken, you need to blow it up and start over. Just make sure you have buy-in first - nobody likes surprises.

Six Sigma and lean thinking

The two methodologies we have mentioned until now dealt with business processes.

Six Sigma, on the other hand, traditionally focused on manufacturing processes. The main idea behind it is minimizing defect rates - for every million opportunities, you should not have more than 3.4 inefficiencies.

But here is the evolution: Six Sigma is not just for factories anymore. Service companies use it to reduce errors in everything from hospital procedures to software deployments. You can measure any process with sigma levels.

While there are a lot of Six Sigma tools out there, DMAIC is one of the most popular ones. The methodology helps perfect your processes and consists of 5 steps:

- Define - Outline what the issue with any given process is. Decide on the improvement goal and which tools or resources you are going to use. Get a practical introduction to DMAIC here.

- Measure - Look at the process as-is and measure its performance. Once you know what the metrics are, you will have a better idea on how to improve them.

- Analysis - Find the root cause of the issue. Why is the process underperforming? Learn simple root cause analysis techniques.

- Improvement - Once you have identified the problem, try finding potential solutions.

- Control - Implement the new process on a small scale and benchmark the new results to the old.

And let us not forget Lean thinking - Six Sigma's cousin. While Six Sigma obsesses over quality, Lean obsesses over waste. The magic happens when you combine them. Lean thinking works beautifully in office environments, not just factories. Industry experience shows that organizations combining both approaches see stronger results than those using either alone. Learn more about Lean Six Sigma methodologies and lean management principles.

The seven wastes to eliminate:

- Overproduction - Making more than needed (reports nobody reads)

- Waiting - Time lost waiting for approvals, decisions, information

- Transportation - Moving stuff around unnecessarily (data through 10 systems)

- Over-processing - Doing more than the customer values (gold-plating)

- Inventory - Work piling up in queues

- Motion - Unnecessary movement (walking to printers, switching between apps)

- Defects - Mistakes that need fixing

Supply chain management

Another major aspect of modern operations management is supply chain management.

As organizations have become more complex and much more international in their scope, the strategic process by which materials, goods and information flow between suppliers, businesses and consumers has become an industry in itself.

Keeping the supply chain healthy and moving is in the interests of everyone involved, but there are many factors that can slow things down.

Modern supply chain challenges nobody predicted:

- The visibility problem - You can track a pizza delivery better than a $100,000 shipment. Companies are finally fixing this with real-time tracking, but most are still flying blind.

- The resilience test - Remember when one ship blocked the Suez Canal and broke global trade? Your supply chain needs Plan B, C, and D.

- The sustainability pressure - Customers want to know where stuff comes from and how it is made. Carbon footprints matter now. ESG is not just for annual reports anymore.

Compared to some of the other aspects of operations management mentioned so far, supply chain management is relatively recent, with the term only originating in 1982 and not becoming commonly used until the 1990s.

Supply chain management oversees each touch point of a company's product or service, from its creation to the sale, and this makes it an important aspect to manage as getting it right or wrong affects efficiency, costs, and profits.

Essential skills and team management

Forget the generic "leadership and communication" stuff every article mentions. Based on patterns we see across operations teams using our platform, here is what actually matters in the trenches:

Technical skills that pay the bills

- Data analysis - Not just Excel. You need to spot patterns in chaos, turn metrics into stories that get executives to act. If you cannot prove ROI with numbers, your improvements die in committee. Calculate your operational ROI here.

- Process mapping - But here is the twist: skip the complex flowcharts that nobody reads. Simple, visual workflows that everyone understands beat perfect BPMN diagrams every time.

- Systems thinking - Everything connects. Speeding up one process might break three others. Great ops managers see the whole puzzle, not just individual pieces.

- Financial fluency - You are not the CFO, but you better speak their language. Every process improvement needs a business case.

The human skills nobody talks about

- Change psychology - People hate change. Even good change. The ability to make improvement feel like their idea? That is gold.

- Political navigation - Operations touches every department. You are going to step on toes. Knowing whose toes can be stepped on (and whose cannot) determines your survival.

- Simplification instinct - The urge to add complexity is strong. Great ops managers constantly ask: "How can we make this simpler?"

- Patience of a saint - Real improvement takes months, sometimes years. Quick wins keep you employed while you work on the big stuff. Master continuous improvement methodologies.

Modern operations skills for the digital age

- Automation judgment - Knowing what to automate and what to keep human. Hint: it is not about the technology, it is about the value. Explore intelligent automation options.

- Remote operations management - Managing processes when your team is distributed across time zones. Integration with collaboration tools becomes critical.

- Continuous improvement facilitation - Building systems that improve themselves through feedback loops and team input. Creating this culture is the real challenge.

Modern operations management trends

Let us talk about what is really happening in operations right now - not the consultant slideware, but the actual changes:

The automation reality check

Everyone is talking about AI and automation. Here is what is actually working:

- Smart routing - Tasks automatically go to the right person based on workload and expertise. No more manual assignment.

- Predictive maintenance - Equipment tells you it is going to break before it does. Works for servers, HVAC, even coffee machines.

- Intelligent document processing - Invoices, contracts, forms - they read themselves now. Humans just handle exceptions.

But here is the thing: full automation is usually wrong. The sweet spot is augmentation - technology handling the boring stuff so humans can do human stuff. This hybrid approach actually works.

The scale question matters too. A telecommunications company we evaluated needed to support 10,000+ users initiating workflows, but only expected 300 actual workflows per year - that ratio tells you everything about how to design the system. Meanwhile, a financial services firm with thousands of advisor locations needed the opposite: fewer users, but each running the same onboarding workflow hundreds of times.

Industry-specific operations solutions are emerging too. Healthcare organizations use specialized healthcare process management, while pharmaceutical companies implement pharmaceutical operations standards. Professional services firms are adopting professional services automation to standardize their unique workflows.

The sustainability shift

Operations managers are now chief sustainability officers by default. You are measuring:

- Carbon per unit produced

- Waste reduction percentages

- Energy efficiency improvements

- Circular economy contributions

Not because it is trendy. Because customers demand it, regulators require it, and honestly? It usually saves money.

The flexibility imperative

Remember when operations meant standardization? Now it is about managed flexibility:

- Processes that adapt to context

- Teams that reconfigure for different projects

- Systems that scale up and down with demand

- Workflows that work across office, home, and everywhere in between

Converting rigid processes into flexible templates is the new operations superpower.

Implementation and best practices

As we have already discussed, one of the biggest aspects of operations management is process improvement.

If you are doing this manually, it can be a bit rough:

- Your employees will not always follow the best practice with the process

- You will need to map business processes and store them manually

- You will have to keep continuously track process metrics

Why traditional BPM software fails

Let us finish up here by talking about how people actually run operations. It used to be via BPM software. "Old BPM" software is tired and broken. It never worked for business users. Here is why:

- Users are now deciding to buy software themselves. Old BPM was bought by your IT department, who did not generally care about user experience - as long as it was made by a large/boring company.

- Cloud tools are now free to try by anyone, anytime. With Old BPM you had to call sales and wait for 50 questions just to look at it and finally decide it sucks.

- People want to share workflows with clients. With Old BPM you were stuck with trying to automate internal processes only. Your clients would be very scared and run a mile from it.

- People expect to integrate cloud tools without IT. With Old BPM you had get engineers to write code to make a simple integration. That has now become a drag-and-drop service.

- People expect to work on phones. This means giant, clunky flowcharts in Old BPM are dead - because they do not fit on your phone screen - and only define "the perfect process".

- People are tired of flowcharts. Old BPM was all about the high priest telling you how a process can/will be done, and you would obey. Now - modern workers and teams are paid to collaborate.

- People expect all the benefits of the cloud. Old BPM was never cloud-born and was never designed for the cloud. And that creates a massive bunch of missed opportunities.

- Companies of all sizes need process management - and never had it. Since Old BPM was so expensive and complicated, only large companies could afford it. The rest of us were left out.

- People are excited about AI - but confused about where to begin. With Old BPM you have zero chance of using AI without an army of engineers. With cloud-born systems like Tallyfy - it is childs play to use any AI you like to run amazing automations for photos, voice, video and more.

What modern workflow management looks like

Look, the truth about operations software is this: most of it is built for the Fortune 500. They have different problems than you do. They need military-grade complexity. You need something your team will actually use.

That is where modern workflow management comes in. Instead of:

- Enterprise-level implementations that take 18 months

- Consultants who have never actually run operations

- Flowcharts that look like subway maps

- Training sessions that everyone forgets

You get:

- Setup in hours, not months

- Workflows everyone understands

- Changes without calling IT

- Actual adoption by actual humans

To make your life as an operations manager easier - try using Workflow Management Software.

Tallyfy is a central hub for all of your company processes - you can see how well each process is going, whether there are any delays, and so on. This makes process management and improvement significantly easier.

We built it because we were tired of the enterprise complexity. Sometimes simpler is actually better. Take a tour of how it actually works. Or if you want to see the difference, check how we compare to traditional solutions.

Your next steps in operations management

Operations management is not going away. If anything, it is becoming more critical as businesses get more complex, more distributed, more digital.

The winners will not be the companies with the most sophisticated systems. They will be the ones who figure out how to make operations invisible - so smooth that nobody notices them.

Start here:

- Pick your most painful process - The one everyone complains about

- Map it simply - No fancy diagrams, just steps

- Find the stupidest part - There is always something obviously dumb

- Fix that one thing - Do not boil the ocean

- Build on success - Use momentum to tackle bigger problems

Want to see how modern operations management actually works in practice? Create your first workflow template in 10 minutes. Or if you are ready for a deeper dive into continuous improvement methodologies like Kaizen, we have got you covered.

Remember: perfect is the enemy of done. Start improving something today. Even if it is small. Especially if it is small.

Because operations management is not about building the perfect system. It is about making tomorrow slightly less chaotic than today. And doing that every single day.

Frequently asked questions

What are the 4 types of operations management?

There are different ways to classify operations, but the most useful framework looks at process types. You have got job shops (custom work, like a tailor), batch shops (making stuff in groups, like a bakery), assembly lines (continuous production, like car manufacturing), and continuous flow (never stops, like oil refineries). Most modern businesses actually blend these - you might have assembly-line customer service with job-shop product customization. The key is matching your operation type to what customers actually want.

What are the 4 Vs of operations management?

The 4 Vs help you understand what makes your operations unique. Volume (how much you produce), Variety (how many different things), Variation (how demand changes), and Visibility (how much customers see). A hospital emergency room? High variety, high variation, high visibility, medium volume - total chaos to manage. A data center? High volume, low variety, low variation, zero visibility - much simpler. Understanding your 4 Vs tells you what kind of operations strategy you need.

What are the 5 key functions of operations management?

Operations managers juggle five core functions. Planning (what needs to happen), organizing (getting resources in place), staffing (having the right people), directing (making it actually happen), and controlling (keeping things on track). Think of it like running a restaurant - you plan the menu, organize the kitchen, staff the shifts, direct during service, and control quality throughout. Miss any of these and dinner service falls apart.

What are the 10 strategic operations management decisions?

There are ten major decision areas every operations manager faces: product design (what to offer), quality management (how good it needs to be), process and capacity design (how to make it), location strategy (where to operate), layout design (how to arrange things), human resources (who does what), supply chain management (where stuff comes from), inventory (how much to keep), scheduling (when things happen), and maintenance (keeping things running). Each decision affects the others - change your product design and you might need to reorganize your entire layout.

What skills does an operations manager need?

Beyond the obvious stuff like organization and communication, successful operations managers need three critical skills nobody talks about. First, pattern recognition - spotting inefficiencies others miss. Second, political navigation - operations touches every department, so you need diplomatic skills. Third, simplification instinct - the ability to make complex things simple without losing effectiveness. Technical skills matter, but these human skills determine whether you will actually succeed.

What is the difference between operations management and project management?

Project management is like planning a wedding - unique event, specific end date, then it is done. Operations management is like running the wedding venue - ongoing, repetitive, never really "done." Project managers worry about delivering on time and budget. Operations managers worry about doing it efficiently forever. You might use project management to set up a new production line, then operations management to run it daily.

How much do operations managers make?

The median salary sits around $99,000 according to Bureau of Labor Statistics data, but that is misleading. Entry-level operations coordinators might start at $45-60K. Experienced operations managers in tech or finance can clear $150K. Director of Operations roles often hit enterprise-level compensation. Location matters hugely - San Francisco pays double what Kansas City does. Industry matters too - tech and pharma pay more than retail or hospitality. The real money comes when you can prove you save or make the company money through operational improvements.

What education do you need for operations management?

Most operations managers have a bachelor degree in business, engineering, or something analytical. About 30% have MBAs, though it is rarely required. What matters more? 5-8 years of experience actually running things. Certifications like Lean Six Sigma or PMP can help, but they are not magic bullets. The dirty secret? Some of the best operations managers started on the floor and worked their way up. They know how things actually work, not just how they should work in theory.

Why do operations management initiatives fail?

Three reasons kill most operations improvements. First, trying to change everything at once - it is too much, people resist, nothing sticks. Second, ignoring the human side - perfect processes mean nothing if nobody follows them. Third, lack of executive support - when leadership does not care, neither does anyone else. McKinsey transformation research consistently finds executive sponsorship as the top predictor of success. The fix? Start small, get buy-in, show wins, then expand. And for heaven sake, make sure the CEO actually cares before you start.

What is the difference between operations management and supply chain management?

Operations management is about what happens inside your walls - how you transform inputs into outputs. Supply chain management is about what happens outside - getting materials in, products out, and everything in between. They overlap significantly. Good operations managers need to understand supply chains because delays upstream wreck operations downstream. Think of operations as the engine and supply chain as the fuel system - both need to work for the car to run.

How is operations management changing with remote work?

Remote work broke traditional operations management. You cannot manage by walking around when nobody is in the office. The shift forced three big changes. First, from time-based to output-based management - who cares when work happens if it gets done? Second, from synchronous to asynchronous processes - everything does not need a meeting. Third, from implicit to explicit documentation - when knowledge is not in the hallway, it needs to be written down. Smart companies are finding remote operations can actually be more efficient - no commute time, fewer interruptions, better work-life balance leading to higher productivity.

What is the biggest mistake new operations managers make?

Trying to be the hero who fixes everything immediately. They come in, see all the problems, start seventeen improvement initiatives, overwhelm everyone, and accomplish nothing. Experienced operations managers know better. Pick one thing. Fix it completely. Use that success to build credibility. Then pick the next thing. Operations improvement is a marathon, not a sprint. Plus, you need to understand why things are broken before you can fix them - and that takes time to learn.

How does AI actually help operations management?

Forget the hype about AI replacing operations managers. Here is what actually works: AI for pattern recognition in data (spotting bottlenecks you would miss), predictive maintenance (knowing what breaks before it does), intelligent routing (sending work to the right person automatically), and document processing (reading invoices, contracts, forms). The real value? AI handles the analysis so you can focus on decisions. It is not about artificial intelligence replacing human intelligence - it is about augmenting it. See how AI agents actually work in operations.

How do you handle operations across multiple countries and languages?

Global operations are exponentially harder than local ones. Teams we work with managing operations across 80+ countries need to think about language (some processes need 20+ language variants), time zones (handoffs that span continents), local regulations (compliance varies wildly), and cultural differences (what counts as "urgent" differs by region). The solution is usually template-based standardization - create a core process that works everywhere, then allow local customization within guardrails. A major real estate services firm we supported needed workflows in 23+ languages for their global property inspections - the framework was identical, but field labels and instructions adapted per region.

How do you calculate the ROI of fixing a broken process?

Most people overcomplicate this. Start simple: how many hours per week does the current process waste? Multiply by the hourly cost of the people involved. One enterprise finance team did this math for their quarterly planning coordination - 50 hours wasted per quarter at $150/hour average cost equals $7,500 per quarter for just one process. That is $30,000 per year from a single broken workflow. Now imagine you have fifty broken processes. The numbers add up fast. Factor in error correction, missed deadlines, and frustrated employees, and the true cost is often 3-4x the direct time waste.

Ready to streamline your workflows?

See how Tallyfy makes workflow management simple and effective for teams of all sizes.

About the Author

Amit is the CEO of Tallyfy. He is a workflow expert and specializes in process automation and the next generation of business process management in the post-flowchart age. He has decades of consulting experience in task and workflow automation, continuous improvement (all the flavors) and AI-driven workflows for small and large companies. Amit did a Computer Science degree at the University of Bath and moved from the UK to St. Louis, MO in 2014. He loves watching American robins and their nesting behaviors!

Follow Amit on his website, LinkedIn, Facebook, Reddit, X (Twitter) or YouTube.